Water-soluble polymer gel polymer electrolyte, preparation method thereof and application thereof

A water-soluble polymer and water-soluble polymer technology, applied in the field of electrochemical energy storage, can solve the problems of environmental pollution, complex preparation process, high cost, etc., and achieve the effects of avoiding environmental pollution, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] (1) Mix sodium carboxymethyl cellulose (CMC), lithium lanthanum zirconium oxygen solid electrolyte and water at a ratio of 1 / 1 / 200 (w / w / w), stir at room temperature for 6 hours to obtain a dispersed aqueous solution.

[0051] (2) Pour the aqueous solution into a storage container of a freeze dryer, freeze-dry at a cold trap temperature of -60° C. and a vacuum of 10 Pa.

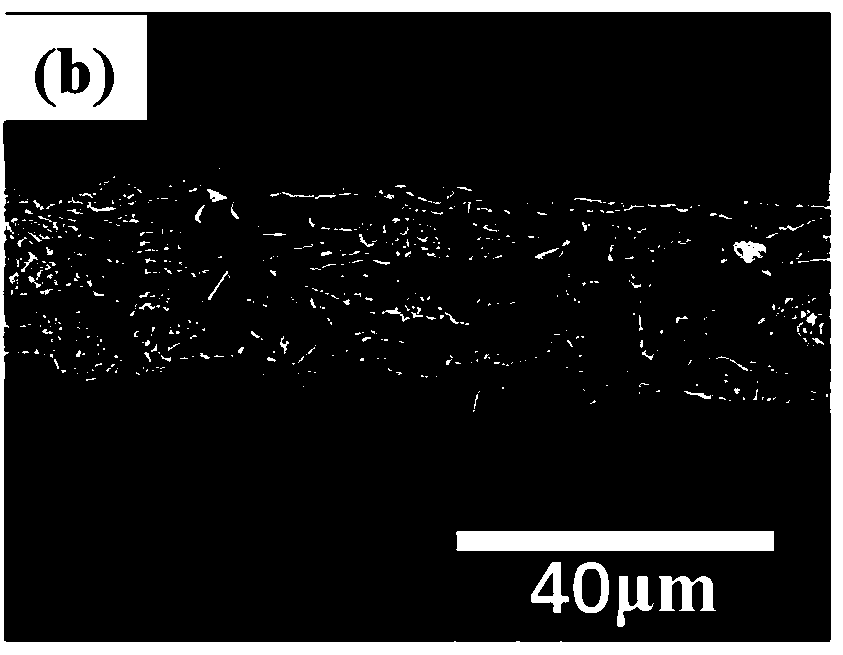

[0052] (3) The dried product was rolled by heating at 80° C. for 50 times to obtain a polymer film of 35 μm.

[0053] (4) After the prepared electrolyte membrane was cut into an appropriate size, it was placed in a vacuum drying oven, dried at 80°C for 24 hours to remove traces of water, cooled to room temperature under vacuum, and transferred into a glove box for storage. Soak it in 1molL -1 LiPF 6 Carboxymethylcellulose gel polymer electrolyte (CMC-GPE) was obtained in electrolyte solution (purchased from Zhangjiagang Guotai Huarong New Material Co., Ltd.) for 12 hours.

Embodiment 3

[0055] (1) Mix polyvinyl alcohol (PVA) and polyethylene oxide (PEO) with water at a ratio of 1 / 1 / 100 (w / w / w), and stir at room temperature for 6 hours to obtain a clear and uniform solution .

[0056] (2) Pour the aqueous solution into a storage container of a freeze dryer, freeze-dry at a cold trap temperature of -60° C. and a vacuum of 10 Pa.

[0057] (3) The dried product was heated and rolled at 60° C. for 30 times and 50 times to obtain a polymer film of 20 μm.

[0058] (4) After the prepared electrolyte membrane was cut into an appropriate size, it was placed in a vacuum drying oven, dried at 80°C for 24 hours to remove traces of water, cooled to room temperature under vacuum, and transferred into a glove box for storage. Soak it in 1molL -1 Polyvinyl alcohol-polyethylene oxide gel polymer electrolyte (PVA-PEO-GPE) was obtained in LiTFSI electrolyte (purchased from Zhangjiagang Guotai Huarong New Material Co., Ltd.) for 12 hours.

[0059] (5) Activated carbon is used ...

Embodiment 1

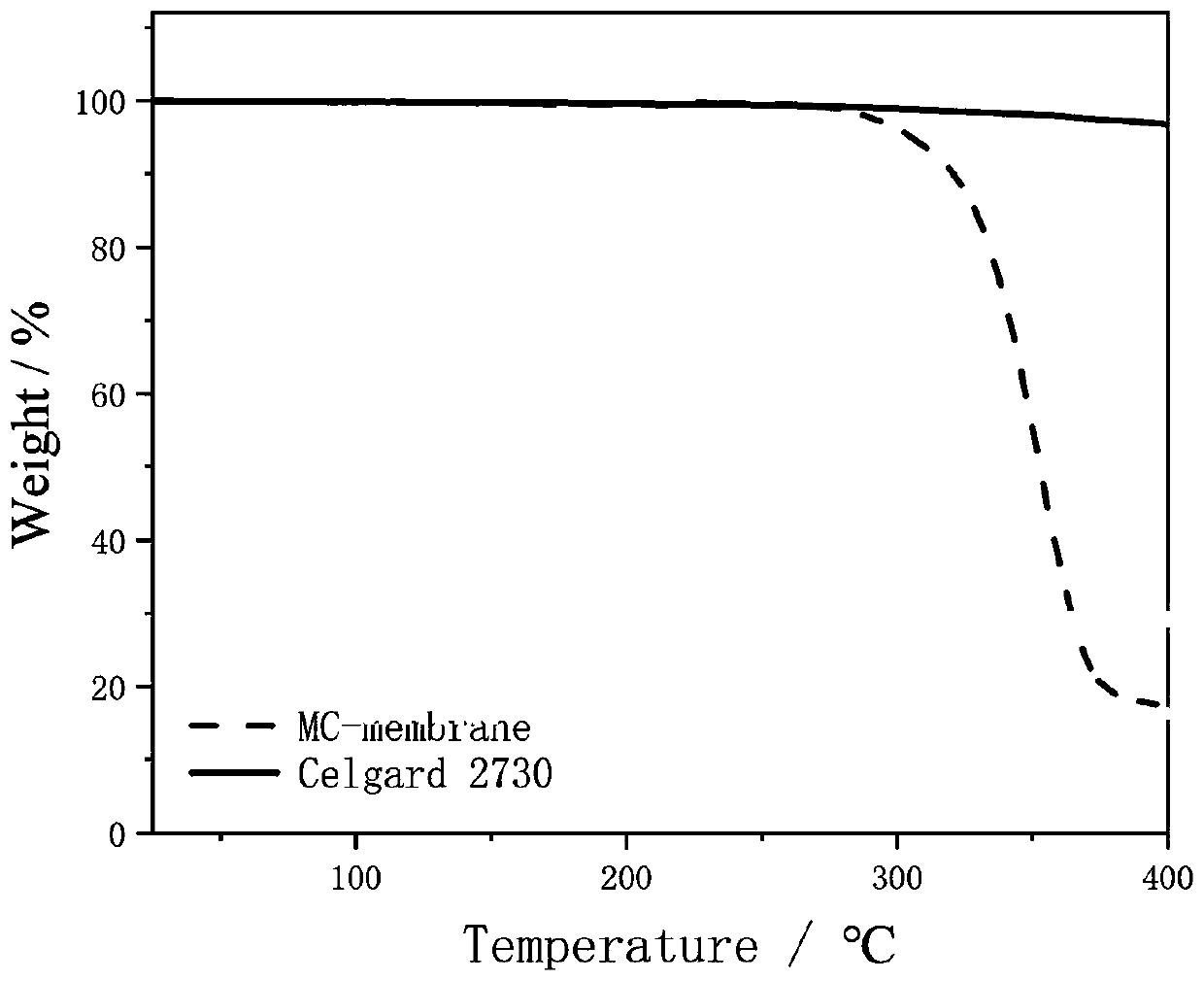

[0070] where, σ is the electrical conductivity, l is the thickness of the film, R b and A are the resistance of the membrane and the area of the electrode, respectively. The room temperature conductivity of the method of embodiment 1 obtained methyl cellulose gel membrane (MC-GPE) is 0.7mS cm -1 , the conductivity of the Celgard 2730 separator in the comparative example is 0.43mS cm -1。

[0071] The lithium ion migration number is calculated by formula (4):

[0072] t Li + = I SS / I 0 (4)

[0073] Among them, I 0 and I SS are the initial state current value and steady state current value obtained by the chronoflow method, respectively. The lithium ion migration number of the methylcellulose gel membrane (MC-GPE) obtained by the method in Example 1 was 0.48, and the lithium ion migration number of the Celgard 2730 diaphragm in the comparative example was 0.27.

[0074] From the comparison of the examples and the comparative examples, the gel polymer electrolyte ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com