Quick film removing and firm tin soldering grouping method for soft-packed lithium battery with low resistance, low heat and large over-current

A soft-pack lithium battery and tin brazing technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of laser head loss, high replacement rate, can not withstand repeated bumps, and affect over-power, etc. The effect of increasing cost and flight weight, avoiding system errors, and ensuring flight safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

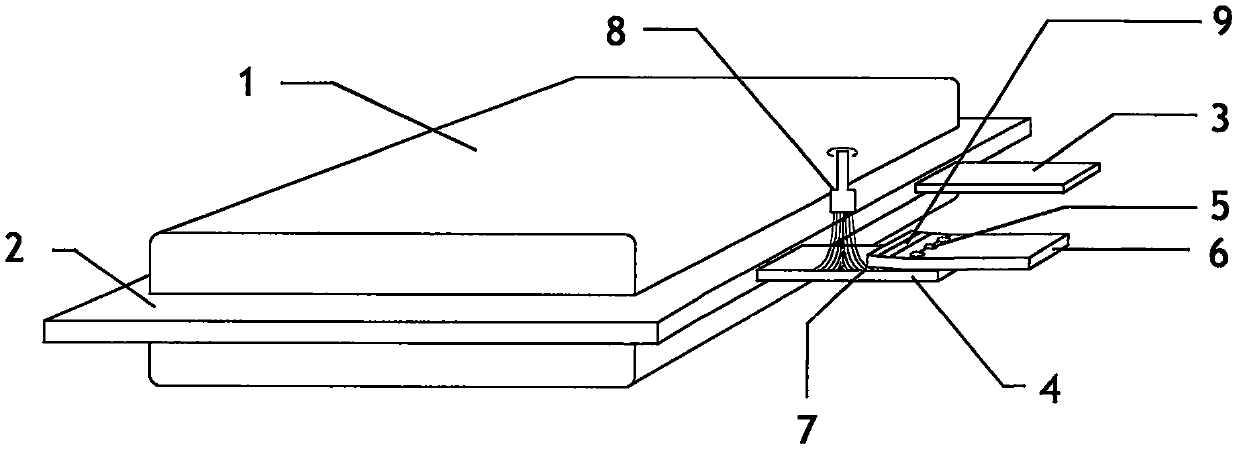

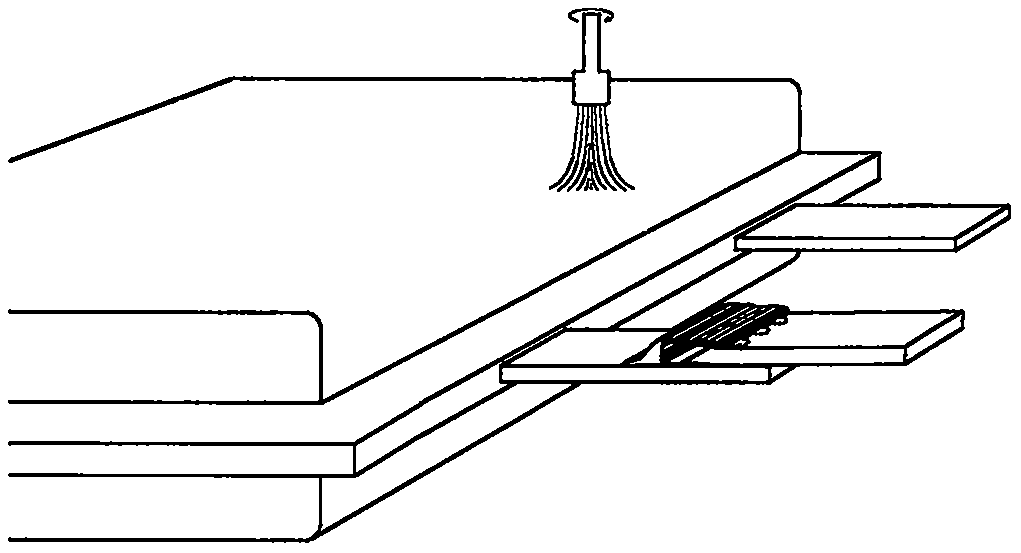

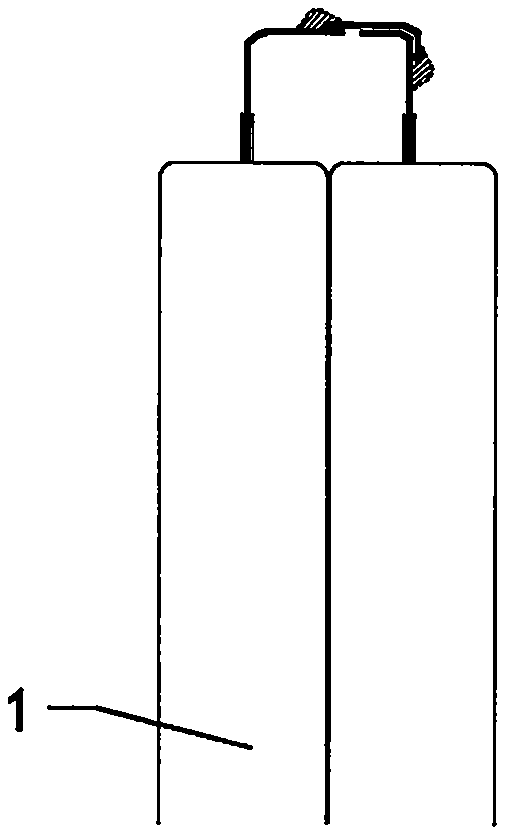

[0017] From simple to complex, we first introduce pre-fastening by traditional spot welding and hot pressing. See figure 1 , there is a pressing edge 2 around the soft package monomer 1, a negative electrode sheet 3 and a positive electrode aluminum sheet 4 at the front end, and the positive electrode aluminum sheet 4 only needs a few "points", and the solder joint 5 can pre-tighten the adapter sheet 6. Slightly raised micro-slits 7 are naturally formed. Use a rotating wire brush head 8 to polish the aluminum surface at the joint—including the micro-slits 7, to remove the aluminum oxide surface layer, and brush the nickel surface 9 of the adapter piece by the way.

[0018]Immediately afterwards, you can use the soldering aluminum solder wire containing flux, and the tin brazing of the two can be quickly completed by the soldering iron tip. See figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com