Composite platinum nanoparticle and metal nitride material catalyst and preparation method and application thereof

A technology of platinum nanoparticles and nitrides, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as unfavorable industrial mass production, phenolic compound polymerization, catalyst deactivation, etc. Achieve the effect of low cost, mild conditions and high conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

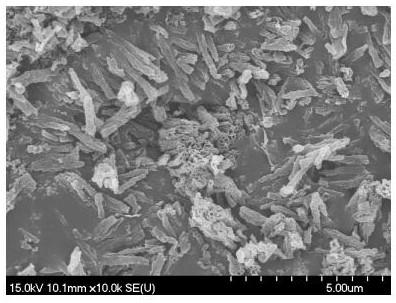

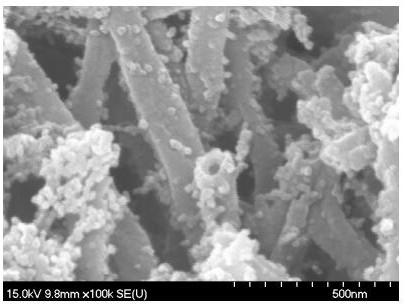

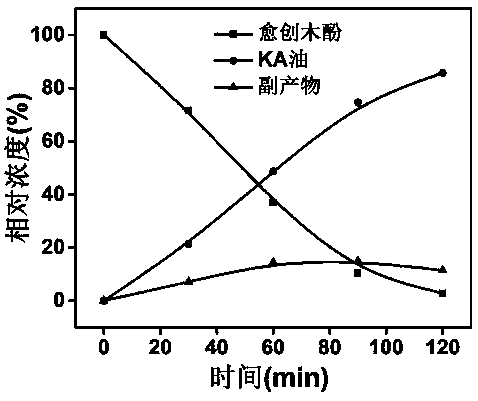

[0033] Example 1: Synthesis of Pt / CoN@BCN catalyst and its electrocatalytic reduction of guaiacol to prepare KA oil and its derivatives

[0034] (1) Dissolve 0.15 g of boric acid, 5 g of urea, and 0.5 g of polyethylene glycol into 50 mL of water and disperse uniformly by ultrasonic, then add 0.065 g of cobalt phthalocyanine, stir at room temperature for 1 hour, and then transfer the obtained solution to an oven , dried at 120°C for 14 hours to obtain a solid mixture;

[0035] (2) Place the solid mixture obtained in step (1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under an argon atmosphere, and calcinate at 900°C for 4 hours to obtain a catalyst carrier (The catalyst support is marked as CoNx@BCN);

[0036] (3) Take 20 mg of the catalyst carrier CoNx@BCN obtained in step (2) and 5 mg of chloroplatinic acid into 10 mL of deionized water, and ultrasonically mix the solution for 1 hour to obtain a solution A; dissolve 8 mg of sod...

Embodiment 2

[0042] Example 2: Synthesis of Pt / FeNx@BCN catalyst and its electrocatalytic reduction of guaiacol to prepare KA oil and its derivatives

[0043] (1) Dissolve 0.15 g of boric acid, 5 g of urea, and 0.5 g of polyethylene glycol into 50 mL of water for ultrasonic dispersion, then add 0.060 g of iron phthalocyanine, stir at room temperature for 1 hour, and then transfer the resulting solution to an oven , dried at 100°C for 12 hours to obtain a solid mixture;

[0044] (2) Place the solid mixture obtained in step (1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under an argon atmosphere, and calcinate at 900°C for 4 hours to obtain a catalyst carrier (The catalyst support is marked as FeNx@BCN);

[0045] (3) Take 20 mg of the catalyst carrier FeNx@BCN obtained in step (2) and 5 mg of chloroplatinic acid into 10 mL of deionized water, and ultrasonically mix the solution for 1 hour to obtain A solution; dissolve 8 mg of sodium borohyd...

Embodiment 3

[0050] Example 3: Synthesis of Pt / NiNx@BCN catalyst and its electrocatalytic reduction of guaiacol to prepare KA oil and its derivatives

[0051] (1) Dissolve 0.15 g of boric acid, 5 g of urea, and 0.5 g of polyethylene glycol in 50 mL of water and disperse uniformly by ultrasonication, then add 0.068 g of nickel phthalocyanine, stir at room temperature for 1 hour, and then transfer the obtained solution to In an oven, dry at 100°C for 8 hours to obtain a solid mixture;

[0052] (2) Place the solid mixture obtained in step (1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under an argon atmosphere, and calcinate at 900°C for 4 hours to obtain a catalyst carrier (The catalyst support is marked as NiNx@BCN);

[0053] (3) Take 20 mg of the catalyst carrier NiNx@BCN obtained in step (2) and 5 mg of chloroplatinic acid into 10 mL of deionized water, and ultrasonically mix the solution for 1 hour to obtain A solution; dissolve 8 mg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com