Preparation methods for germanium-antimony-tellurium powder and target material

A germanium antimony tellurium and powder technology is applied in the field of phase change storage material preparation, which can solve the problems of uneven composition of germanium antimony tellurium ternary alloy, element segregation, low material density, etc. Relatively high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention proposes a preparation method of germanium antimony tellurium powder, which comprises the following steps:

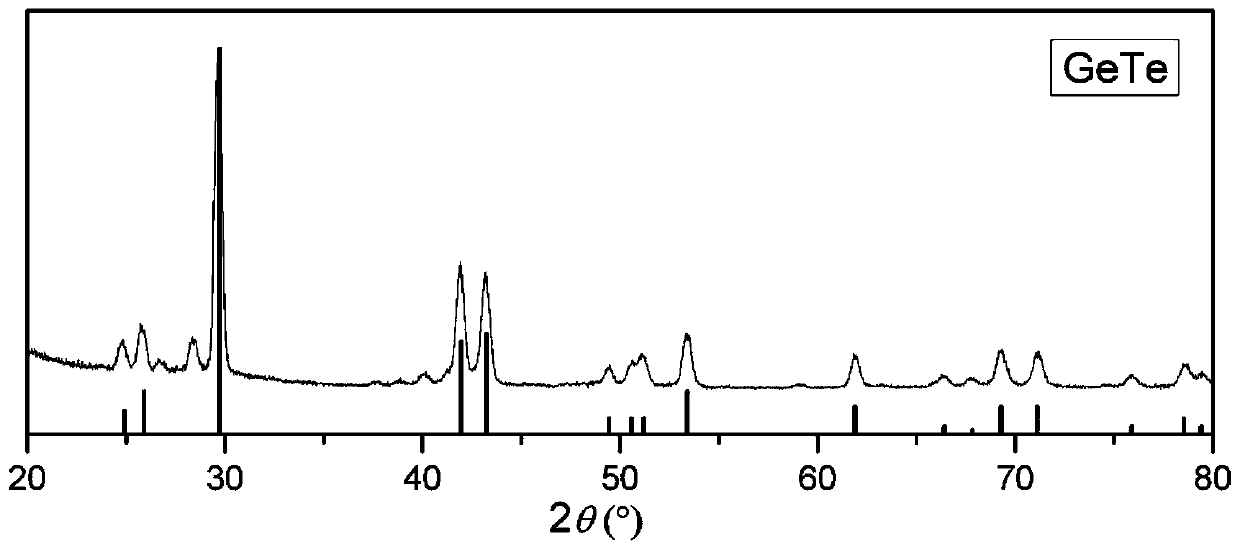

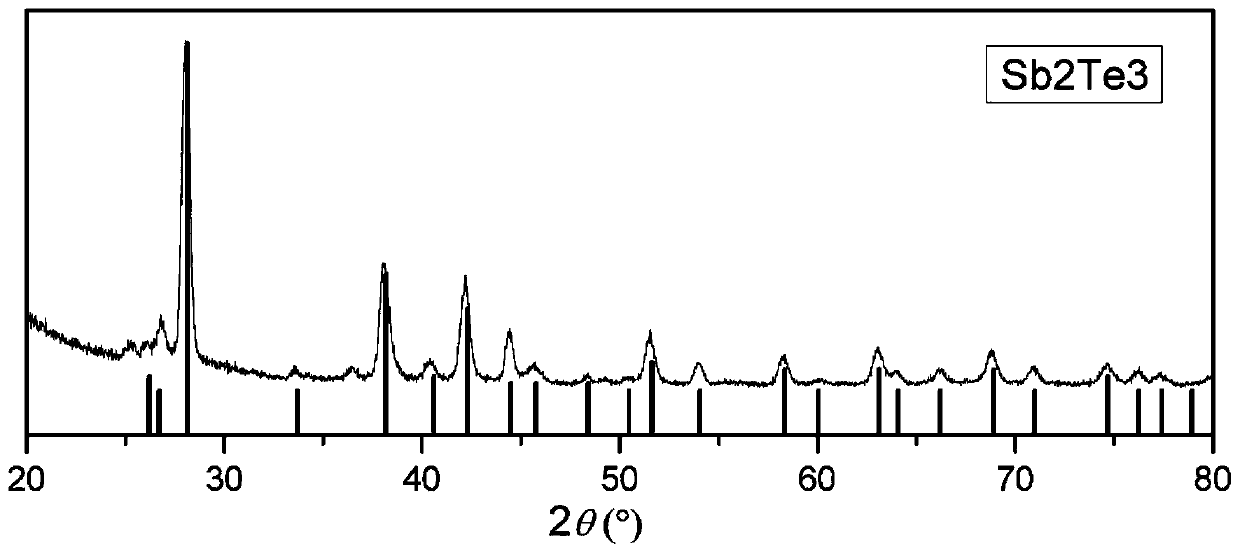

[0025] S1. Binary alloy synthesis: Under the protection of protective gas, take a certain proportion of Ge powder and Te powder, Sb grain and Te powder into the first quartz boat and the second quartz boat respectively, and put the first quartz boat and the second quartz boat The two quartz boats are respectively put into the tube furnace, heated by step-wise heating and heat preservation, and react to form GeTe alloy and Sb respectively. 2 Te 3 alloy;

[0026] S2. Pulverization and pulverization: under the protection of protective gas, the GeTe alloy and Sb 2 Te 3 The alloy is crushed by a pulverizer to obtain GeTe and Sb 2 Te 3 Alloy powder;

[0027] S3. Homogeneous mixing: take the GeTe alloy powder and Sb crushed in S2 in proportion 2 Te 3 The alloy powder is mixed in the PV barrel, and then put a certain amount of zirconium ball...

Embodiment 1

[0041] Germanium powder (Ge) with a purity of 4N, antimony particles (Sb) with 5N, and tellurium powder (Te) with 5N were prepared. Calculated according to the stoichiometric ratio Ge:Te=1:1 and Sb:Te=2:3, considering that Te will be volatilized and lost during the heating reaction, based on the theoretical calculation of materials, Te is slightly excessive.

[0042] Firstly, a protective gas-nitrogen was introduced into the tube furnace at an air flow rate of 10 L / min for 30 minutes to remove the air in the tube furnace, and 108.84 g of germanium and 192.66 g of tellurium were weighed with an electronic balance with an accuracy of 0.01 g. 233.34g antimony and 369.66g tellurium, put 108.84g germanium and 192.66g tellurium into the first quartz boat, put 233.34g antimony and 369.66g tellurium into the second quartz boat, put the first quartz boat into the tube furnace , and continue to feed nitrogen into the tube furnace at a gas flow rate of 10 L / min for 30 min.

[0043] In t...

Embodiment 2

[0050] Germanium powder (Ge) with a purity of 4N, antimony particles (Sb) with 5N, and tellurium powder (Te) with 5N were prepared. Calculated according to the atomic ratio Ge:Te=1:1 and Sb:Te=2:3, considering that Te will be volatilized and lost during the heating reaction, based on the theoretical calculation of materials, Te is slightly excessive.

[0051] Firstly, a protective gas-nitrogen was introduced into the tube furnace at an air flow rate of 10 L / min for 30 minutes to remove the air in the tube furnace, and 90.70 g of germanium and 160.30 g of tellurium were weighed with an electronic balance with an accuracy of 0.01 g. 213.90g antimony and 338.31g tellurium, put 90.70g germanium and 160.30g tellurium into the first quartz boat, put 213.90g antimony and 338.31g tellurium into the second quartz boat, put the first quartz boat into the tube furnace , and continue to feed nitrogen into the tube furnace at a gas flow rate of 10 L / min for 30 min.

[0052] In the tube fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com