Hydrophobic pore-blocking ingredient emulsion and preparation method thereof

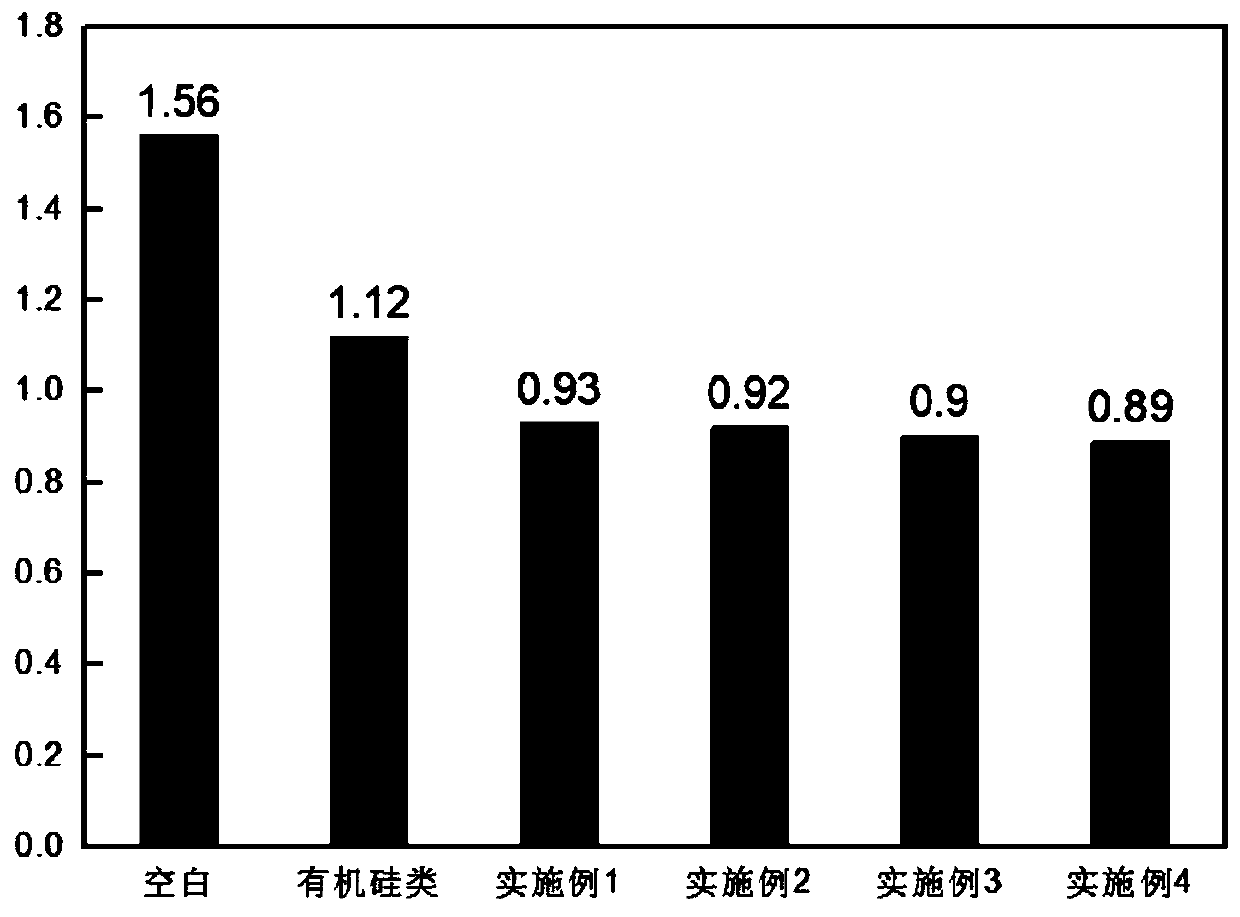

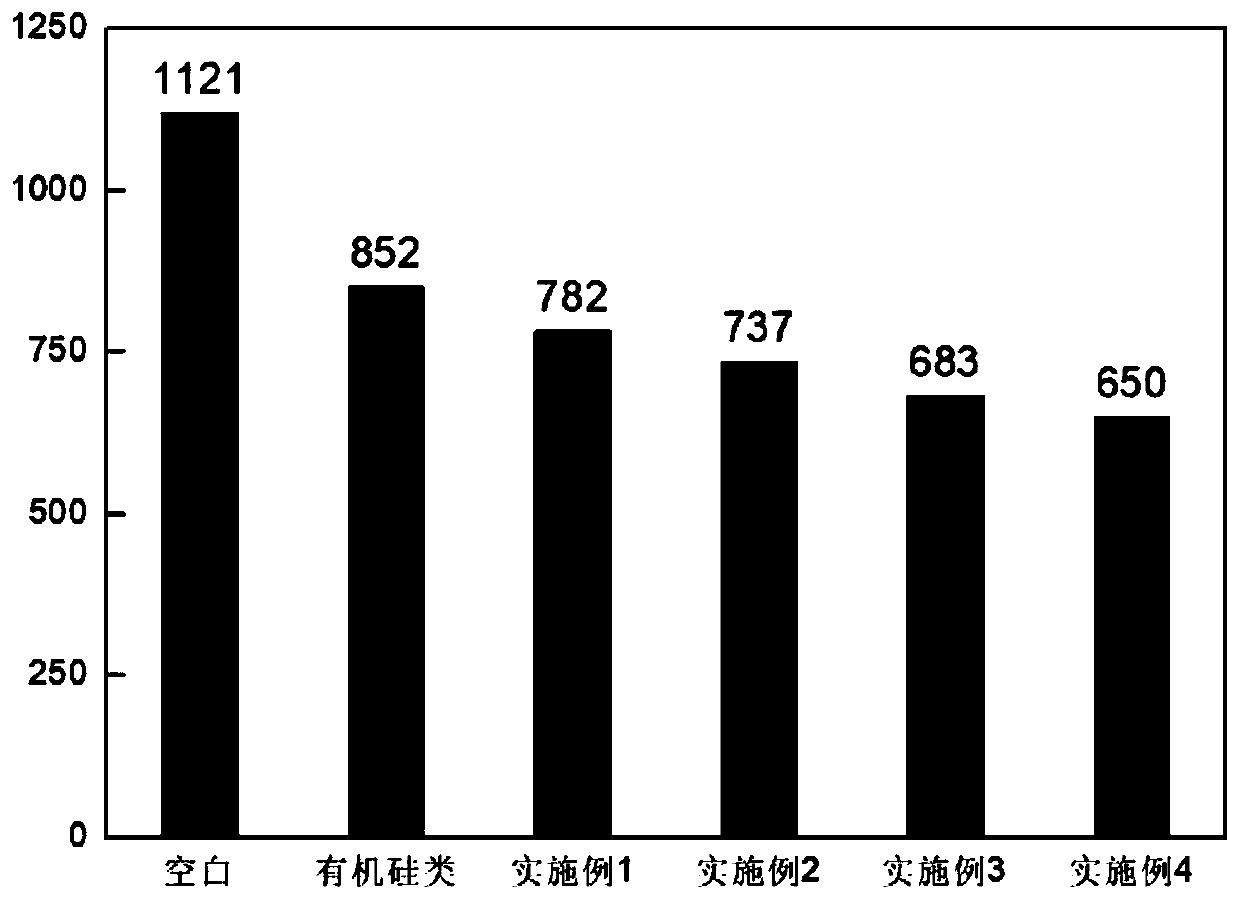

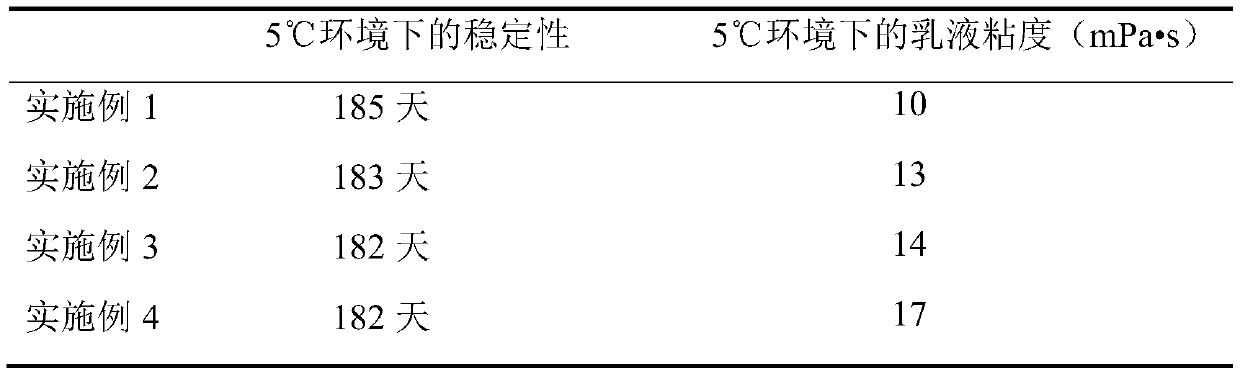

A hydrophobic and embolism technology, which is applied in the field of preparation of hydrophobic compound pore embolism emulsion, can solve the problems of poor defoaming effect of tiny bubbles, and achieve the effects of eliminating bubbles, low foaming, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A hydrophobic compound pore embolus emulsion, its composition and proportion are respectively: 10wt% of hardened oil, 15wt% of ammonia water, 0.1wt% of defoaming and antifoaming agent, 1wt% of emulsifier, and the balance is water; wherein, the The mass concentration of ammonia water is 15%.

[0029] The preparation method of the hydrophobic compound pore embolus emulsion provided in this example, the specific steps are as follows: put 60g of hardened oil in a three-necked flask and heat it to 90°C to dissolve it for 10 minutes. After dissolving, add a few drops of ammonia water and 443.4g of water, then quickly stir and disperse at 1100r / min at 90°C for 1h; then, add the remaining 90g of ammonia water, 6g of emulsifier and 0.6g of defoaming and antifoaming agent at 65°C and stir at a medium speed of 750r / min for 3h ; Finally, slow down to room temperature with 450r / min stirring to obtain a hydrophobic compound pore embolus emulsion.

Embodiment 2

[0031] A hydrophobic compound pore embolus emulsion, its composition and proportion are respectively: 11wt% of hardened oil, 18wt% of ammonia water, 0.15wt% of defoaming and antifoaming agent, 1.3wt% of emulsifier, and the balance is water; The stated ammonia mass concentration is 18%.

[0032] The preparation method of the hydrophobic compound pore embolus emulsion provided in this example, the specific steps are as follows: put 66g of hardened oil in a three-necked flask and heat it to dissolve at a temperature of 90°C. The heating time is 10min. After dissolving, add a few drops of ammonia water and 417.3g of water, then quickly stir and disperse at 1200r / min at 90°C for 1h; then, add the remaining 108g of ammonia water, 7.8g of emulsifier and 0.9g of defoaming and antifoaming agent and stir at 60°C at a medium speed of 900r / min for ammoniation 3h; finally, slowly stir at 300r / min and cool down to room temperature to obtain a hydrophobic compound pore embolus emulsion.

Embodiment 3

[0034] A hydrophobic compound pore embolus emulsion, its composition and proportion are respectively: 13wt% of hardened oil, 22wt% of ammonia water, 0.3wt% of defoaming and antifoaming agent, 1.7wt% of emulsifier, and the balance is water; The stated ammonia mass concentration is 22%.

[0035] The preparation method of the hydrophobic compound pore embolus emulsion provided in this example, the specific steps are as follows: put 78g of hardened oil in a three-necked flask and heat it to 90°C to dissolve it for 10 minutes. After dissolving, add a few drops of ammonia water and 378g of water, then stir and disperse rapidly at 90°C at 900r / min for 1h; then, add the remaining 132g of ammonia water, 10.2g of emulsifier and 1.8g of defoaming and antifoaming agent and stir at 65°C at a medium speed of 600r / min for 3h; Finally, stirring at a slow speed of 400 r / min and cooling down to room temperature to obtain a hydrophobic compound pore embolus emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com