Natural gas concentrated transportation system based on cold energy circulation and concentrated transportation method

A natural gas and cold energy technology, which is applied in the field of natural gas collection and transportation systems, can solve the problems of uneconomical natural gas resource pipeline transportation, and achieve the effects of avoiding discharge losses, improving recycling efficiency, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

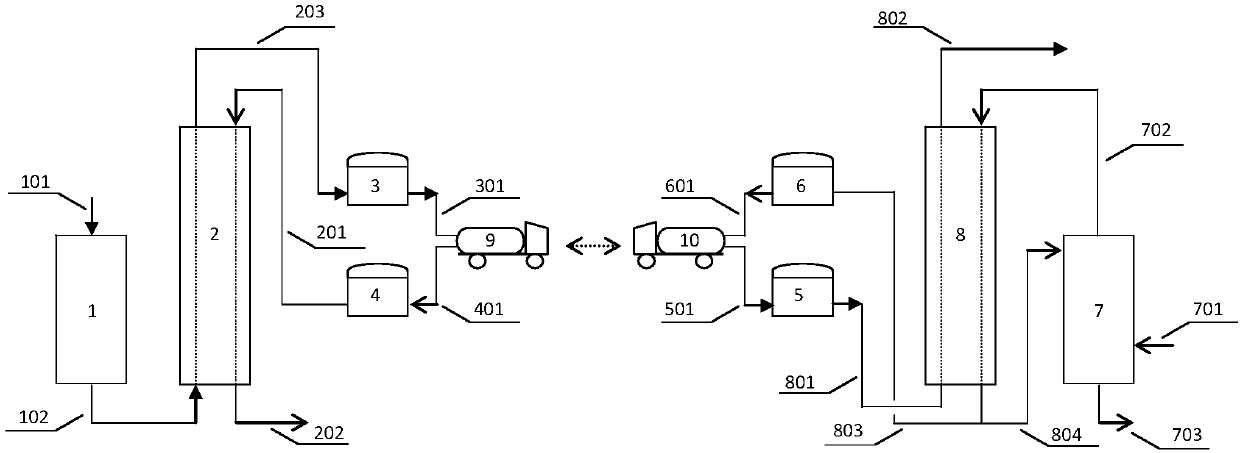

[0029] as attached figure 1 As shown, it is a natural gas collection and transportation system based on cold energy cycle of the present invention, including natural gas liquefaction system, transportation system and LNG cold energy utilization system, the natural gas-LN of purified natural gas in the natural gas liquefaction system 2 After the cold energy obtained in the heat exchanger 2 becomes LNG, it is transported to the LNG cold energy utilization system through the transportation system, and the cold energy of LNG is released to nitrogen, so that nitrogen becomes LN 2 , then LN 2 Natural gas transported to the natural gas liquefaction system through the transportation system-LN 2 In the heat exchanger 2, cold energy is provided for natural gas liquefaction, and the cold energy recovery and utilization process in the natural gas transportation system is realized.

[0030] Further, the natural gas liquefaction system also includes the LNG storage tank 3 for natural gas ...

Embodiment 2

[0038] LNG is usually transported under normal pressure or slightly positive pressure. In the natural gas-LN2 heat exchanger 2 of natural gas resources, the liquefaction pressure of GNG is 0.1MPa at normal pressure, and the corresponding temperature is -162°C. GNG can be liquefied without pressurization Correspondingly, at this time, the gasification pressure of LN2 in the natural gas-LN2 heat exchanger 2 can be 0.4-1.5MPa, and the corresponding gasification temperature is -182°C--163°C, that is, the LN2 gasification pressure is 0.4MPa, and the corresponding temperature is -182 °C; the gasification pressure of LN2 is 1.5MPa, and the corresponding temperature is -163 °C; correspondingly, the temperature of LNG in the liquefaction unit (2) is between -162 °C and -182 °C, which is higher than the freezing point of natural gas -183 °C. The GN2 waste generated by the liquefaction unit (2) is discharged, directly or pressurized to the pressure required by the user, and enters the use...

Embodiment 3

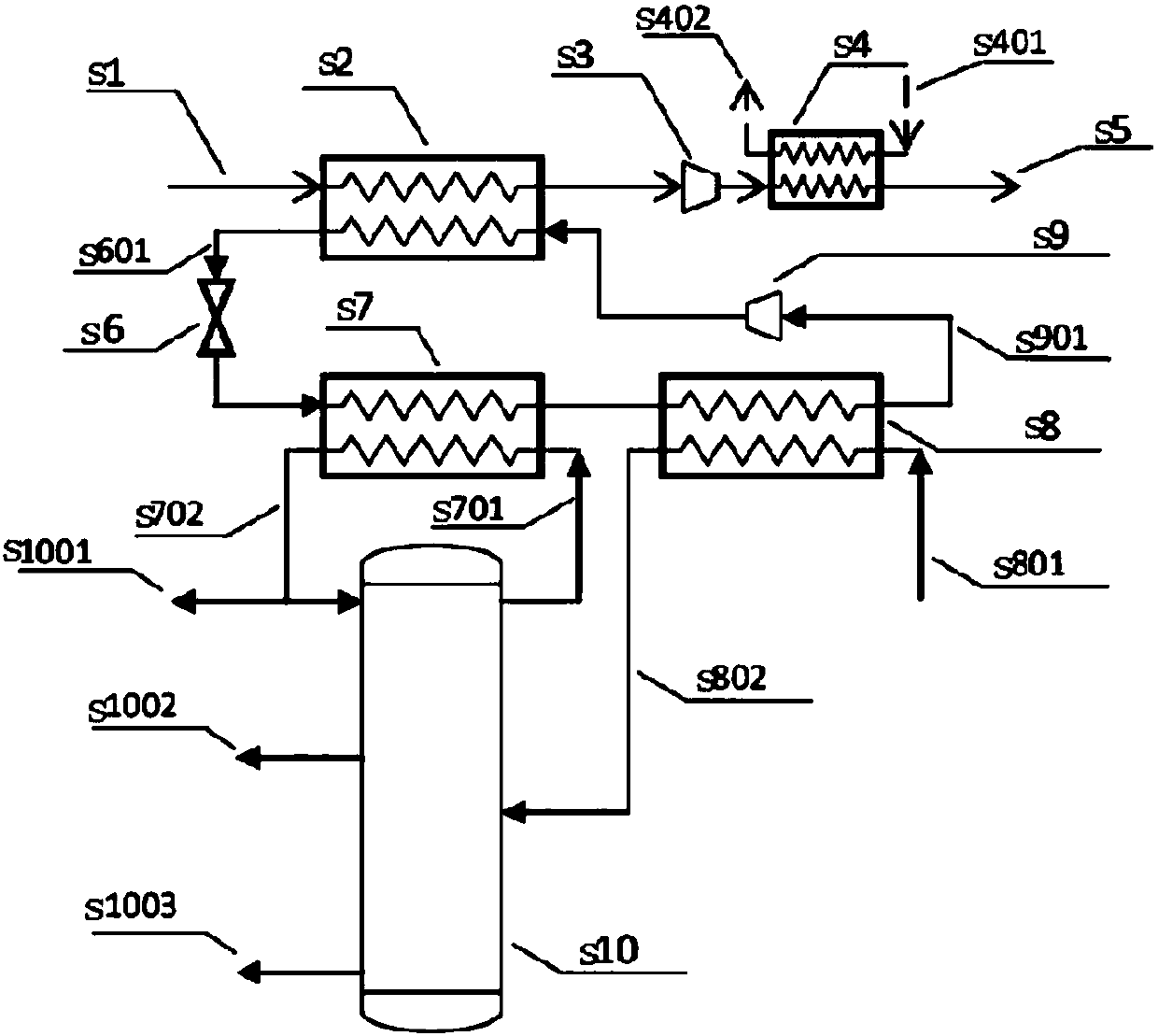

[0040] A natural gas consolidating system based on cold energy circulation of the present invention differs from Embodiment 1 only in that another different LNG cold energy utilization system is used; the LNG cold energy utilization system includes an LNG-argon heat exchanger S2, argon circulation system, air separation tower, natural gas gate station LNG storage tank 5 and natural gas gate station LN2 storage tank 6; the connection loop of LNG-argon heat exchanger S2, argon circulation system and air separation tower is recorded as based on argon Circulating LNG cold energy utilization system, as attached figure 2 shown.

[0041] Further, the argon circulation system includes a series connection composed of liquid argon pipeline S601, circulation argon throttling expansion valve S6, circulation argon heat exchanger, argon pipeline S901, circulation argon compressor S9 and LNG-argon heat exchanger S2 Loop; the circulating argon heat exchanger includes a circulating argon-nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com