Anticorrosion coating for steel structure

A technology for anti-corrosion coatings and steel structures, applied in the field of coatings, can solve the problems of complex treatment, poor comprehensive anti-corrosion performance, poor coating durability, etc., and achieve the effects of simple preparation and construction process, excellent anti-corrosion performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

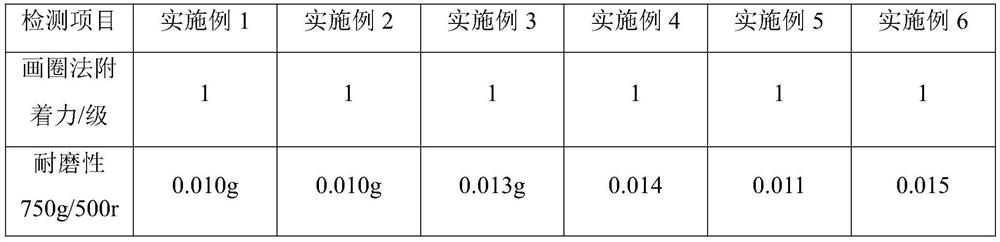

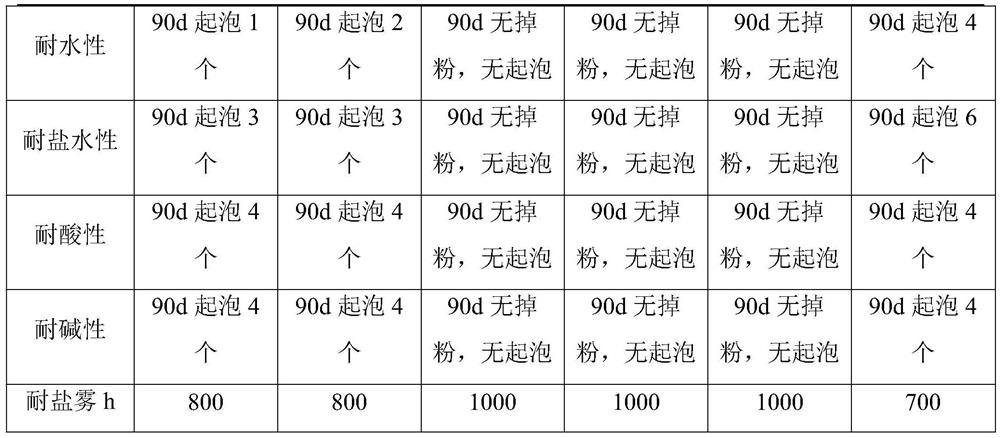

Examples

Embodiment 1

[0037] An anti-corrosion coating for steel structures is prepared by mixing component A and component B at a weight ratio of 5:1, wherein component B is an epoxy curing agent, and component A is prepared from the following raw materials in weight percentage : 20% modified epoxy resin emulsion, 35% modified graphene oxide hydrosol, 20% modified nanocomposite sol, 15% filler, 4% corrosion inhibitor, 2% anti-settling agent and 4% diluent;

[0038] Wherein, the preferred ketimine of epoxy curing agent;

[0039] The filler is one or more of kaolin, sericite powder, fly ash, and montmorillonite; sericite powder is preferred;

[0040] The corrosion inhibitor is preferably 2-mercaptobenzothiazole;

[0041] The anti-sedimentation agent is organic bentonite or white carbon black; preferably organic bentonite;

[0042] The diluent is one or more of ethanol, glycerol, and pentaerythritol, preferably pentaerythritol;

[0043] Its specific preparation method comprises the following steps...

Embodiment 2

[0052] A steel structure anti-corrosion coating is made by mixing component A and component B at a weight ratio of 4.8:1, wherein component B is an epoxy curing agent, and component A is prepared from the following raw materials in weight percentage : Modified epoxy resin emulsion 24%, modified graphene oxide hydrosol 35%, modified nanocomposite sol 20%, filler 10%, corrosion inhibitor 5%, anti-settling agent 2% and diluent 4%;

[0053] Wherein, the preferred ketimine of epoxy curing agent;

[0054] The filler is one or more of kaolin, sericite powder, fly ash, and montmorillonite; sericite powder is preferred

[0055] The corrosion inhibitor is preferably 2-mercaptobenzothiazole;

[0056] The anti-sedimentation agent is organic bentonite or white carbon black; preferably organic bentonite;

[0057] The diluent is one or more of ethanol, glycerol and pentaerythritol, preferably pentaerythritol.

[0058] Its preparation method specifically comprises the following steps:

[...

Embodiment 3

[0067] A kind of steel structure anticorrosion coating, it is characterized in that, described coating is made by mixing component A and component B with the weight ratio of 4.8:1, wherein, described component B is epoxy curing agent, and component A is made of Prepared from the following raw materials in weight percent: modified epoxy resin emulsion 32.5%, modified graphene oxide hydrosol 30%, modified nanocomposite sol 17.5%, filler 12.5%, corrosion inhibitor 3%, anti-settling agent 1.5% % and diluent 3%;

[0068] Wherein, the preferred ketimine of epoxy curing agent;

[0069] The filler is one or more of kaolin, sericite powder, fly ash, and montmorillonite; sericite powder is preferred

[0070] The corrosion inhibitor is preferably 2-mercaptobenzothiazole;

[0071] The anti-sedimentation agent is organic bentonite or white carbon black; preferably organic bentonite;

[0072] The diluent is one or more of ethanol, glycerol and pentaerythritol, preferably pentaerythritol....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com