Neutron radiation-resistant polyimide coating and preparation method and application thereof

A polyimide and coating technology, applied in the field of anti-neutron radiation polyimide coating and its preparation, can solve the problems of anti-neutron radiation effect and poor heat resistance, and achieve excellent anti-neutron radiation effect , expand the scope of application, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

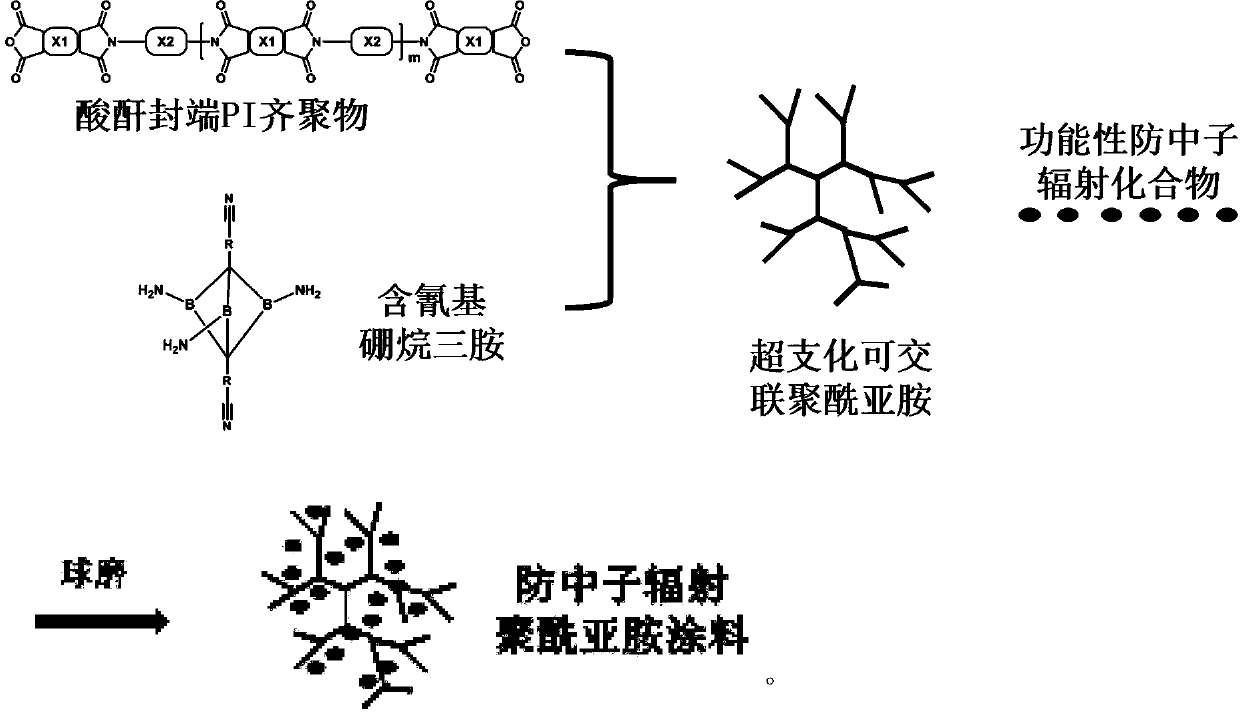

Method used

Image

Examples

Embodiment 1

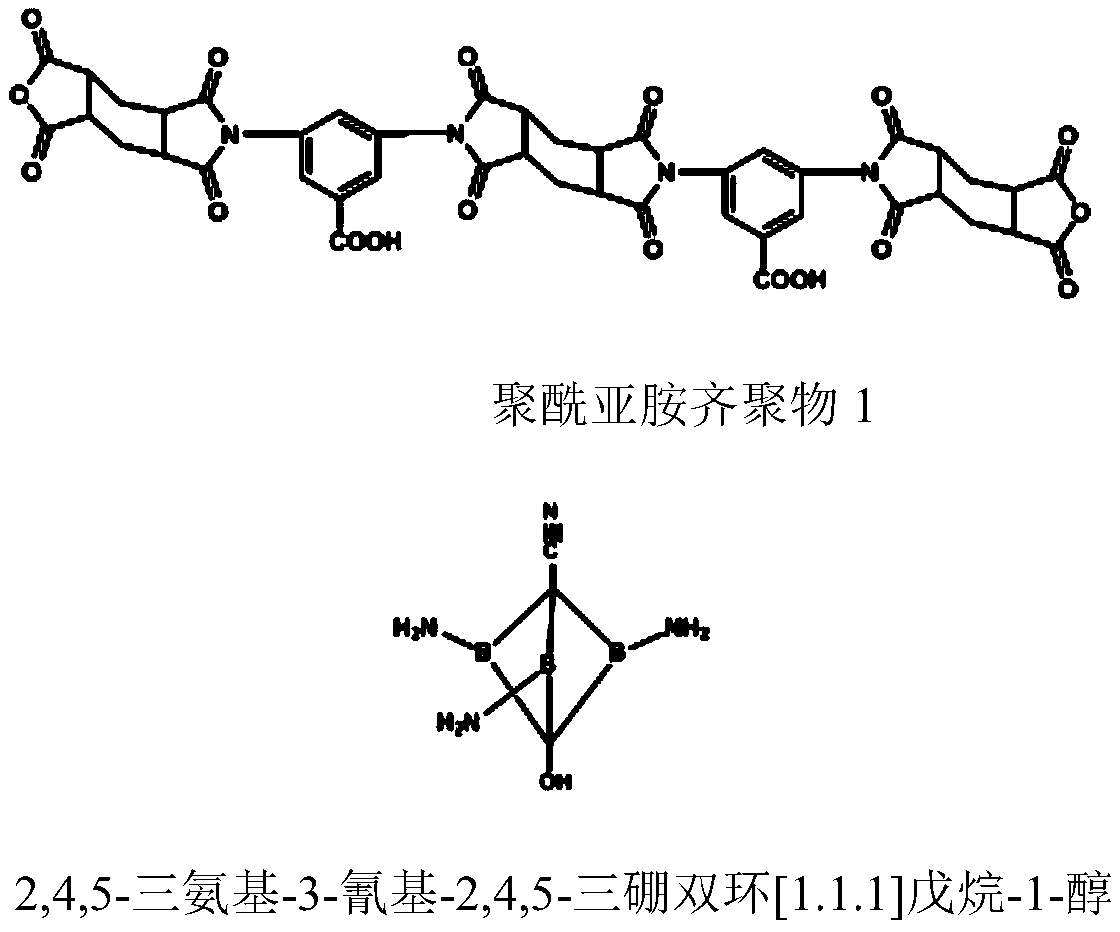

[0030] (1) Under nitrogen protection, in a three-necked flask, add 240mL of NMP, 48.8g (0.054mol) of anhydride-terminated oligomer 1 (structural formula as follows, purity >99%), 5.3g (0.036mol) of 2,4,5-triamino-3-cyano-2,4,5-triboronbicyclo[1.1.1]pentane-1-ol (structural formula as follows, Aladdin reagent, analytically pure), stirred at 5°C React for 10 hours; then raise the temperature to 115°C, 135°C, and 165°C for 1 hour respectively, and finally raise the temperature to 180°C and react at a constant temperature for 18 hours to obtain a hyperbranched polyimide solution with a solid content of 18%.

[0031]

[0032] (2) the hyperbranched polyimide solution (solid content 18%) that the silane coupling agent KH550 of 5g, the boron oxide of 0.5g, 0.05g, 220g step (1) gained are placed in planetary ball mill successively , ball milled at 50°C for 14 hours, and discharged to obtain a functional anti-neutron radiation polyimide coating.

[0033] Coating the polyimide fabric...

Embodiment 2

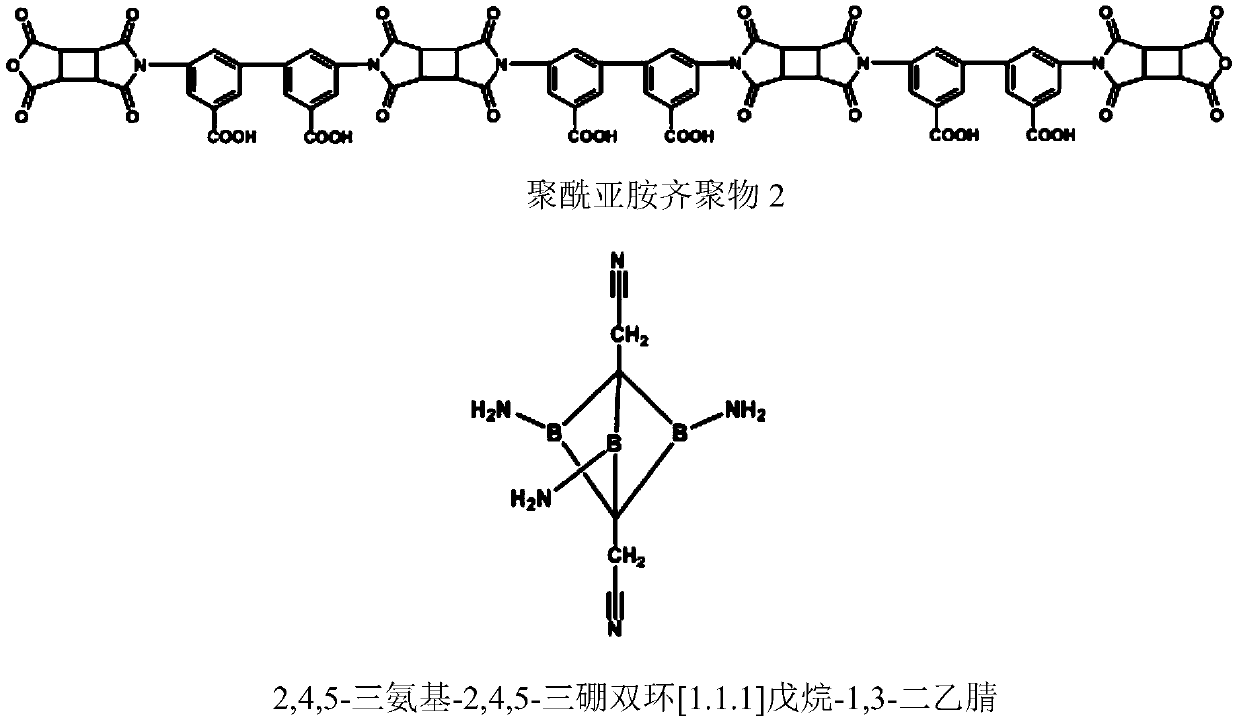

[0035] (1) Under nitrogen protection, in a three-necked flask, add 320mL of DMAc, 85.7g (0.057mol) of anhydride-terminated oligomer 2 (structural formula as follows, purity>99%), 7.0g (0.038mol) of 2,4,5-triamino-2,4,5-triboronbicyclo[1.1.1]pentane-1,3-diacetonitrile (structural formula is as follows, Aladdin reagent, analytically pure), stirred and reacted at 5°C for 15h ; Then the temperature was raised to 115°C, 135°C, and 165°C respectively for 1 hour, and finally the temperature was raised to 180°C for 22 hours of constant temperature reaction to obtain a hyperbranched polyimide solution with a solid content of 22%.

[0036]

[0037] (2) the hyperbranched polyimide solution (solid content 22%) that the silane coupling agent KH550 of 8g, the lithium bromide of 1g, 0.07g, 270g step (1) gained are placed in the planetary ball mill successively, Ball milling at 60° C. for 15 hours, and discharging, to obtain a functional anti-neutron radiation polyimide coating.

[0038] ...

Embodiment 3

[0040] (1) Under nitrogen protection, in a three-necked flask, add 350mL of NMP, 78.1g (0.05mol) of anhydride-terminated oligomer 3 (structural formula as follows, purity>99%), 6.2g (0.034mol) of 2,4,5-triamino-2,4,5-triboronbicyclo[1.1.1]pentane-1,3-diacetonitrile (structural formula is as follows, Aladdin reagent, analytically pure), stirred and reacted at 5°C for 17h ; Then the temperature was raised to 115°C, 135°C, and 165°C for 1 hour respectively, and finally the temperature was raised to 180°C for constant temperature reaction for 25 hours to obtain a hyperbranched polyimide solution with a solid content of 19%.

[0041]

[0042]

[0043] (2) with the gadolinium oxide of 12g, the boron carbide of 1.2g, the lithium fluoride of 0.5g successively, the hyperbranched polyimide solution (solid content 19% of the silane coupling agent KH550 of 0.08g, 310g step (1) gained %) placed in a planetary ball mill, ball milled at 65° C. for 17 hours, and discharged to obtain a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com