Chicken manure/corn straw composite co-pyrolysis activated carbon soil remediation agent, preparation method thereof and application of remediation agent

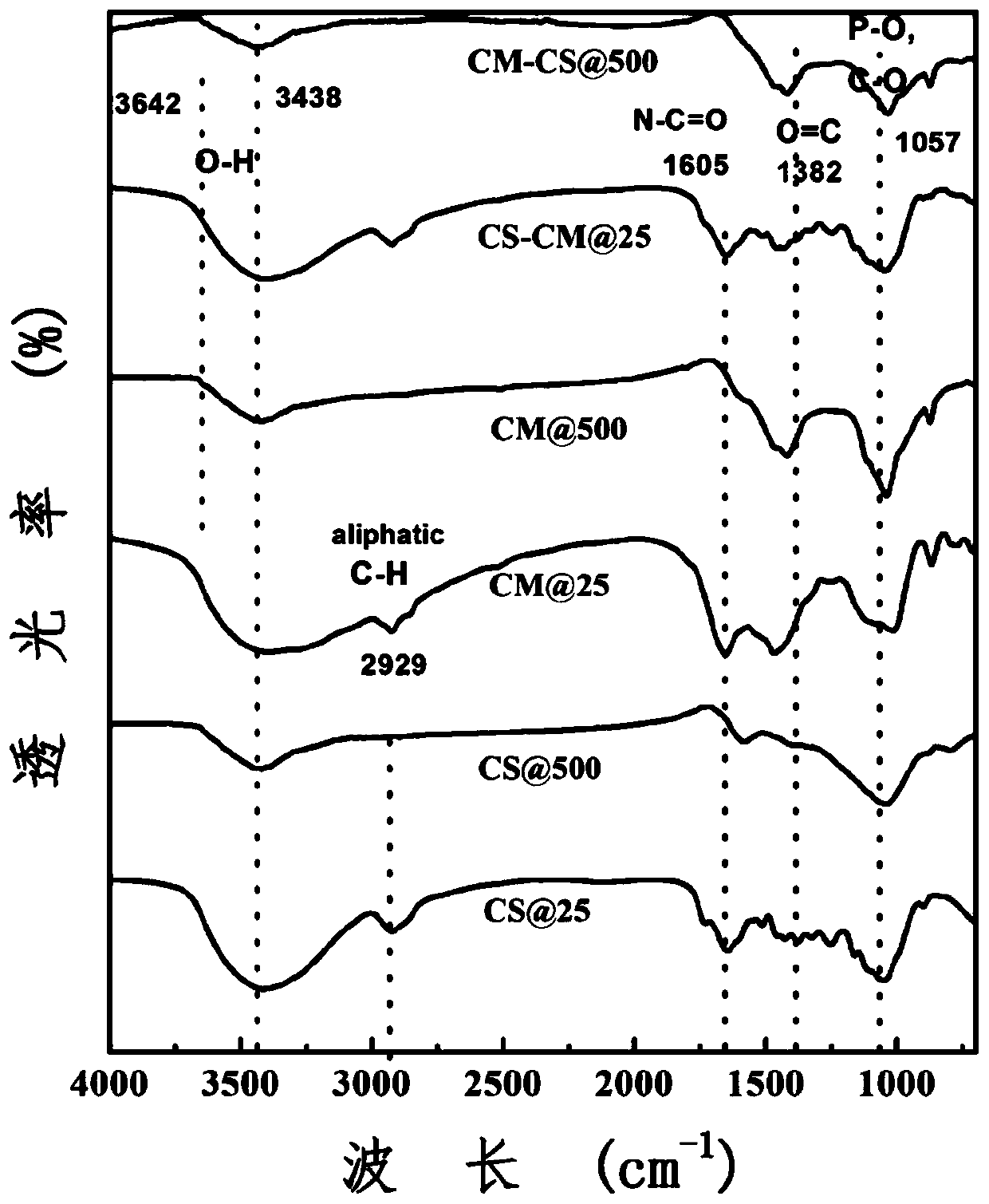

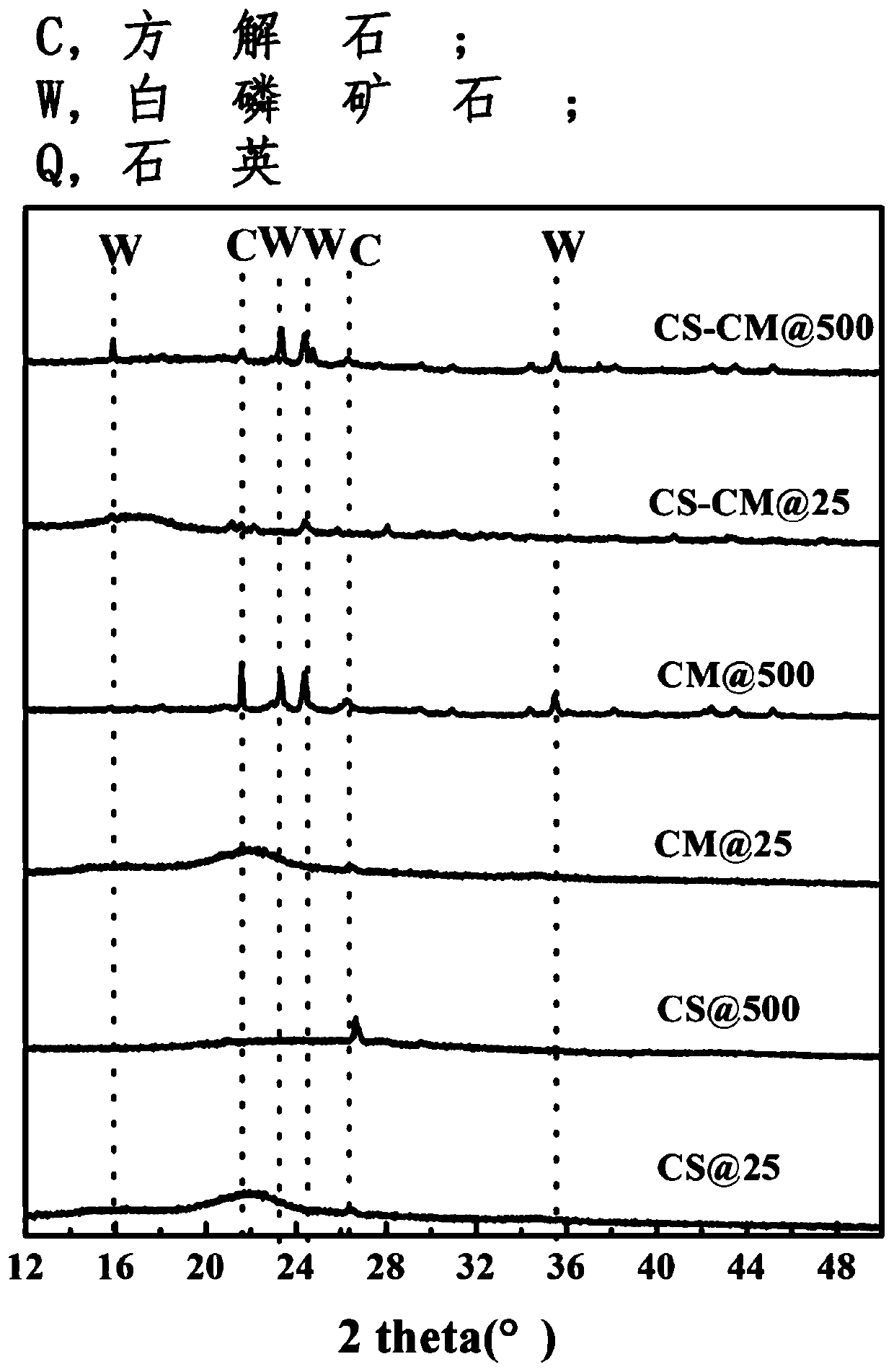

A soil remediation agent and corn stalk technology, applied in the field of organic dye contaminated soil adsorbent and heavy metal field, can solve problems such as negative impact on the soil environment, and achieve the effects of large ash content, developed pore structure and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Pretreatment for the preparation of chicken manure / corn stalk composite particles: chicken manure comes from a chicken farm in Yancheng, Jiangsu, and corn stalks come from a corn field in Yunnan; the raw materials are placed on iron trays and placed in a vacuum oven at 105°C for more than 12 hours. Ensure complete drying; use a large traditional Chinese medicine grinder for crushing (speed 25000r / min); then use an 80-mesh sieve to screen the required powder;

[0055] (2) Preparation of chicken manure / corn stalk composite spherical particles: the raw materials of chicken manure powder and corn stalk powder were respectively mixed at 0:10 (ie without chicken manure), 2:8, 4:6, 5:5, 6: 4. The mass ratio of 8:2, 10:0 (that is, without corn stalks) is mixed and placed in a 1000mL large beaker, and then the content is weighed to be 40%, which means corn starch / raw material (chicken manure + straw) = 40 %, that is, the amount of binder accounts for 40% of the cornstarch bi...

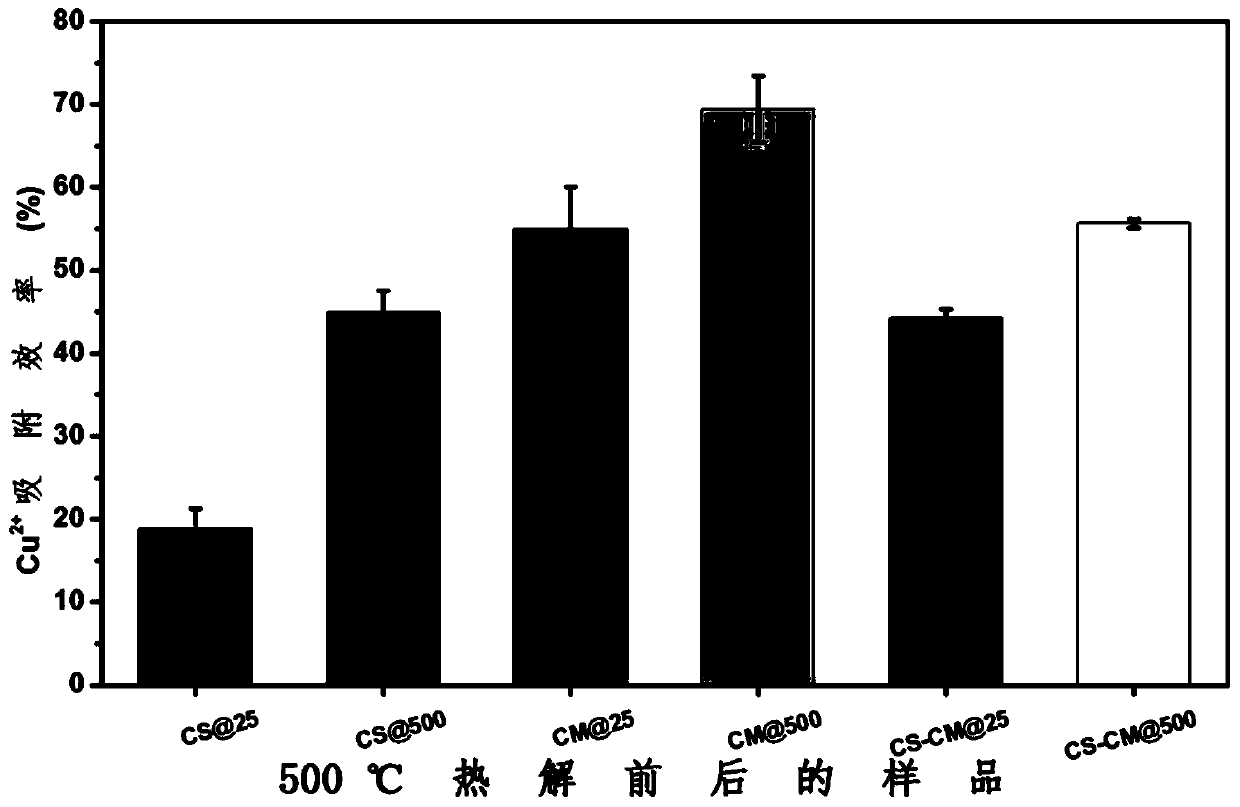

Embodiment 2

[0075] Apparent adsorption of soil for heavy metal adsorption: Weigh 0.8g of 20-mesh air-dried soil (the air-dried soil comes from South China Agricultural University, dig about 20cm deep, and the soil quality is uniform) and 0.16g of granular activated carbon (that is, the chicken manure prepared in Example 1 / Corn straw co-pyrolysis compound activated carbon heavy metal polluted soil remediation agent C 1 、C 2 、C 3 、C 4 、C 5 、C 6 ), placed in a 50mL centrifuge tube (polyethylene plastic bottle), the mass ratio of carbon to soil was 1:5, and 25mL of pH 4.8 buffer solution (containing 0.07mol / L sodium acetate and 0.03mol / L acetic acid) was added to the centrifuge tube, Place on a constant temperature shaker at 20°C and vibrate at 150rpm for 2h, then add 0.2mL of 0.2mol / L Cu(NO 3 ) 2 solution, so that the initial solution Cu 2+ The concentration is 1mmol / L; placed on a constant temperature oscillator at 20°C at 150rpm for 2h, then quickly taken out, placed in a centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com