Amino porous material and preparation method and application thereof

A porous material and amino technology, applied in the field of amino porous materials and its preparation, can solve the problems of a large number of oil droplets, pollution and consumption, and achieve the effects of fast adsorption rate, reduced water flux, and stable chemical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]

[0036] The preparation method of amino porous material of the present invention comprises the following steps:

[0037] Put the hydrophilic rigid material in the container, compact it, and pour the polyethyleneimine solution into the container, so that the rigid material components are wetted and the gaps between the solids are filled with the polyethyleneimine solution components. Stir properly at the same time to fully discharge the air and fully wet the solid, then add the crosslinking agent solution and stir to mix evenly, heat and dehydrate with a vacuum water pump to volatilize the water in the gaps between the rigid material components, and make 90% of the system The above water is released, and the polyethyleneimine and the crosslinking agent are fully crosslinked on the surface of the rigid material to form a net-like sleeve on the solid surface, thereby forming a firm surface functional adsorption layer, that is, an amino porous material is obtained.

[00...

Embodiment 1

[0062] The preparation method of the amino porous material of this embodiment includes the following steps:

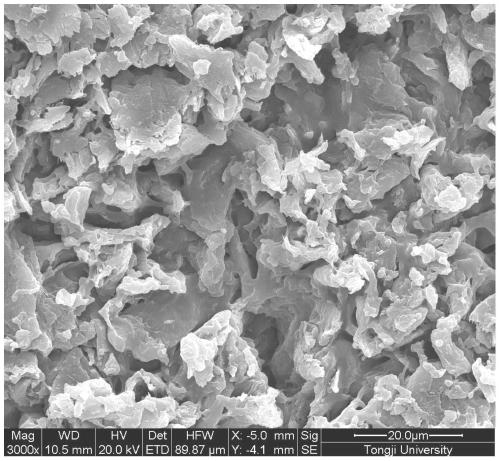

[0063] (1), microcrystalline cellulose (1.8g, particle size is 80μm) is added to branched polyethyleneimine (M n =60000, 0.05g / mL, 6mL) in the aqueous solution, stir, disperse, adjust the pH value to 11, add the water (1.5mL) solution of polyethylene glycol diglyceryl ether (molecular weight 2000, 1.44g), stir rapidly for 5min ; Stand still for 6 hours, vacuum dehydration with a water pump at 90°C, stop when the dehydration amount reaches 6.4g, and obtain an amino porous material, which is stored in a nitrogen environment, and its scanning electron microscope is as follows: figure 1 shown. The compression modulus tested by the electronic press is 31.6MPa, which is much higher than that of conventional plastic-based porous materials (typical value 3-6MPa), so its mechanical strength is high.

Embodiment 2

[0065] Same as Example 1, but using quartz sand (2.8g) instead of microcrystalline cellulose, the amino porous material was similarly obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com