Wormwood micropowder composite acrylic fiber polymer material fiber and preparation method thereof

A technology of polymer materials and micropowder, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, and conjugated synthetic polymer rayon, etc. It can solve the problems of difficult control of grafting rate and low proportion of effective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

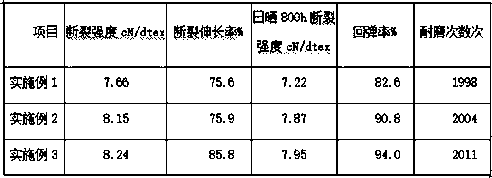

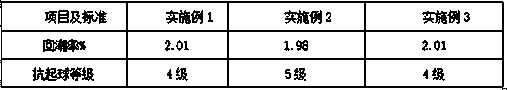

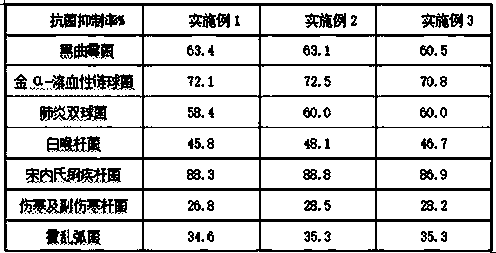

Examples

Embodiment 1

[0037] Embodiment 1 A kind of wormwood micropowder composite acrylic polymer material fiber and its preparation method

[0038] The present invention provides a method for preparing acrylic polymer fiber composited with wormwood micropowder, the method comprising: preparation of modified polyacrylonitrile spinning solution, preparation, blending and spinning of wormwood micropowder; specifically:

[0039] (1) Preparation of modified polyacrylonitrile spinning solution

[0040] Mix commercially available polyacrylonitrile P30T powder, ethanol and water-soluble polylactic acid multi-block polycarbonate, dissolve in solvent dimethylformamide to form modified polyacrylonitrile spinning solution;

[0041] The polyacrylonitrile P30T powder has a relative density of 1.12, a molecular weight Mw of 95000, and a moisture content of 0.01%;

[0042] The water-soluble polylactic acid multi-block polycarbonate has a weight average molecular weight of 59300-61000 (gel permeation chromatogra...

Embodiment 2

[0059] Embodiment 2 A kind of wormwood micropowder composite acrylic polymer material fiber and its preparation method

[0060] The present invention also provides a preparation method of wormwood micropowder composite acrylic polymer fiber, said method comprising: preparation of modified polyacrylonitrile spinning solution, preparation, blending and spinning of wormwood micropowder; specifically:

[0061] (1) Preparation of modified polyacrylonitrile spinning solution

[0062] Mix commercially available polyacrylonitrile P30T powder, ethanol and water-soluble polylactic acid multi-block polycarbonate, dissolve in solvent dimethylformamide to form modified polyacrylonitrile spinning solution;

[0063] The polyacrylonitrile P30T powder has a relative density of 1.12, a molecular weight Mw of 10000-11000, and a moisture content of ≤1%;

[0064] The water-soluble polylactic acid multi-block polycarbonate has a weight average molecular weight of 79800-81200 (gel permeation chroma...

Embodiment 3

[0081] Embodiment 3 A kind of wormwood micropowder composite acrylic polymer material fiber and its preparation method

[0082] The present invention also provides a preparation method of wormwood micropowder composite acrylic polymer fiber, said method comprising: preparation of modified polyacrylonitrile spinning solution, preparation, blending and spinning of wormwood micropowder; specifically:

[0083] (1) Preparation of modified polyacrylonitrile spinning solution

[0084] Mix commercially available polyacrylonitrile P30T powder, ethanol and water-soluble polylactic acid multi-block polycarbonate, dissolve in solvent dimethylformamide to form modified polyacrylonitrile spinning solution;

[0085] The polyacrylonitrile P30T powder has a relative density of 1.12, a molecular weight Mw of 98500-10000, and a moisture content of ≤1%;

[0086] The water-soluble polylactic acid multi-block polycarbonate has a weight average molecular weight of 66800-70700 (gel permeation chroma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com