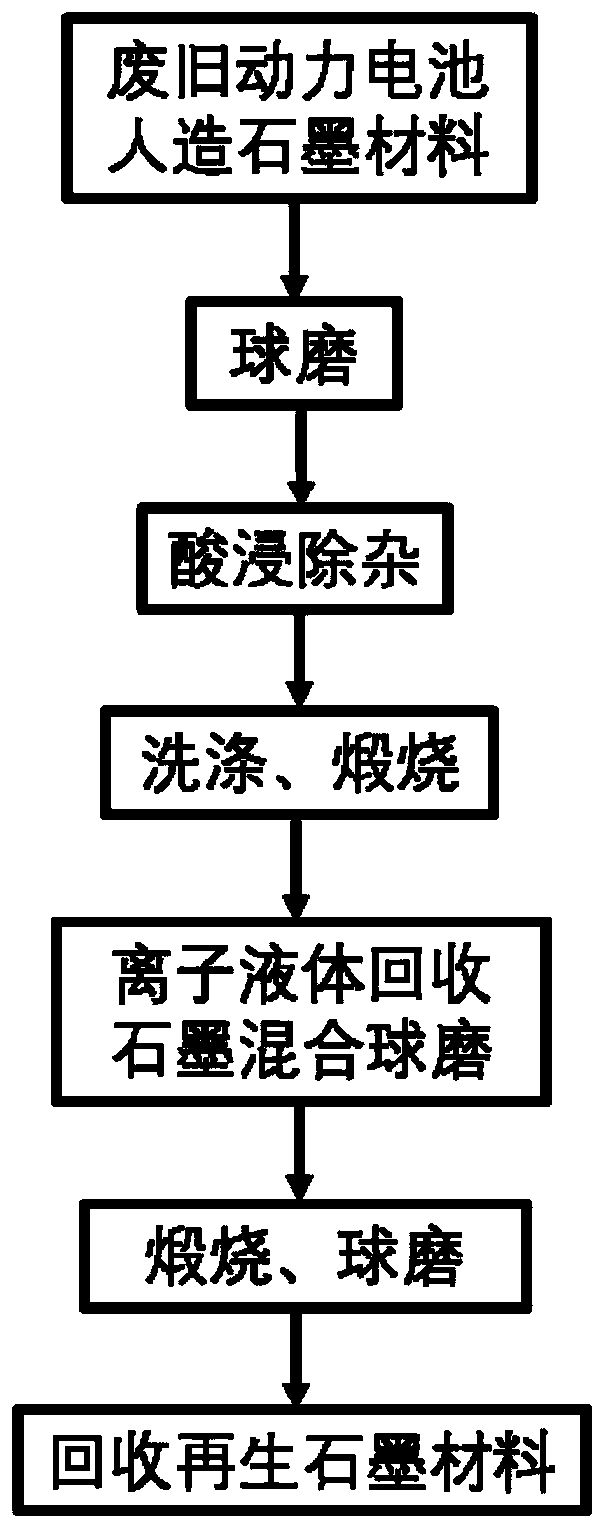

Regeneration method of ionic liquid coated waste power battery artificial graphite material

A technology for ionic liquids and power batteries, which is applied in the field of regeneration of artificial graphite materials coated with ionic liquids in waste power batteries, and can solve problems such as cycle stability and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 5 grams of recycled artificial graphite powder. After ball milling at 400r / min for 3 hours, disperse in 3mol / L nitric acid solution, heat and stir at 80°C for 2 hours, filter and wash. Dry in a vacuum oven at 60°C overnight. The dried material was mixed with 10 grams of 1-ethyl-3-methylimidazole bis-trifluoromethanesulfonimide ionic liquid, and ball milled at 300 rap / min for 5 hours. Calcined at 650° C. for 3 hours under an argon atmosphere. A regenerated artificial graphite negative electrode doped with regenerated ionic liquid and coated with ultrathin carbon is obtained.

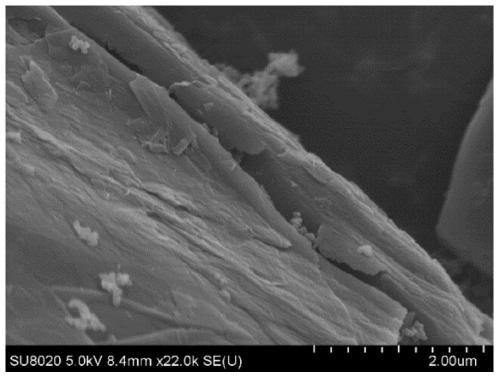

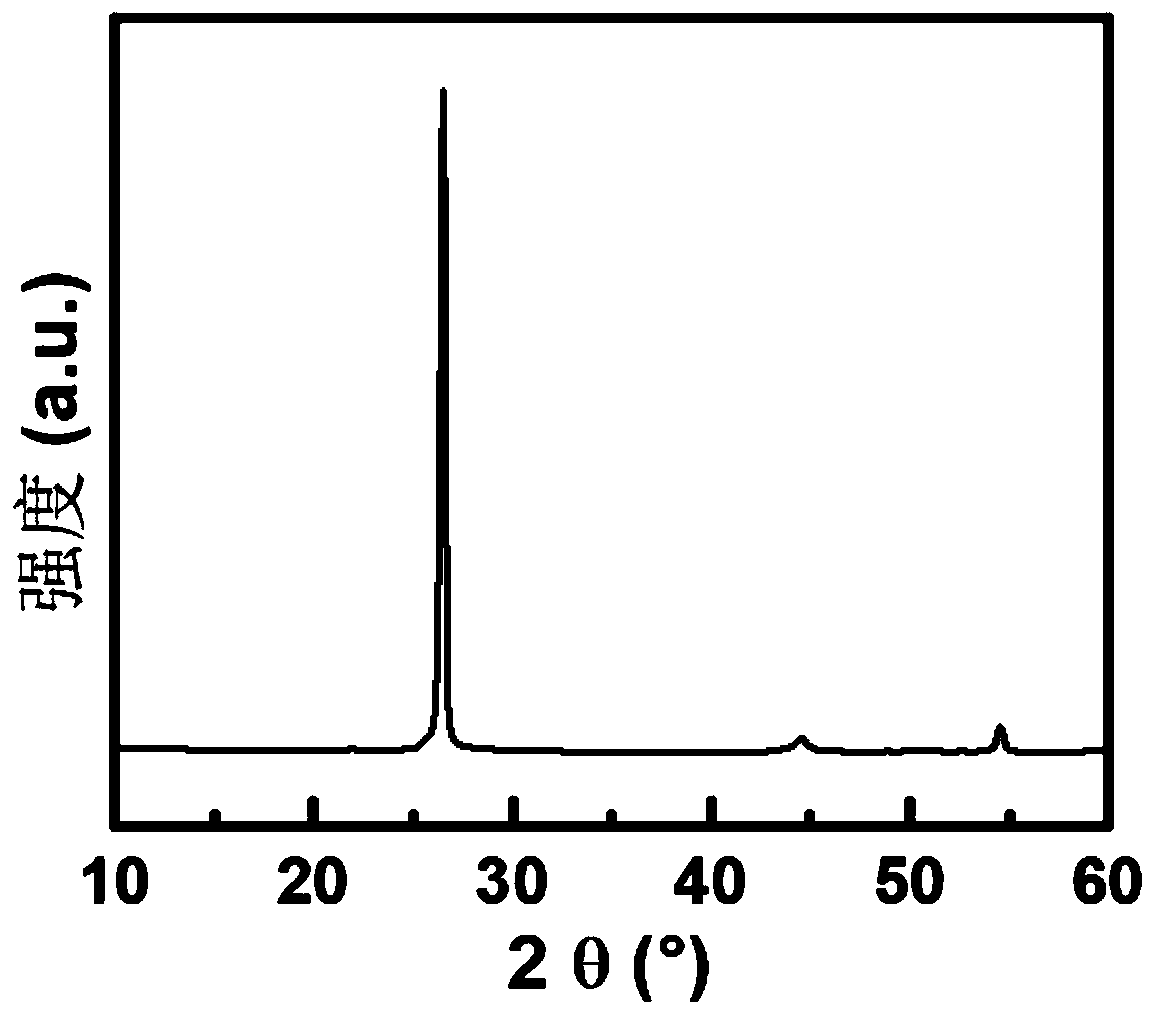

[0024] Further analysis of the regenerated graphite samples by electron microscopy revealed that the surface of the material is smooth and free of impurities, and at the same time the surface is covered with a coated carbon layer to achieve carbon coating. X-ray diffraction (XRD) test obtained pattern is consistent with commercial artificial graphite, without impurity peak, shows that sampl...

Embodiment 2

[0026] Take 5 grams of recycled artificial graphite powder. After ball milling at 300r / min for 4 hours, disperse in 3mol / L hydrochloric acid solution, heat and stir at 60°C for 3 hours, filter and wash. Dry in a vacuum oven at 60°C overnight. The dried material was mixed with 3 grams of 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid, and ball milled at 400 rap / min for 5 hours. Calcined at 600° C. for 2.5 hours under a helium atmosphere. Obtain the regenerated artificial graphite negative electrode doped with regenerated ionic liquid and coated with ultra-thin carbon.

Embodiment 3

[0028] Take 5 grams of recycled artificial graphite powder. After ball milling at 450r / min for 2 hours, disperse in 3mol / L sulfuric acid solution, heat and stir at 70°C for 3 hours, filter and wash. Dry in a vacuum oven at 60°C overnight. The dried material was mixed with 7 grams of 1-propyl-3-methylimidazole bis-trifluoromethanesulfonamide ionic liquid, and ball milled at 450 rap / min for 5 hours. Calcined at 550° C. for 4 hours under nitrogen atmosphere. A regenerated artificial graphite negative electrode doped with ultrathin carbon coated with regenerated ionic liquid is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com