Bismuth subnitrate and bismuth oxy iodide composite light catalyst, preparation method thereof and application of composite light catalyst

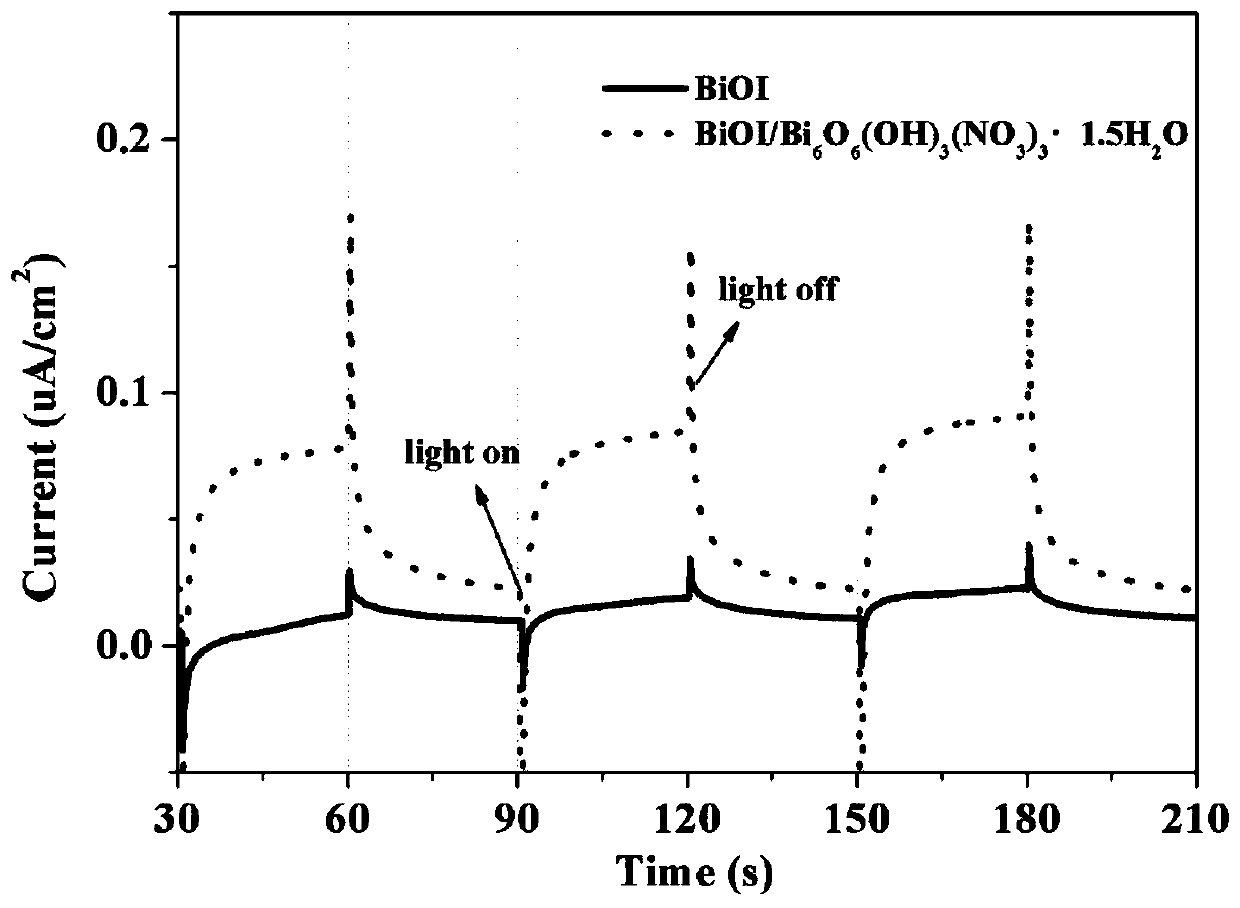

A technology of bismuth nitrate and recombination of light, which is applied in the field of photocatalysis, can solve the problems of low photoresponse ability and poor photocatalytic activity, and achieve the effects of improving separation efficiency, reducing transmission impedance, and inhibiting the recombination of photogenerated electrons and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] This embodiment proposes a method for preparing a composite photocatalyst of bismuth subnitrate and bismuth oxyiodide, comprising the following steps:

[0029] 1) dispersing iodized salt and bismuth salt containing at least bismuth nitrate in water respectively to obtain said iodized salt solution and said bismuth salt solution;

[0030]2) According to the molar ratio of iodine salt to bismuth in bismuth salt containing at least bismuth nitrate 0.5-1.5:1, add iodine salt solution to bismuth salt solution to obtain a black mixed solution, stir the black mixed solution for 10-60min to a red mixed solution Wherein, the iodized salt is potassium iodide and / or sodium iodide, and the bismuth salt containing bismuth nitrate at least is a mixture of bismuth nitrate or bismuth nitrate and other bismuth sources; further, the described bismuth source is iodine bismuth oxide and / or bismuth oxide;

[0031] 3) Transfer the mixed liquid obtained in step 2) to the autoclave according ...

Embodiment 1

[0037] This embodiment prepares flake BiOI / Bi 6 o 6 (OH) 3 (NO 3 ) 3 1.5H 2 The method of O photocatalyst is mainly realized by the following steps:

[0038] 1) Add 4mmol Bi(NO 3 ) 3 ·5H 2 O and 4mmol KI were respectively dispersed in 30mL deionized water, and stirred for 20min, then the KI aqueous solution was added to the Bi(NO 3 ) 3 ·5H 2 O solution, stirred for 60min to obtain a red mixed solution; wherein, Bi(NO 3 ) 3 ·5H 2 O is dispersed in the solution in the form of a suspension;

[0039] 2) Transfer the mixed solution obtained in step 1) to the autoclave according to 60% of the volume of the autoclave, and conduct a hydrothermal reaction at 160° C. for 6 hours. After the reaction, cool and filter; After repeated washing with ethanol and drying, the flaky BiOI / Bi 6 o 6 (OH) 3 (NO 3 ) 3 1.5H 2 O composite photocatalyst.

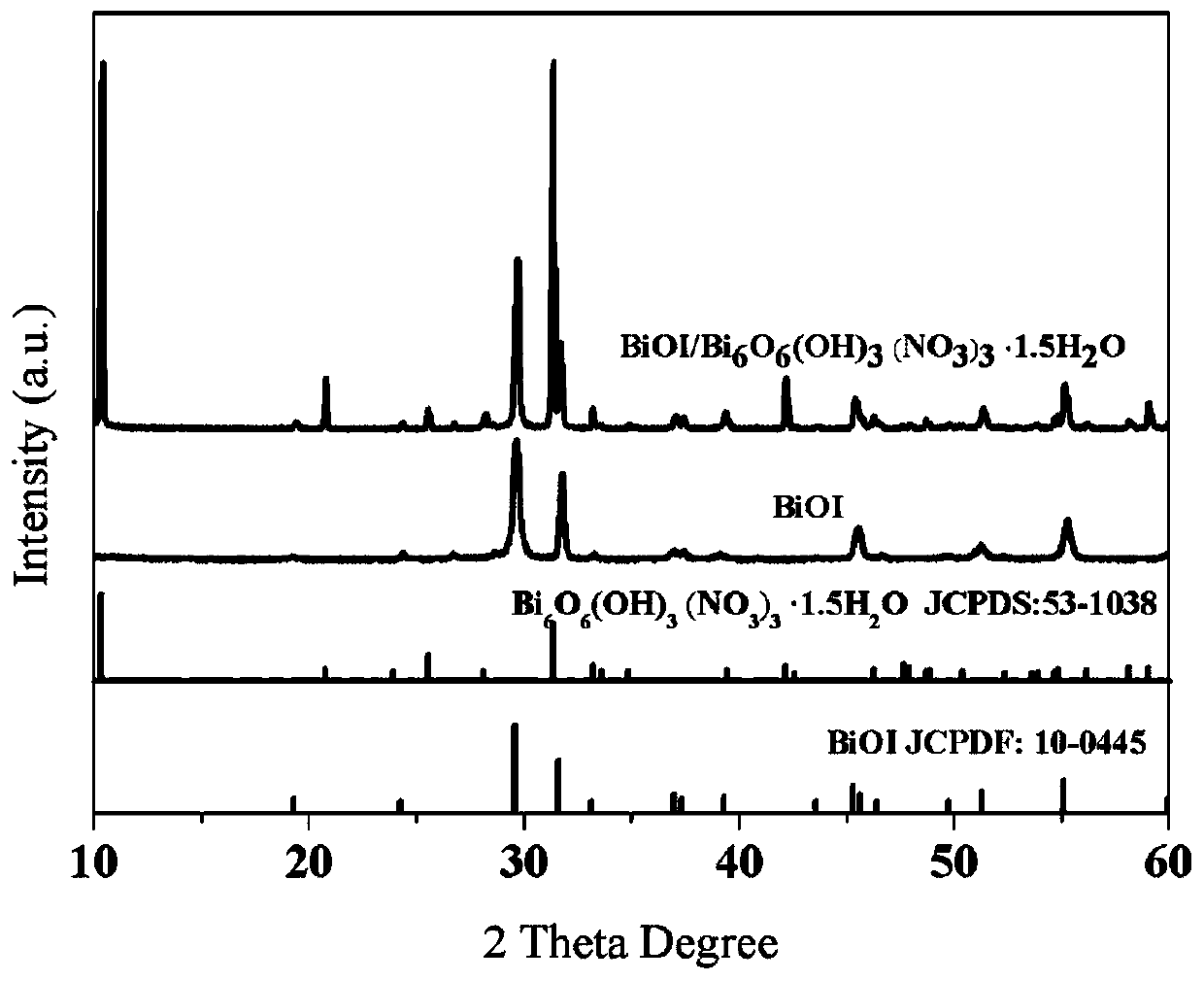

[0040] from figure 1 It can be seen from the figure that after the hydrothermal reaction, a large amount of iodine element parti...

Embodiment 2

[0042] This embodiment prepares flake BiOI / Bi 6 o 6 (OH) 3 (NO 3 ) 3 1.5H 2 The method of O photocatalyst is mainly realized by the following steps:

[0043] 1) Add 2mmol Bi(NO 3 ) 3 ·5H 2 O and 2mmol KI were respectively dispersed in 20mL deionized water, and stirred for 40min, then the KI aqueous solution was added to the Bi(NO 3 ) 3 ·5H 2 O solution, stirred for 30min to obtain a red mixed solution; wherein, Bi(NO 3 ) 3 ·5H 2 O is dispersed in the solution in the form of a suspension;

[0044] 2) Transfer the mixed liquid obtained in step 1) to the autoclave according to 80% of the volume of the autoclave, and conduct a hydrothermal reaction at 180° C. for 3 hours. After the reaction, cool and filter; Wash with ethanol repeatedly and dry to obtain flake BiOI / Bi 6 o 6 (OH) 3 (NO 3 ) 3 1.5H 2 O composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com