Electroless plating process

A process, nickel-plating technology, applied in the direction of metal material coating process, circuit, printed circuit, etc., to achieve the effect of thin film and excellent packaging characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

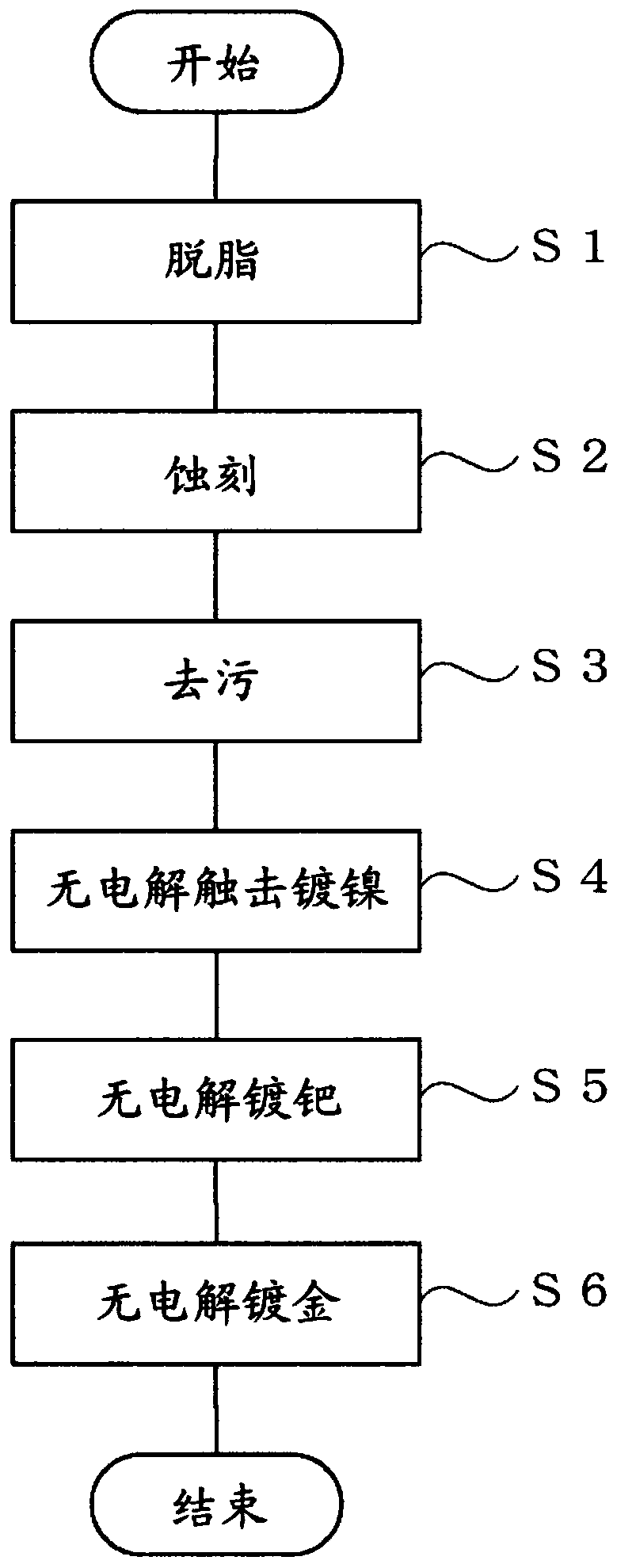

[0089] In the electroless plating process of this embodiment, by sequentially figure 1 In each of the shown steps S1 to S6 (all six steps), a Ni / Pd / Au film is formed on the surface of the copper material. After performing the above-mentioned degreasing step (S1), etching step (S2), and desmearing step (S3) in sequence, an electroless nickel strike plating step (S4) is performed. In the electroless nickel strike plating step ( S4 ), the copper material is immersed in an electroless nickel strike plating solution having the following composition to form a nickel plating film on the surface of the copper material. The electroless nickel strike plating solution is prepared by mixing nickel sulfate hexahydrate, DL-malic acid and water to form an aqueous solution containing a nickel complex, and then adding dimethylamine borane to it and stirring. . While the copper material is immersed in the electroless nickel strike plating solution, the electroless nickel strike plating solut...

reference example 1

[0111] The electroless plating process of this reference example was performed in the same manner as Comparative Example 1 except that the palladium catalyst application treatment ( S14 ) was not performed before the electroless nickel plating ( S15 ). The electroless plating process of this reference example has six steps in total.

reference example 2

[0113] The electroless plating process of this reference example was performed in the same manner as Comparative Example 2 except that the palladium catalyst application treatment (S14) was not performed before the electroless nickel plating (S15).

[0114]

[0115] 1. Evaluation of nickel-plated film

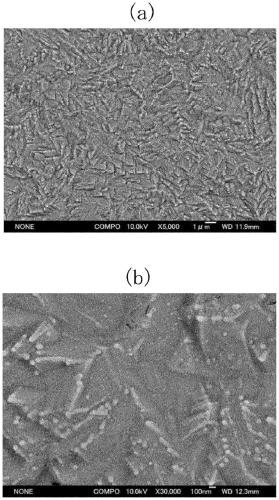

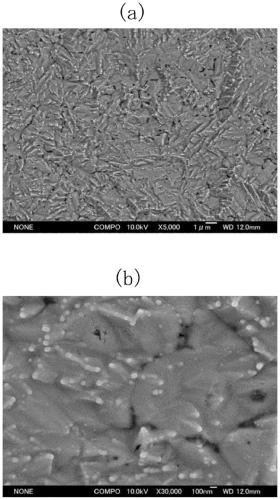

[0116] First, proceed to the electroless nickel strike plating process (S4) of the electroless plating process of Example 1, or proceed to the electroless nickel plating process of the electroless plating process of Comparative Example 1 and Comparative Example 2 (S15) , thereby forming a nickel-plated film with a film thickness of 0.01 μm on the surface of the copper material. The following evaluation was performed about the obtained nickel plating film.

[0117] 1-1. Nickel Precipitation

[0118] Here, a test plate was used in which 30 copper pads with a diameter of 0.45 mm were arranged in a grid at intervals of 30 μm on an insulating base material. Then, proceed to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com