Preparation method of pressure-sensitive film, pressure-sensitive film and pressure sensor

A pressure-sensitive film, extrusion grinding technology, applied in the preparation of pressure-sensitive film, pressure-sensitive film and pressure sensor field, can solve the problems of high cost, unstable pressure sensor quality, etc., achieve small detection limit, excellent piezoresistive effect , conductivity and piezoresistive effects can be controlled and adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Mix graphite and 150-mesh cubic silicon carbide evenly, and then put them into a mortar grinder, wherein the mass ratio of graphite to silicon carbide is 1:10. Apply 100N / cm to the mortar 2 Extrusion grinding is carried out with the action force, and the grinding time is 5h.

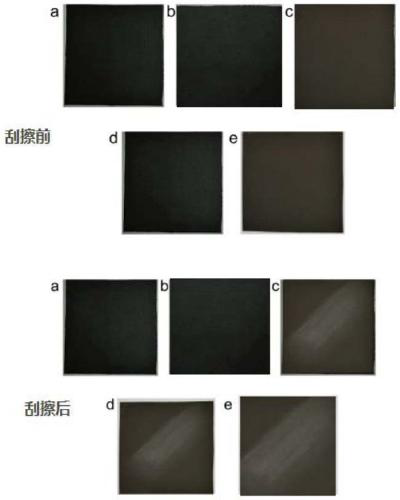

[0040] Step 2, transfer the ground mixture to dichloromethane, shake it up, ultrasonically disperse, then let stand for 2 days or centrifuge 10min in a centrifuge at 1000rpm, take the supernatant to obtain an organic solution containing graphene, such as figure 1 (left) shown. The graphene has a thickness of 0.35-20 nm and a lateral dimension of 0.1-20 μm.

[0041] Step 3, the polyurethane is added into dichloromethane to dissolve to obtain an organic solution containing polyurethane. The organic solution containing graphene and the organic solution containing polyurethane are mixed together, and the mass ratio of graphite to polyurethane is 100:57 for preparation to obtain a mixed solu...

Embodiment 2

[0045] Step 1: Mix graphite, black arsenic and phosphorus with 150-mesh cubic silicon carbide uniformly at a mass ratio of 93:7, and then put them into a mortar grinder, wherein the mass ratio of graphite to cubic boron nitride is 1:10. Apply 100N / cm to the mortar 2 Extrusion grinding is carried out with the action force, and the grinding time is 5h.

[0046] Step 2, transfer the ground mixture to dichloromethane, shake it up, ultrasonically disperse, then let it stand for 2 days or centrifuge it in a centrifuge at 1000rpm for 10min, take the supernatant, and obtain a mixture containing two-dimensional graphene and two-dimensional graphene. Organic solutions of black arsenic and phosphorus, such as figure 1 (right) shown. Among them, the thickness of graphene and two-dimensional black arsenic phosphorus is 0.35-20 nm, and the lateral size is 0.1-20 μm.

[0047] Step 3, the polyurethane is added into dichloromethane to dissolve to obtain an organic solution containing polyur...

Embodiment 3

[0051] In step 1, the finished graphene is added into dichloromethane for ultrasonic dispersion, and the graphene dispersion is obtained by ultrasonication for 2 hours.

[0052] Step 2, dissolving the polyurethane into dichloromethane to obtain a polyurethane dispersion.

[0053] In step 3, the graphene dispersion and the polyurethane dispersion are mixed together and stirred to obtain a viscous mixture. Wherein, the mass ratio of graphene and polyurethane is 100:57.

[0054] Step 4: Spin-coat the viscous mixture prepared in Step 3 to form a film, and then heat and solidify at 60° C. for 2 hours, so that the viscous mixture is polymerized. Dichloromethane evaporates to form a pressure-sensitive film composed of graphene and polyurethane, such as figure 2 as shown in c.

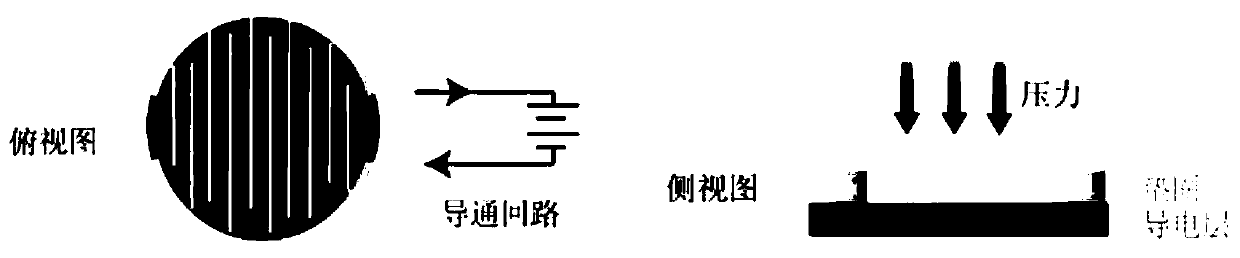

[0055] Step five, the pressure-sensitive film that step four makes according to image 3 The pressure sensor structure shown was assembled to fabricate the pressure sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com