Silicon-based negative electrode electrolyte and lithium ion power battery

A silicon-based negative electrode and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve the problems of fluoroethylene carbonate defluorination reaction, battery capacity attenuation, battery internal resistance increase, etc., to achieve reduced gas production, small internal resistance, Effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

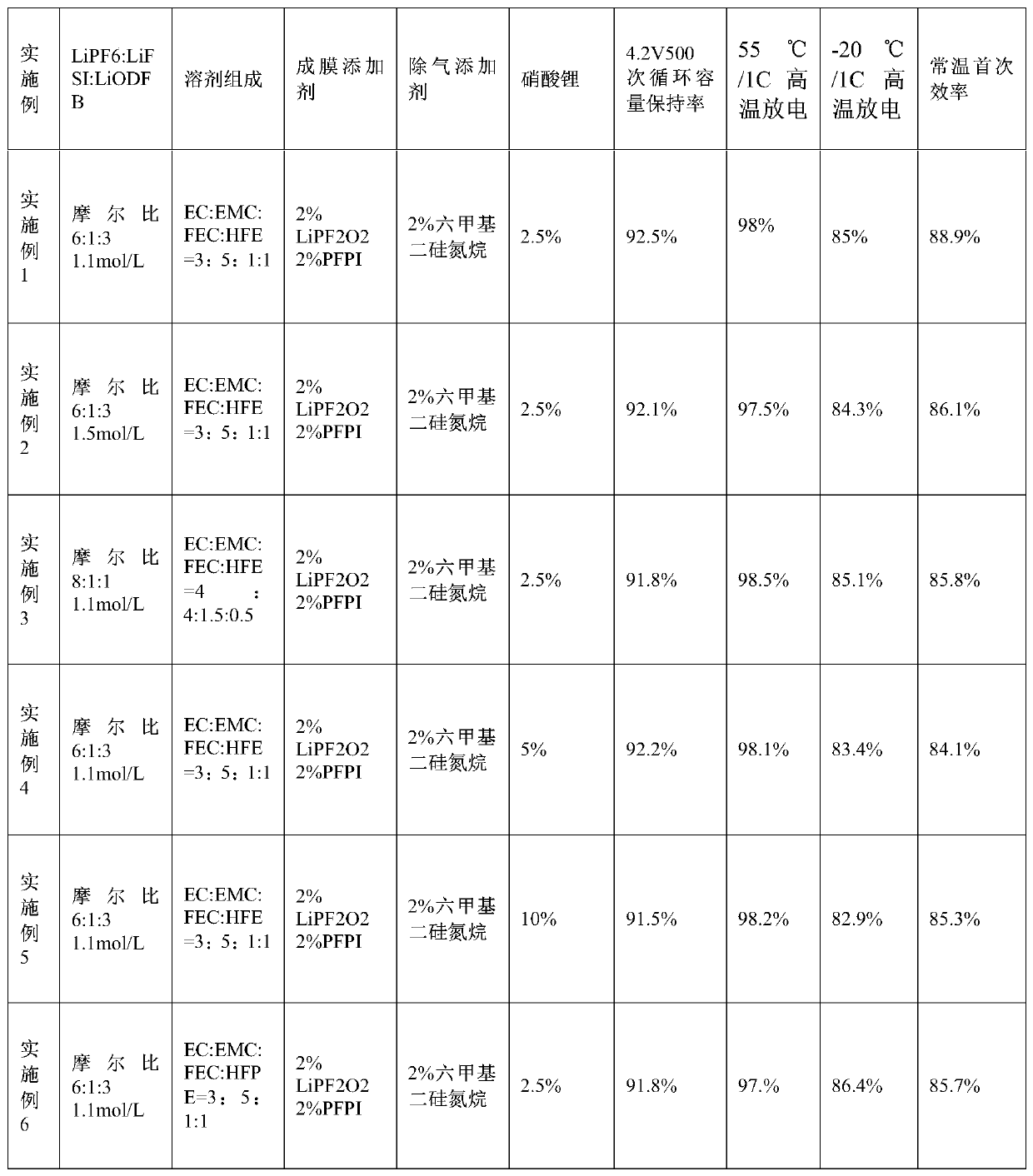

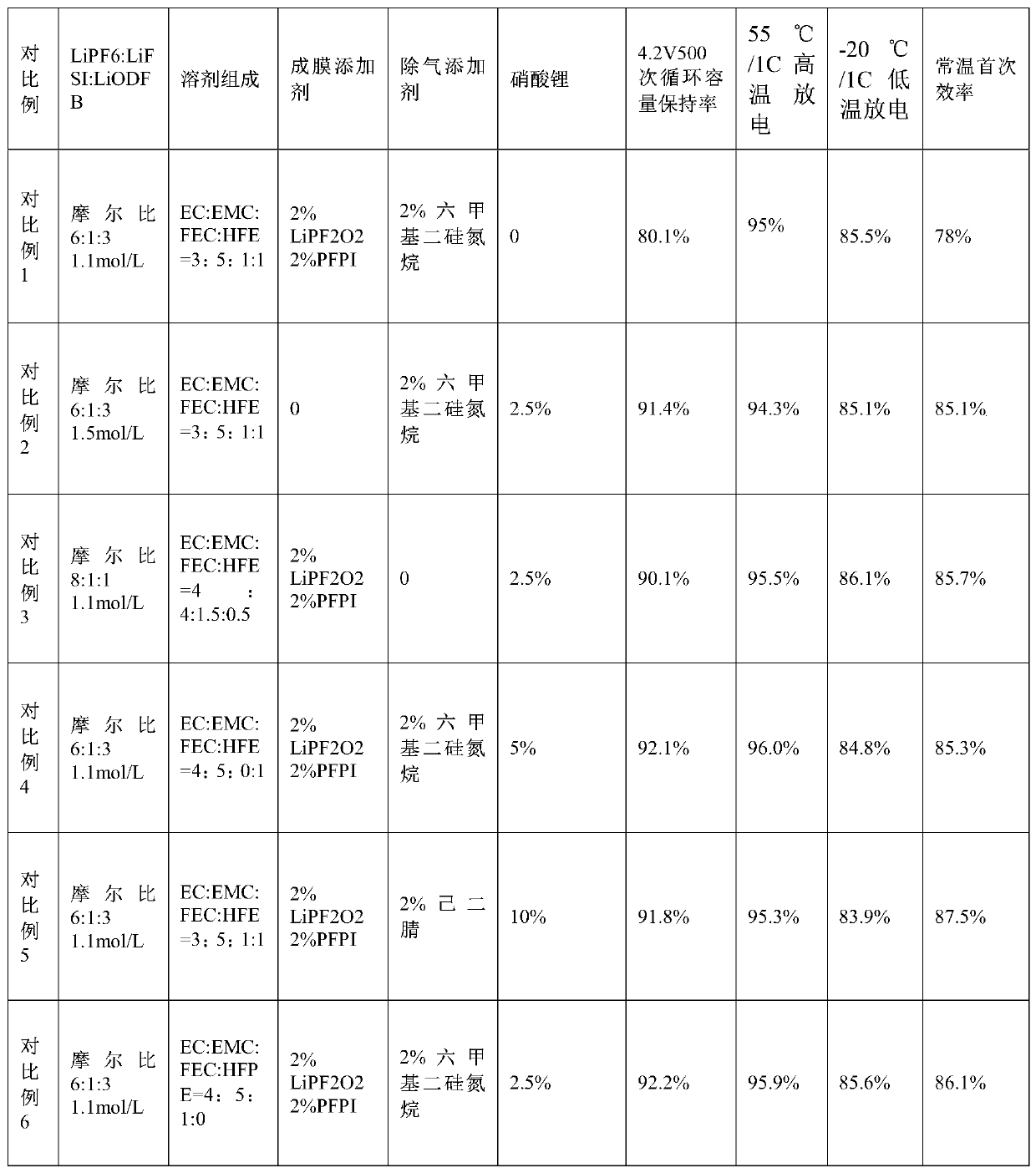

Embodiment 1

[0022] The electrolytic solution for a power battery provided in this embodiment includes a highly stable mixed lithium salt and an organic solvent containing a fluorinated ether, wherein the lithium salt is lithium bisfluorosulfonyl imide (LiFSI), lithium bisfluorooxalate borate (LiODFB ) and lithium hexafluorophosphate, the molar concentration ratio of lithium hexafluorophosphate, lithium bisfluorosulfonimide, and lithium bisfluorooxalate borate is 6:3:1, the concentration of lithium salt is 1.1mol / L, and the organic solvent is ethylene carbonate, ethyl methyl carbonate , fluoroethylene carbonate and hydrofluoroether tetrafluoroethyl tetrafluoropropyl ether (HFE) are mixed in a mass ratio of 3:5:1:1. The film-forming additive is lithium difluorophosphate (LiPF 2 o 2 ) and pentafluorophenyl isocyanate (PFPI), the quality of the two film-forming additives accounts for 2% of the electrolyte quality respectively, and the degassing additive is hexamethyldisilazane, which account...

Embodiment 2

[0026] The electrolytic solution for a power battery provided in this embodiment includes a highly stable mixed lithium salt and an organic solvent containing a fluorinated ether, wherein the lithium salt is lithium bisfluorosulfonyl imide (LiFSI), lithium bisfluorooxalate borate (LiODFB ) and lithium hexafluorophosphate, the molar concentration ratio of lithium hexafluorophosphate, lithium bisfluorosulfonimide, and lithium bisfluorooxalate borate is 6:3:1, the concentration of lithium salt is 1.5mol / L, and the organic solvent is ethylene carbonate, ethyl methyl carbonate , fluoroethylene carbonate and hydrofluoroether tetrafluoroethyl tetrafluoropropyl ether (HFE) are mixed in a mass ratio of 3:5:1:1. The film-forming additive is lithium difluorophosphate (LiPF 2 o 2 ) and pentafluorophenyl isocyanate (PFPI), the quality of the two film-forming additives accounts for 2% of the electrolyte quality respectively, and the degassing additive is hexamethyldisilazane, which account...

Embodiment 3

[0030] The electrolytic solution for a power battery provided in this embodiment includes a highly stable mixed lithium salt and an organic solvent containing a fluorinated ether, wherein the lithium salt is lithium bisfluorosulfonyl imide (LiFSI), lithium bisfluorooxalate borate (LiODFB ) and lithium hexafluorophosphate, the molar concentration ratio of lithium hexafluorophosphate, lithium bisfluorosulfonimide, and lithium bisfluorooxalate borate is 8:1:1, the lithium salt concentration is 1.1mol / L, and the organic solvent is ethylene carbonate, ethyl methyl carbonate , fluoroethylene carbonate and hydrofluoroether tetrafluoroethyl tetrafluoropropyl ether (HFE) are mixed in a mass ratio of 4:4:1.5:0.5. The film-forming additive is lithium difluorophosphate (LiPF 2 o 2 ) and pentafluorophenyl isocyanate (PFPI), the quality of the two film-forming additives accounts for 2% of the electrolyte quality respectively, and the degassing additive is hexamethyldisilazane, which accoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com