Hyper-crosslinked resin and its application in adsorption separation of 5-hydroxymethylfurfural

A technology of ultra-high cross-linked resin and resin, applied in the direction of selective adsorption, ion exchange, ion exchange regeneration, etc., to achieve the effect of high adsorption selectivity, fast and efficient adsorption and separation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

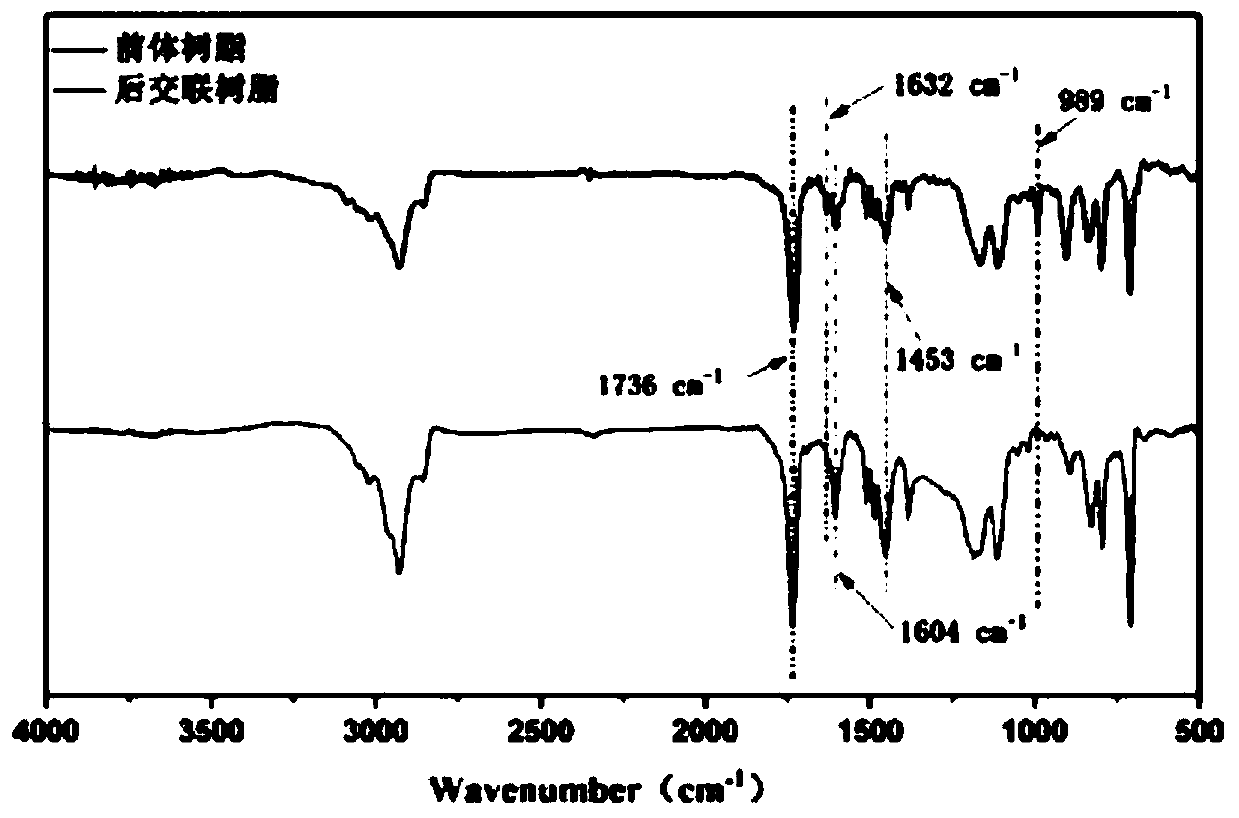

[0035] A kind of preparation method of ultra-high cross-linked resin is as follows:

[0036] (1) Preparation of precursor resin: Add 240g of the water phase into a 500mL three-necked flask, add the oil phase into the water phase, blow in nitrogen for 5 minutes, adjust the speed to 135rpm, raise the temperature to 80°C, keep it for 5h, and use hot water to finish the reaction 1. Rinse the resin in sequence with industrial alcohol until the washing solution is clear, then Soxhlet extraction for 48 hours, and then vacuum-dry at 45°C to constant weight to obtain the precursor resin;

[0037] Wherein the water phase contains 0.5% polyvinyl alcohol and 1% methylene blue, and the oil phase consists of ethylene glycol dimethacrylate 8g, divinylbenzene 32g, porogen toluene 24g and n-heptane 16g, initiator benzyl peroxide Acyl 0.4g;

[0038] (2) Preparation of post-crosslinked resin: add 120mL 1,2-dichloroethane to 10g precursor resin in (1) and soak overnight, then add 0.3g FeCl 3Cat...

Embodiment 2

[0044] The preparation method of the ultra-high cross-linked adsorption resin provided in this embodiment is the same as in Example 1, except that the amount of the dispersant polyvinyl alcohol in the water phase in step (1) is 0.25%, and the amount of the monomer in the oil phase is 0.25%. The mass is 20g, and the mass of the crosslinking agent is 20g.

[0045] The procedure for adsorbing 5-hydroxymethylfurfural by the ultra-highly cross-linked adsorption resin provided in this example is the same as that in Example 1.

Embodiment 3

[0047] The preparation method of the ultra-high cross-linked adsorption resin provided in this example is the same as in Example 1, except that the ester monomer in step (1) is ethylene glycol diacrylate.

[0048] The procedure for adsorbing 5-hydroxymethylfurfural by the ultra-highly cross-linked adsorption resin provided in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com