Composite aqueous solution containing heparin sodium enzymolysis waste liquid and vitamins

A technology of heparin sodium enzyme and vitamins, which is applied in the field of composite aqueous solutions containing heparin sodium enzymolysis waste liquid and vitamins, can solve the problem of not preparing a composite aqueous solution containing heparin sodium enzymolysis waste liquid, etc., to ensure rapid growth and low cost , the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

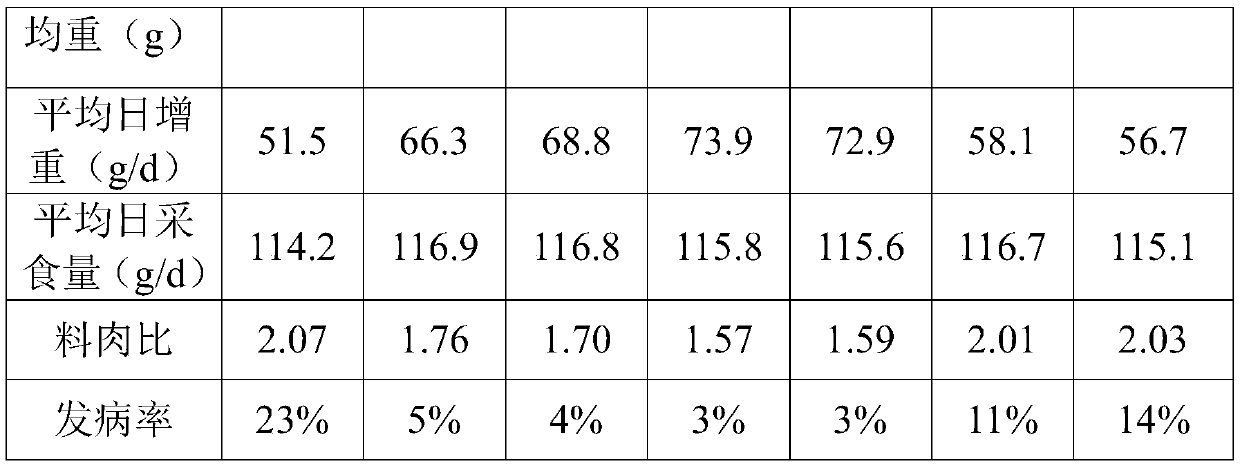

Examples

Embodiment 1

[0029] This example provides a composite aqueous solution containing heparin sodium enzymolysis waste liquid and vitamins, which is prepared by the following method:

[0030] S1: Weigh the following fat-soluble vitamins: vitamin A oil (1 million IU / g) 5g, vitamin D 3 Oil (1 million IU / g) 2g, vitamin E oil 3g, vitamin K 3 0.5g, then the above-mentioned fat-soluble vitamins, lecithin 10g, and ethanol 5g were stirred and mixed evenly to obtain an oil phase;

[0031] S2: Weigh the following water-soluble vitamins: vitamin B 1 2g, vitamin B 2 1g, vitamin B 6 1g, vitamin B 12 3mg, 3g of vitamin C, 5g of nicotinamide, and then add the above-mentioned water-soluble vitamins, 5g of calcium pantothenate, 5g of inositol, and 1g of sodium benzoate into 300mL of heparin sodium enzymolysis waste liquid and stir to dissolve, so as to obtain an aqueous phase;

[0032] S3: add the water phase to the oil phase, and grind and mix evenly through a colloid mill to obtain a mixed solution...

Embodiment 2

[0035] This example provides a composite aqueous solution containing heparin sodium enzymolysis waste liquid and vitamins, which is prepared by the following method:

[0036] S1: Weigh the following fat-soluble vitamins: vitamin A oil (1 million IU / g) 20g, vitamin D 3 Oil (1 million IU / g) 5g, vitamin E oil 10g, vitamin K 3 1g, then the above-mentioned fat-soluble vitamins, Tween80 10g, Span8010g, 1,2-propanediol 5g, glycerin 5g, stirred and mixed evenly to obtain an oil phase;

[0037] S2: Weigh the following water-soluble vitamins: vitamin B 1 3g, vitamin B 2 3g, vitamin B 6 3g, vitamin B 12 10mg, vitamin C10g, nicotinamide 10g, and then the above water-soluble vitamins, calcium pantothenate 10g, inositol 5g, sodium benzoate 1g, potassium sorbate 1g, add 400mL heparin sodium enzymolysis waste liquid and stir to dissolve to prepare the aqueous phase;

[0038] S3: add the water phase to the oil phase, and grind and mix evenly through a colloid mill to obtain a mixed s...

Embodiment 3

[0041] This example provides a composite aqueous solution containing heparin sodium enzymolysis waste liquid and vitamins, which is prepared by the following method:

[0042] S1: Weigh the following fat-soluble vitamins: vitamin A oil (1 million IU / g) 30g, vitamin D 3 Oil (1 million IU / g) 10g, vitamin E oil 20g, vitamin K 3 5g, then the above-mentioned fat-soluble vitamins, lecithin 20g, soybean lecithin 20g, ethanol 5g, glycerol 15g, stir and mix, and make the oil phase;

[0043] S2: Weigh the following water-soluble vitamins: vitamin B 1 5g, vitamin B 2 5g, vitamin B 6 5g, vitamin B 1220mg, 20g of vitamin C, 20g of nicotinamide, and then add 500mL of heparin sodium enzymolysis waste liquid and stir to dissolve the above-mentioned water-soluble vitamins, 20g of calcium pantothenate, 2g of sodium benzoate, and 2g of potassium sorbate, and stir to obtain an aqueous phase;

[0044] S3: add the water phase to the oil phase, and grind and mix evenly through a colloid mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com