Catalyst, preparation method thereof, and n-hexylamine production process using catalyst

A production process and catalyst technology, which is applied in the field of n-hexylamine production, can solve the problems of poor selectivity, low conversion rate and high reaction conditions, and achieve the effects of high conversion rate, corrosion avoidance and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

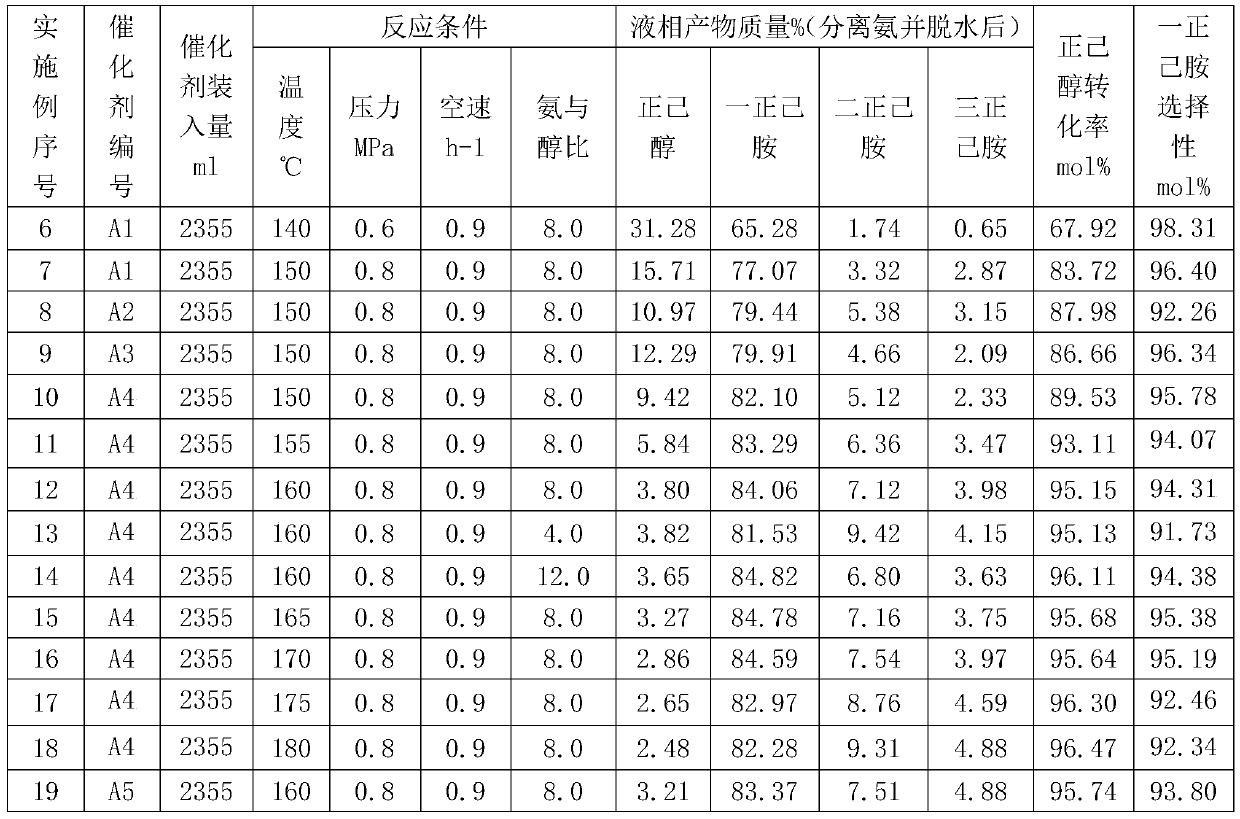

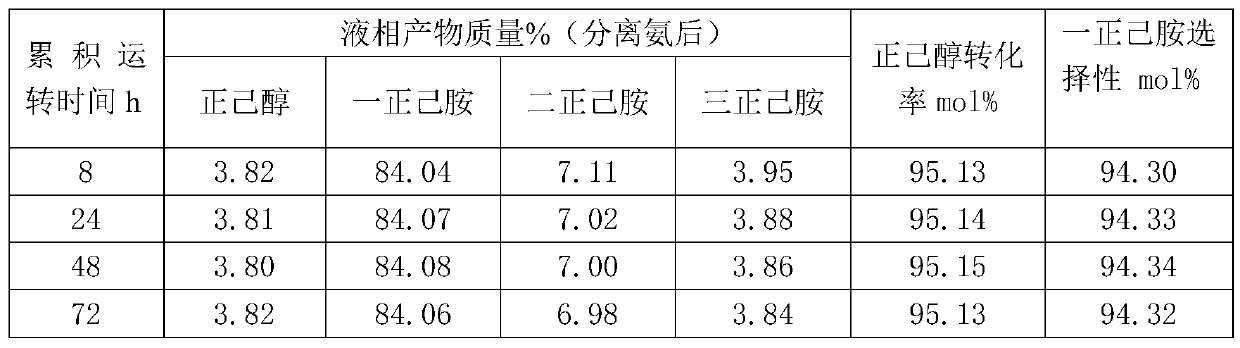

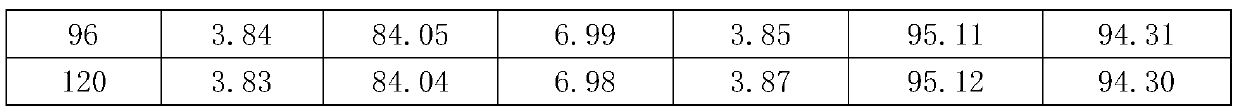

Examples

Embodiment 1

[0019] A kind of catalyst, described catalyst is Co-Zn / Al 2 o 3 , including the following components by weight: Co is 10.0%, Zn is 20.0%, and the rest is Al 2 o 3 .

[0020] A preparation method of catalyst, comprising the steps of: Al(OH) 3 Prepare a sodium metaaluminate solution with 40% NaOH, neutralize the precipitate with nitric acid, age, filter, wash, and roll into balls, dry, and roast to obtain spherical Al with a diameter of 1-3mm. 2 o 3 Carrier, the nitrate of Co and Zn is made into a mixed solution in proportion, for Al 2 o 3 The carrier is impregnated, dried and placed in a muffle furnace for calcination at 490°C for 6 hours. After cooling, it is impregnated with a mixed solution of Co and Zn nitrates again, and the catalyst is calcined under the same conditions. The bulk density of the catalyst was 0.90 g / ml. The catalyst number is A-1.

Embodiment 2

[0022] A kind of catalyst, described catalyst is Co-Zn / Al 2 o 3 , including the following components by weight: Co is 15.0%, Zn is 20.0%, and the rest is Al 2 o 3 .

[0023] A preparation method of catalyst, comprising the steps of: Al(OH) 3 Prepare a sodium metaaluminate solution with 40% NaOH, neutralize the precipitate with nitric acid, age, filter, wash, and roll into balls, dry, and roast to obtain spherical Al with a diameter of 1-3mm. 2 o 3 Carrier, the nitrate of Co and Zn is made into a mixed solution in proportion, for Al 2 o 3 The carrier is impregnated, dried and placed in a muffle furnace for calcination at 490°C for 6 hours. After cooling, it is impregnated with a mixed solution of Co and Zn nitrates again, and the catalyst is calcined under the same conditions. The bulk density of the catalyst was 0.90 g / ml. The catalyst number is A-2.

Embodiment 3

[0025] A kind of catalyst, described catalyst is Co-Zn / Al 2 o 3 , including the following components by weight: Co is 15.0%, Zn is 15.0%, and the rest is Al 2 o 3 .

[0026] A preparation method of catalyst, comprising the steps of: Al(OH) 3 Prepare a sodium metaaluminate solution with 40% NaOH, neutralize the precipitate with nitric acid, age, filter, wash, and roll into balls, dry, and roast to obtain spherical Al with a diameter of 1-3mm. 2 o 3 Carrier, the nitrate of Co and Zn is made into a mixed solution in proportion, for Al 2 o 3 The carrier is impregnated, dried and placed in a muffle furnace for calcination at 490°C for 6 hours. After cooling, it is impregnated with a mixed solution of Co and Zn nitrates again, and the catalyst is calcined under the same conditions. The bulk density of the catalyst was 0.90 g / ml. The catalyst number is A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com