Polydopamine propenoic acid-based polyurethane adhesive and preparation method thereof

A polydopamine propylene-based polyurethane and acrylic-based polyurethane technology, which is applied in the field of material science, can solve problems such as poor adhesive mechanical properties of adhesives, and achieve the effects of high reaction efficiency, wide application prospects, and green environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of PDMAPU adhesive includes the following steps:

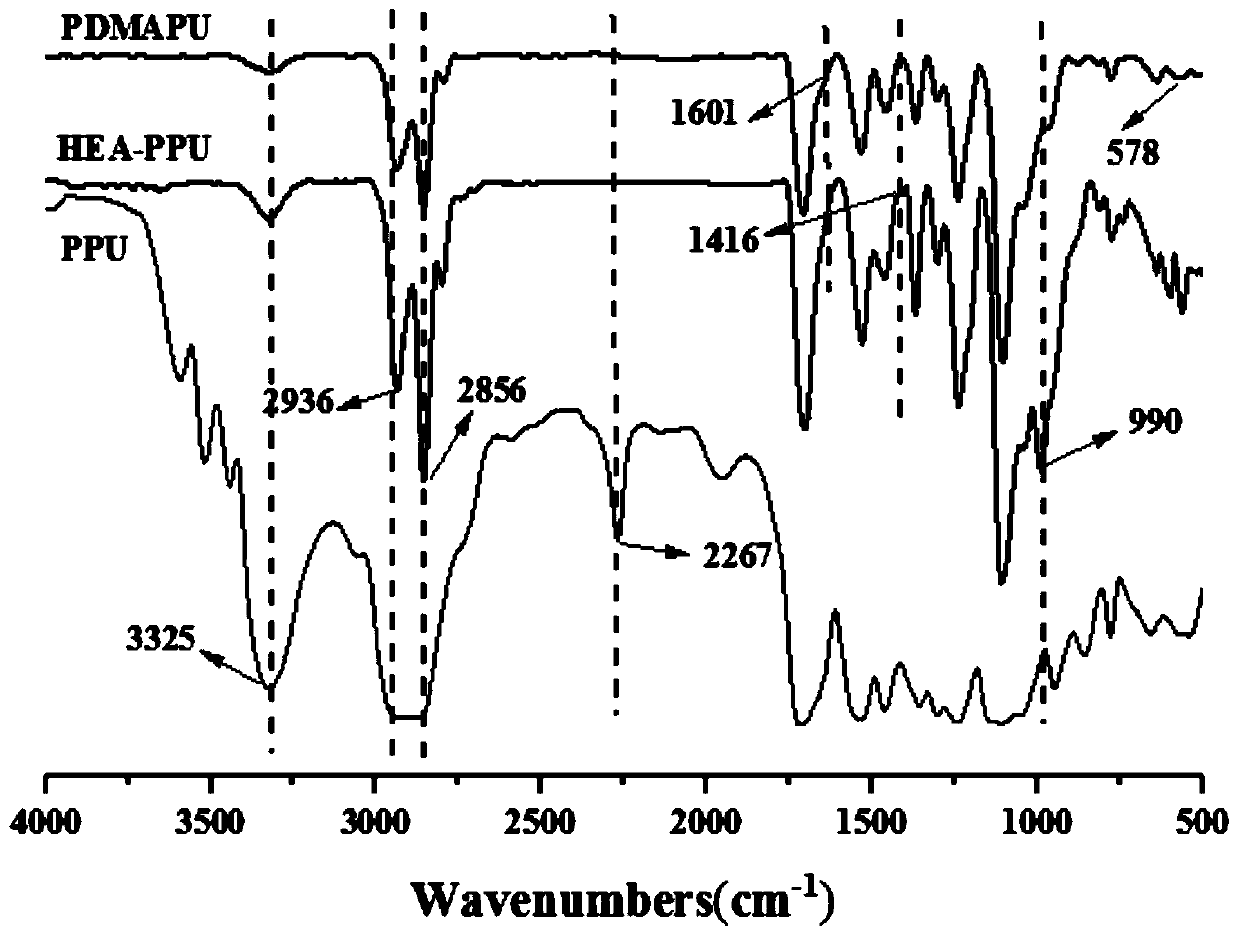

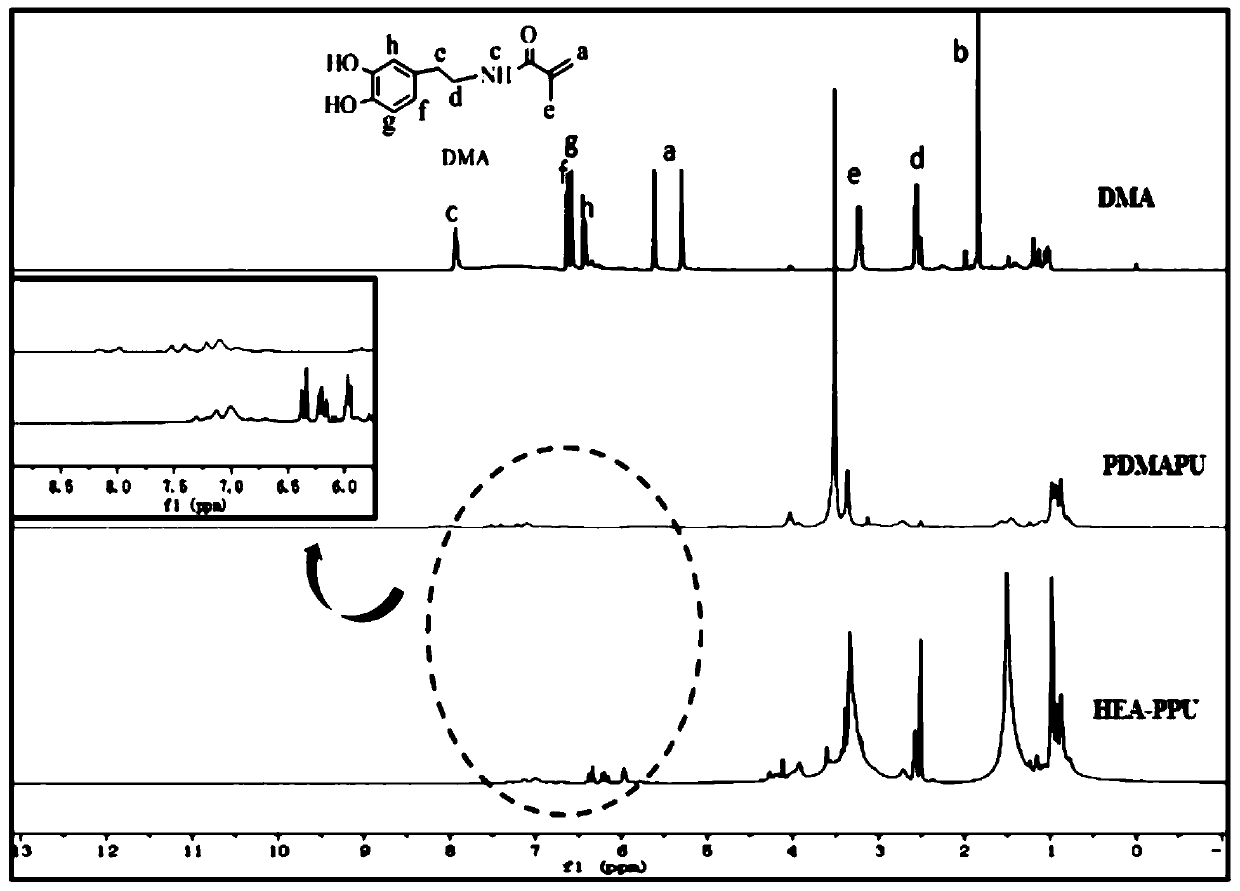

[0032] Step 1. Preparation of PPU

[0033] Add 25mmol of isophorone diisocyanate, 6.25mmol of polytetrahydrofuran ether (PTMG2000), 0.095mmol of dibutyltin dilaurate, and 4mmol of small molecule chain extender 1,4-butanediol into a stirrer, glass In a three-necked flask with a stopper, mix evenly, use a heat-collecting thermostatic heating magnetic stirrer to heat (oil bath), first react at 50°C for 30 minutes, then heat to 70°C for 1 hour, and then add 6.73mmol of carboxylic acid type hydrophilic Chain extender 2,2-bis(hydroxymethyl)propionic acid, chain extension reaction at 80℃ for 2.5h to obtain PPU;

[0034] Step 2. Preparation of HEA-PPU

[0035] Add 16mmol of hydroxyethyl acrylate (HEA) to 8mmol of PPU synthesized in step 1 for end-capping, and react at 70°C for 3h to obtain HEA-PPU;

[0036] Step 3: Preparation of PDMAPU adhesive

[0037] Take 2.67mmol of DMA dispersed in 10ml of acetone, and then ad...

Embodiment 2

[0039] A polydopamine propylene-based polyurethane adhesive and a preparation method thereof, including the following steps:

[0040] Step 1. Preparation of PPU

[0041] The preparation method is exactly the same as in Example 1;

[0042] Step 2. Preparation of HEA-PPU

[0043] Add 16 mmol methyl methacrylate to 8 mmol of the PPU synthesized in step 1 for end-capping, and react at 75°C for 2 hours to obtain HEA-PPU;

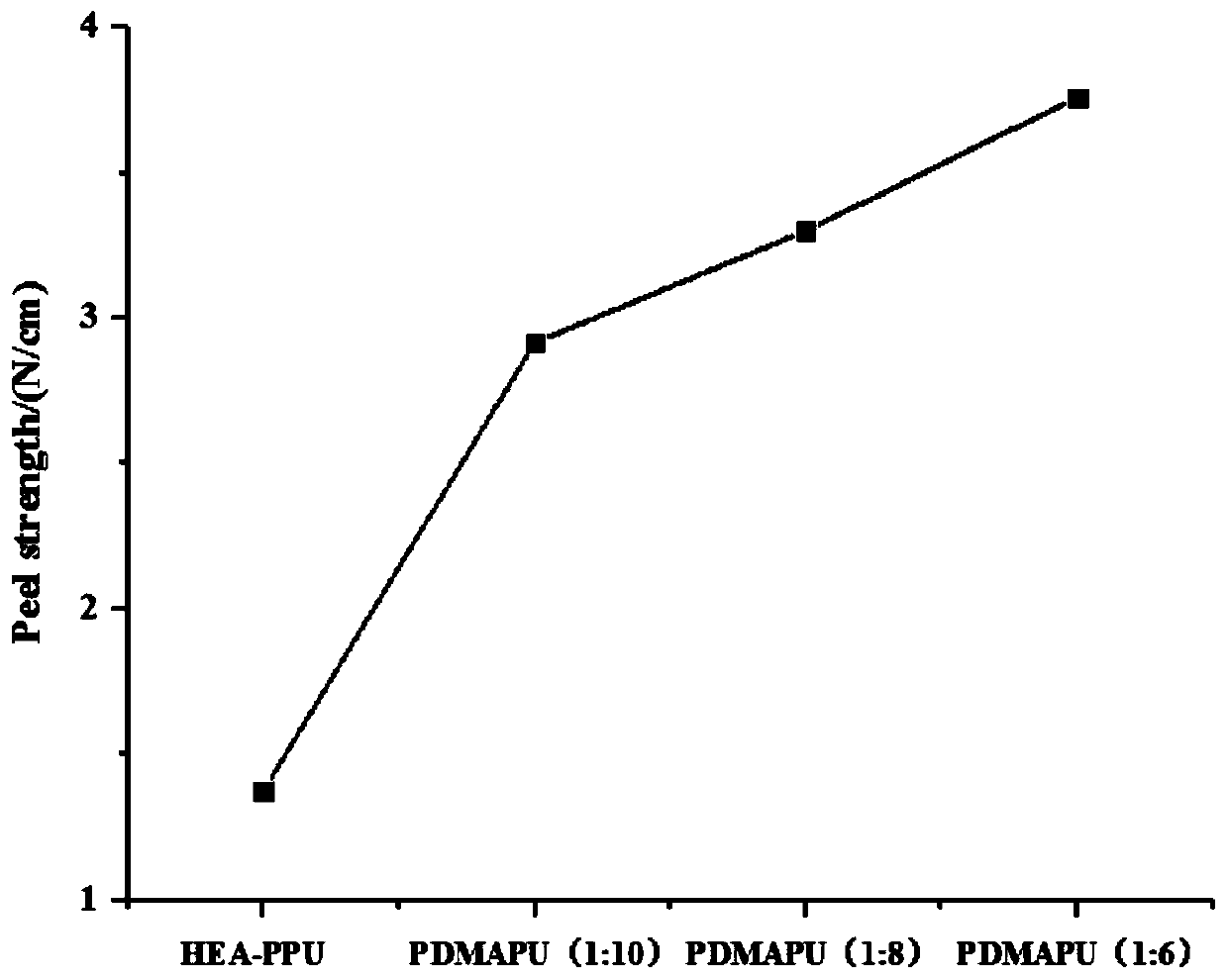

[0044] Step 3. Preparation of PDMAPU emulsion

[0045] Disperse 2.0mmol DMA in 10ml of acetone, then add it to the HEA-PPU prepared in step 2 with the molar ratio of DMA and the acrylic group in HEA-PPU of 1:8, and then add 0.25mmol of AIBN , Bubbling in argon gas for 35 minutes, stirring in an oil bath at 70°C for 3 hours to carry out the random double bond homopolymerization reaction between propenyl and methacrylamide groups, and finally neutralizing the product with triethylamine Salt is formed, then the acetone in the product is removed, and 31 g of deionized water i...

Embodiment 3

[0047] A polydopamine propylene-based polyurethane adhesive and a preparation method thereof, including the following steps:

[0048] Step 1. Preparation of PPU

[0049] The preparation method is exactly the same as in Example 1;

[0050] Step 2. Preparation of HEA-PPU

[0051] Add 16 mmol of 2-hydroxypropyl methacrylate to 8 mmol of the PPU synthesized in step 1 for end-capping, and react at 75°C for 2.5 h to obtain HEA-PPU;

[0052] Step 3. Preparation of PDMAPU emulsion

[0053] Take 1.6mmol of DMA dispersed in 10ml of acetone, and then add it to the HEA-PPU prepared in step 1 with the molar ratio of DMA and the acrylic group in HEA-PPU of 1:10, and then add 0.15mmol of AMBN , Bubbling in argon gas for 45 minutes, stirring in an oil bath at 75 ℃ and reacting for 2 hours to carry out the homopolymerization reaction of random double bonds between acrylic groups and methacrylamide groups, and finally neutralize the product with triethylamine Salt is formed, then the acetone in the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com