Super-critical extraction method and applications of poplar bark lipid

A poplar bark lipoid and supercritical technology, which is applied in the production of fat, pharmaceutical formula, fat oil/fat production, etc., can solve the problems of oil oxidative rancidity, low yield, complicated pressing process, etc., and achieve low cost and no Solvent residue, simple effect of supercritical extraction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of poplar bark lipids

[0043]A. Selection of raw materials: Fresh poplar bark should be selected, and bark and magazines of other tree species should not be mixed. For mixing, sun-dried or moldy poplar bark is not allowed.

[0044] B. Pretreatment: Put poplar bark on the selection table to remove impurities and ash, put it into the washing machine, and repeatedly wash until the medicinal materials are free of sediment and soil, and the water quality of the outlet pipe is clear before taking out the raw materials. Place the washed poplar bark in a cool, clean place to dry until the surface of the bark is free of moisture. Use a medicine cutter to cut the poplar bark into small pieces, with a particle size of 50-60mm. Then, the cut poplar bark is placed in a stainless steel tray, flattened, and sent to an oven for drying. The oven temperature is set to 80°C, the drying time is 5-6 hours, and the moisture content is 12-15%. Use a pulverizer to pulverize...

Embodiment 2

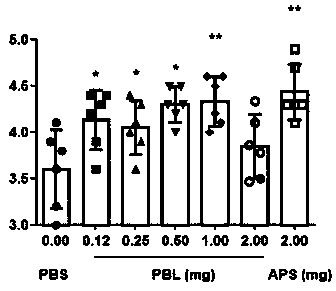

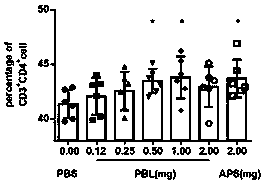

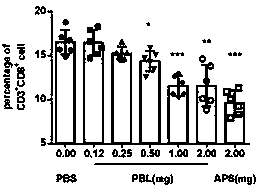

[0053] Detection of the immune-enhancing effect of the obtained poplar bark lipids

[0054] (1) Animals and administration: The experimental animals were 5-week-old female BALB / C mice (18-22 g), purchased from Jinan Pengyue Experimental Animal Breeding Co., Ltd. Care and use guidelines for handling. Animals were bred and maintained under standard laboratory conditions: temperature (25 ± 2 °C) and photoperiod of 12 h, food and water ad libitum. Animals were randomly divided into 7 groups, each group consisted of 6 animals, namely poplar bark lipid group, positive control group and blank control group. Poplar bark lipid (PBL) groups were given different concentrations of poplar bark lipids according to 0.12mg / day, 0.25mg / day, 0.50mg / day, 1.00mg / day and 2.00mg / day, and the positive control was given astragalus polysaccharide (APS) 2.00 mg / day, the blank control group was given the same amount of PBS. Gavage once a day for 28 consecutive days.

[0055] (2) Spleen index: 24 hou...

Embodiment 3

[0058] The effects of PBL on the production of inflammatory and anti-inflammatory factors in RAW264.7 cells stimulated by LPS were detected by enzyme-linked immunosorbent assay (ELISA).

[0059] The experiment was divided into control group (Con), LPS group (LPS), experimental group (different doses of PBL: 0.25, 0.5, 2 and 1 mg / ml), and each group was repeated three times. The RAW264.7 cell suspension with a density of 2 × 105 cells / ml was added to a 24-well plate, 0.5 ml per well, and cultured in a 37°C, 5% CO2 incubator. 24 hours after inoculation, PBL was added to the experimental group to make the final concentration of 0.25, 0.5, 1 and 2 mg / ml, and the same volume of DMEM medium was added to the Con group and LPS group, and cultured in a 37°C, 5% CO2 incubator. After 24 hours of treatment, the LPS group and the experimental group were added with LPS (final concentration of 1 mg / ml), and the cell supernatant was collected after 6 hours of treatment. The contents of IL-4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com