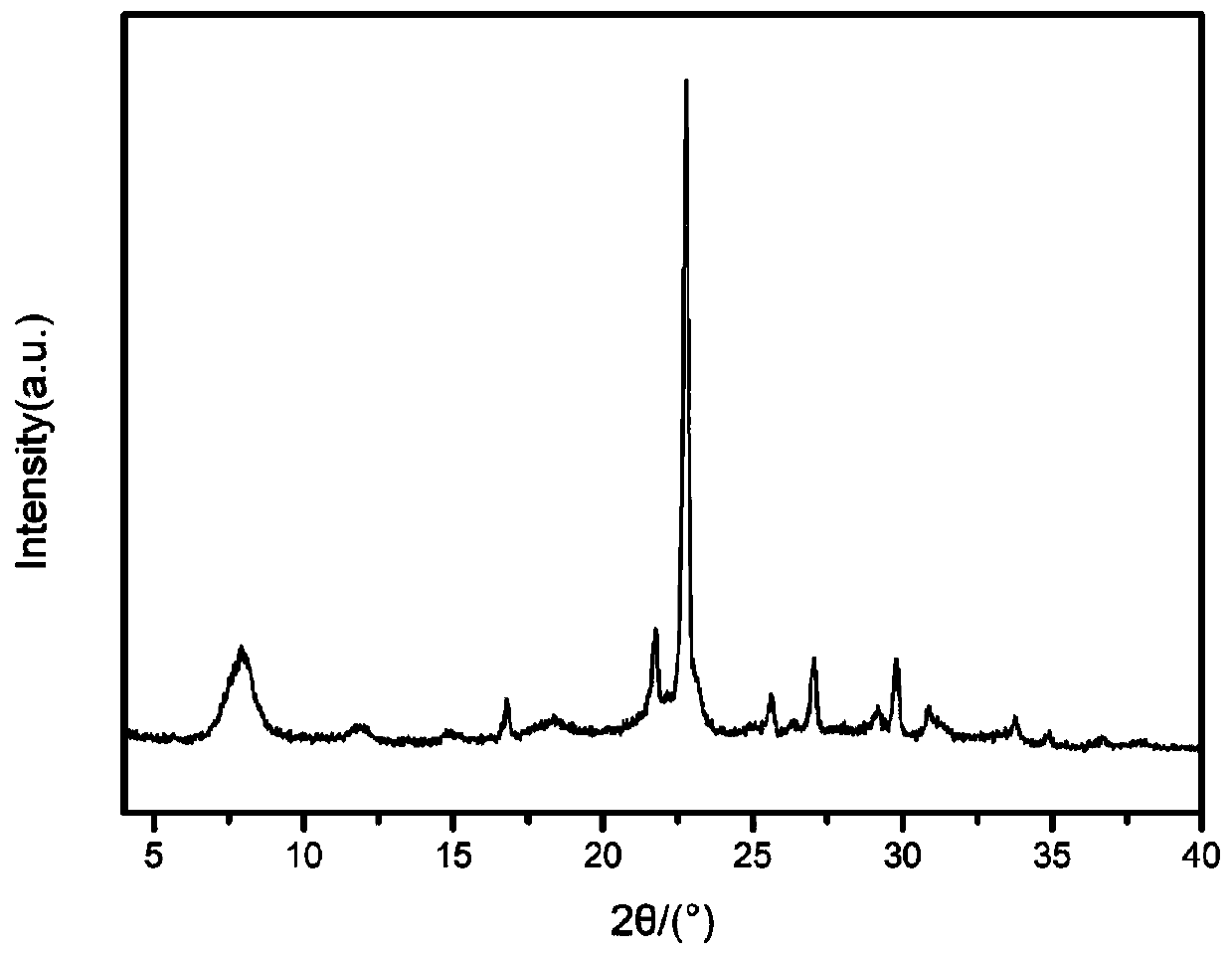

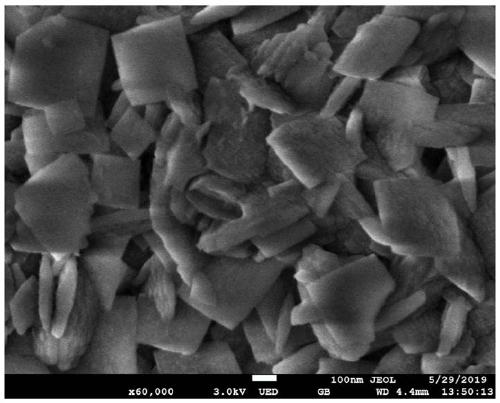

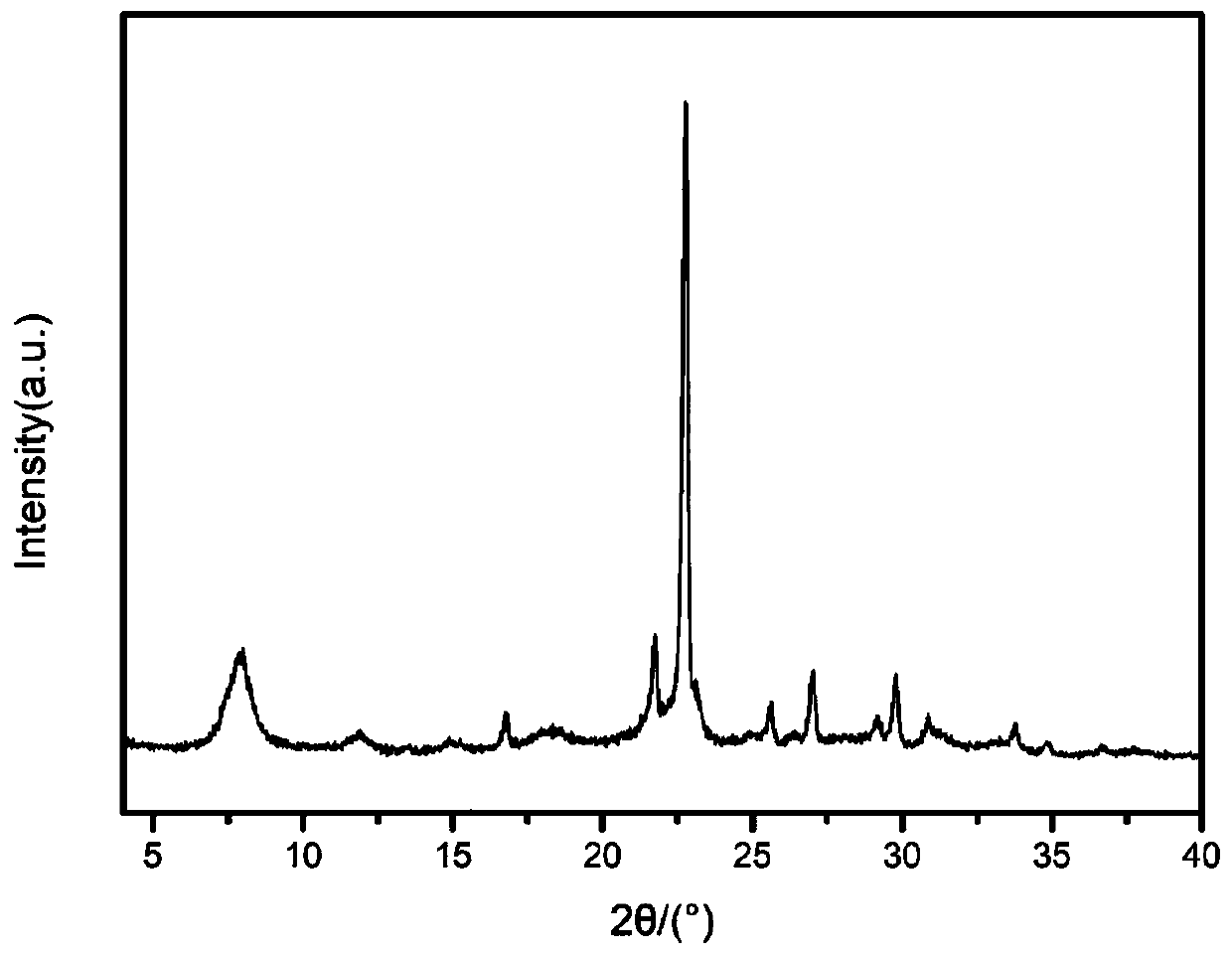

Method for synthesizing pure silicon Beta molecular sieves in hydrothermal and fluoride-free manner

A molecular sieve and pure silicon technology, applied in the field of zeolite molecular sieve preparation, can solve the problem of expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of seed crystals:

[0038] (1) 3.535 grams of tetraethylammonium hydroxide and 5 milliliters of distilled water are added to the reaction vessel, and stirred at room temperature until the two are evenly mixed;

[0039] (2) Add 4.5 grams of ethyl orthosilicate to the above solution under stirring, and continue stirring until the hydrolysis of ethyl orthosilicate is complete;

[0040] (3) Continue to stir until the moisture evaporates and becomes a dry gel, and the sample is ground into powder;

[0041] (4) Weigh 0.324 grams of ammonium fluoride, add it to the powder of step (3), and continue grinding until the two are evenly mixed; the silicon source is converted into SiO 2 For calculation, the active ingredient and molar ratio are SiO 2 :TEAOH:NH 4 F:H 2 O=100:40:40:100;

[0042] (5) crystallize the mixture obtained in step (4) at 150°C for 7 days;

[0043](6) After being cooled to room temperature, the obtained solid is washed with distilled water and...

Embodiment 1

[0048] (1) 0.421 gram of tetraethylammonium hydroxide solution and 5.4 milliliters of distilled water are added in the reaction vessel, stirred at room temperature until the two are evenly mixed;

[0049] (2) Add 1.929 grams of ethyl orthosilicate (wherein SiO 2 Quality is 0.54 gram), continue to stir until hydrolysis of ethyl orthosilicate is complete;

[0050] (3) Add 0.02 gram of sodium hydroxide to the above solution, and stir under airtight and room temperature conditions to form a uniform mixed solution;

[0051] (4) Add 0.027 gram of Beta molecular sieve seed crystals to the homogeneous mixed solution formed in step (3). Stir the gel at room temperature to the desired water-to-silicon ratio, converting the silicon source to SiO 2 For calculation, the active ingredients and molar ratio of the gel are SiO 2 :TEAOH:NaOH:H 2 O=90:10:5:1000, the input amount of seed crystal is to convert the silicon source used in step (2) into SiO 2 5% of the mass.

[0052] (5) hydrot...

Embodiment 2

[0056] (1) 0.631 gram of tetraethylammonium hydroxide solution and 5.4 milliliters of distilled water are added in the reaction vessel, and stirred at room temperature until the two are evenly mixed;

[0057] (2) Add 2.143 grams of ethyl orthosilicate (wherein SiO 2 Quality is 0.6 gram), continue to stir until hydrolysis of ethyl orthosilicate is complete;

[0058] (3) Add 0.008 gram of sodium hydroxide to above-mentioned solution, stir under airtight, room temperature condition to form uniform mixed solution;

[0059] (4) Add 0.03 gram of Beta molecular sieve seed crystals to the homogeneous mixed solution formed in step (3). Stir the gel at room temperature to the desired water-to-silicon ratio, converting the silicon source to SiO 2 For calculation, the active ingredients and molar ratio of the gel are SiO 2 :TEAOH:NaOH:H 2 O=100:15:2:1500, the input amount of seed crystal is to convert the silicon source used in step (2) into SiO 2 5% of the mass.

[0060] (5) hydrot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com