Graphene mask fabric and preparation method thereof

A technology of graphene surface and ene mask, which is applied in the direction of chemical instruments and methods, pharmaceutical formulations, rayon manufacturing, etc., can solve the problems of dust, weak adsorption capacity of cosmetics, poor antibacterial effect, etc., to promote cross-linking and reduce barrier , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

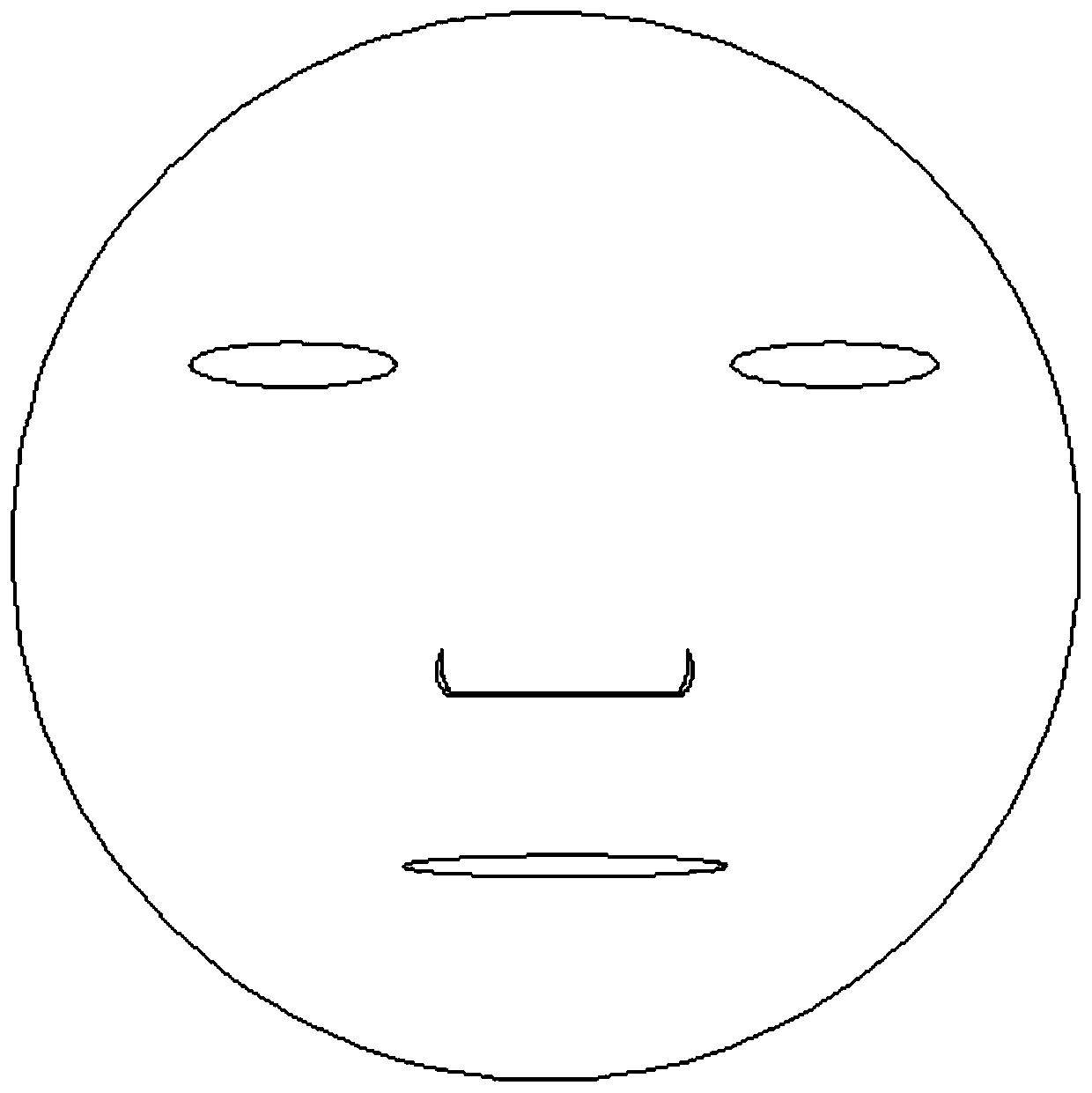

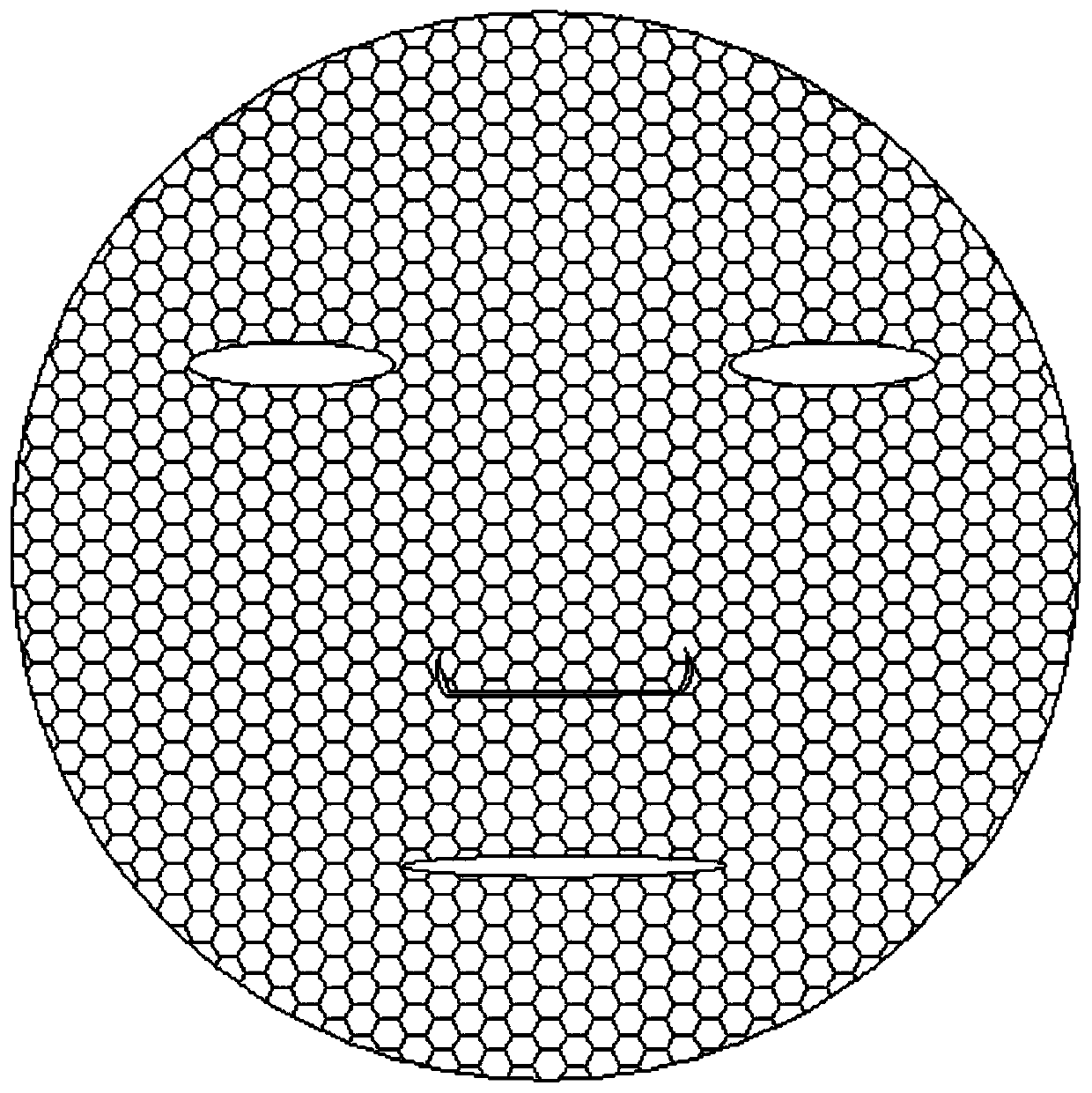

Image

Examples

preparation example Construction

[0039] A method for preparing graphene mask cloth includes the following steps:

[0040] (1) Take the corn cob and smash it through a 100 mesh sieve in a pulverizer. The sieved material is collected and added with a mass fraction of 12% sodium carbonate solution at a mass ratio of 1:6~10. Stir at 400~700r / min at 30~45℃ Mix for 30~55min, filter, take the filter cake and wash 2~4 times, take the filter cake according to the mass ratio of 1:7~12, add 15% HCl solution and mix for 30~50min, suction filter, collect the filter residue in a microwave oven Treated with 400W power for 4-7min to obtain the processed material, according to mass parts, take 20-30 parts of processed material and 1~3 parts of FeCl 2 , 1~3 parts FeCl 3 , Mix 2-5 parts of potassium chloride and 150-200 parts of water in the reactor, stir at 40~55℃, 350~550r / min for 1~3h, ultrasonic treatment at 45~55kHz frequency for 12~20min, get ultrasound Treat the material and evaporate under reduced pressure to a constant we...

Embodiment 1

[0050] A method for preparing graphene mask cloth includes the following steps:

[0051] (1) Take the corncob and smash through a 100 mesh sieve in a pulverizer, collect the sieved material and add 12% sodium carbonate solution with a mass fraction of 1:6, stir and mix for 30 minutes at 30°C and 400r / min, filter, and take Wash the filter cake twice with water, take the filter cake and add 15% HCl solution with a mass fraction of 1:7 to mix and stir for 30 minutes, suction filter, collect the filter residue in a microwave oven and treat it with 400W power for 4 minutes to obtain the processed material, calculated by mass parts , Take 20 parts of processed material, 1 part of FeCl 2 , 1 part FeCl 3 , 2 parts of potassium chloride and 150 parts of water are mixed in the reaction kettle, stirred at 40°C at 350r / min for 1h, then ultrasonically treated at 45kHz frequency for 12min to obtain ultrasonic treatment material, and evaporated under reduced pressure to constant weight to obtain...

Embodiment 2

[0061] A method for preparing graphene mask cloth includes the following steps:

[0062] (1) Take the corncob and pulverize it through a 100-mesh sieve in a pulverizer, collect the sieved material and add 12% sodium carbonate solution at a mass ratio of 1:10, stir and mix at 700r / min for 55 minutes at 45°C, filter, and take The filter cake was washed 4 times with water, and the filter cake was added with a mass fraction of 15% HCl solution at a mass ratio of 1:12, mixed and stirred for 50 minutes, suction filtered, and the filter residue was collected in a microwave oven and treated with 400W power for 7 minutes to obtain the processed material, calculated by mass parts , Take 30 parts of processed material, 3 parts of FeCl 2 , 3 parts FeCl 3 , 5 parts of potassium chloride and 200 parts of water are mixed in the reaction kettle, stirred at 55°C at 550r / min for 3h, then ultrasonically treated at 55kHz frequency for 20min to obtain ultrasonic treatment material, and evaporated unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com