Molecular sieve-based Ce-Mn oxide porous photocatalyst, and preparation method and application thereof

A photocatalyst, molecular sieve-based technology, applied in the field of molecular sieve-based Ce-Mn oxide porous photocatalyst and its preparation, can solve problems such as limited application, and achieve the effects of inhibiting recombination, increasing concentration, and improving photocatalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

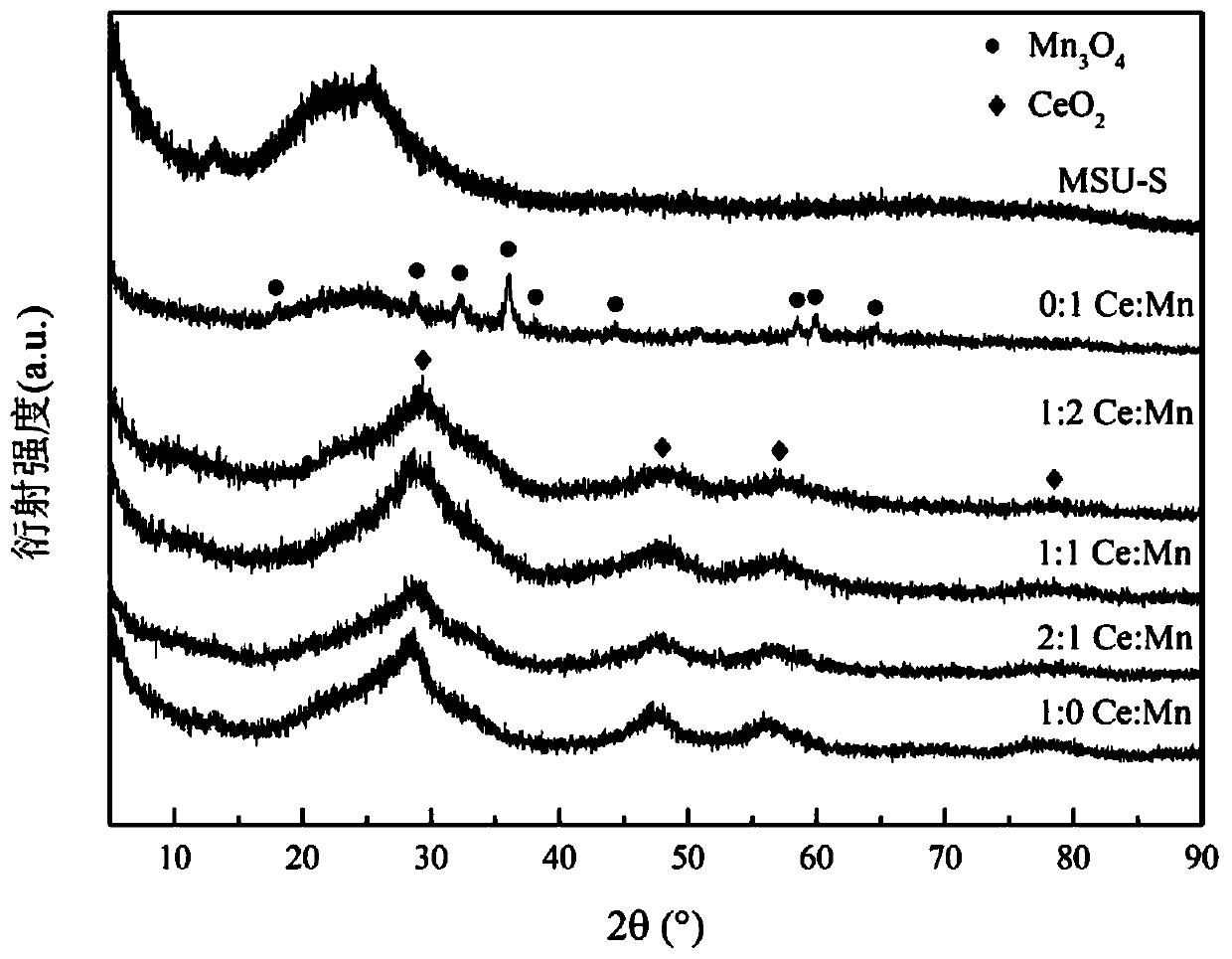

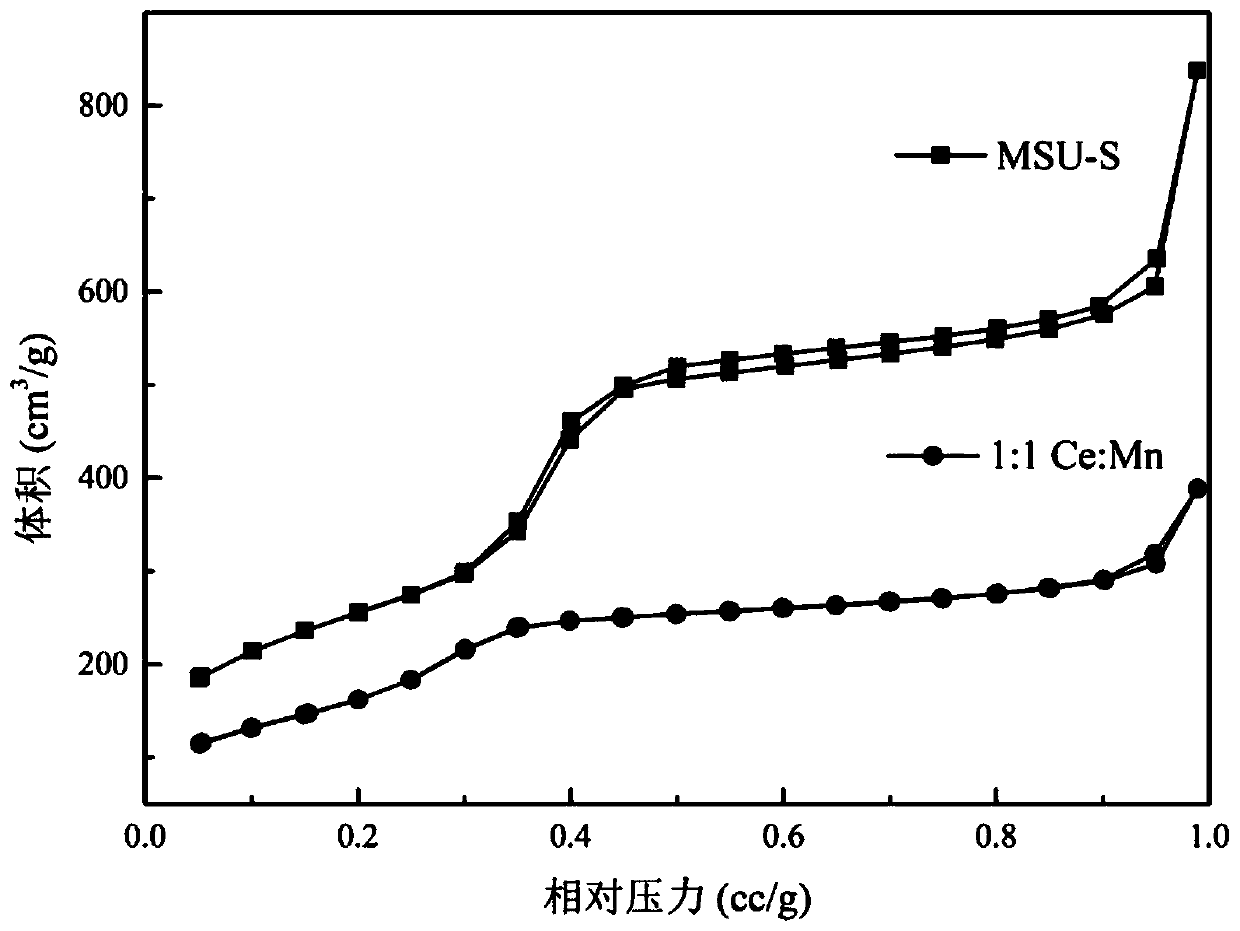

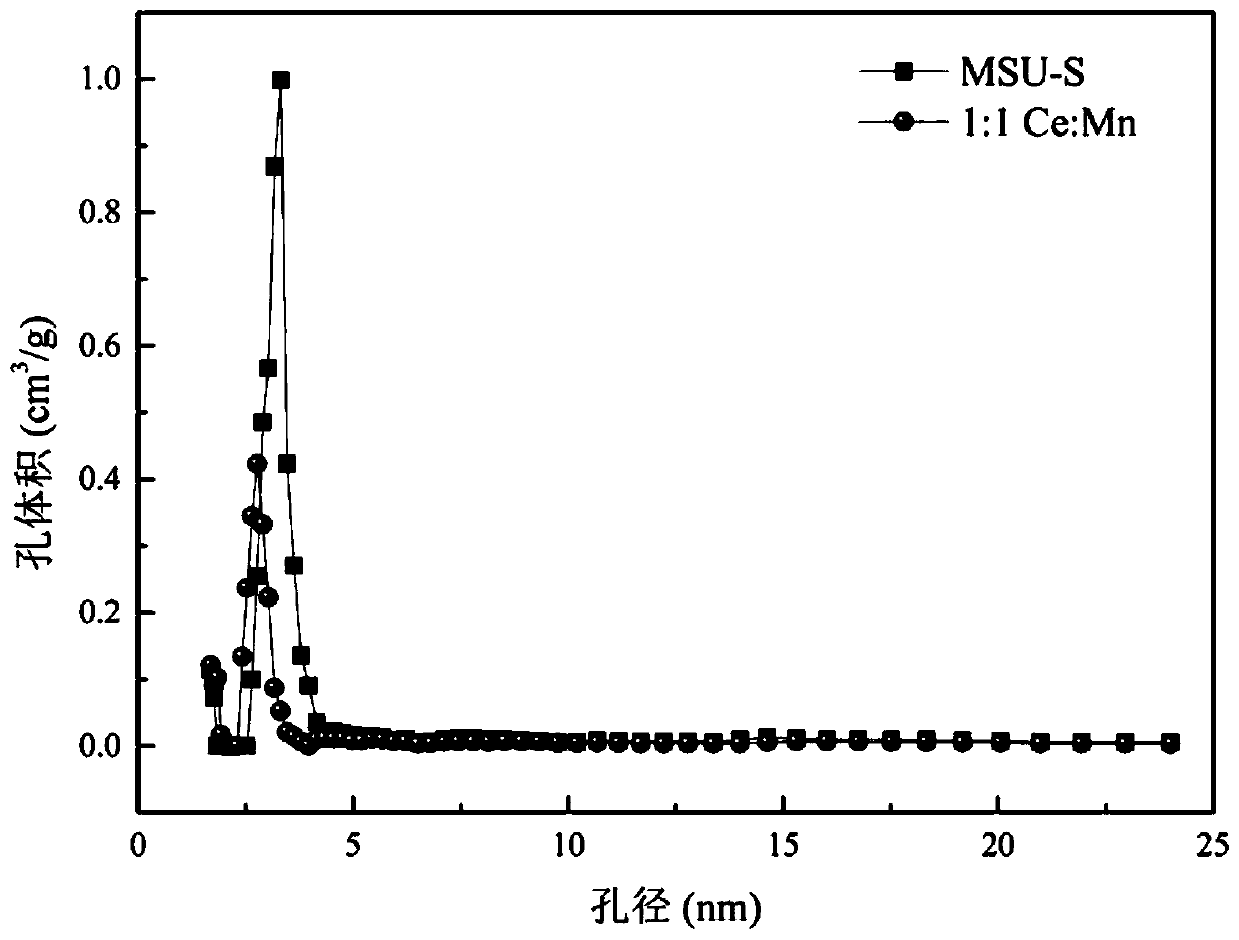

[0038] (1) Preparation of molecular sieve: After mixing 10.2 g of tetrapropylammonium hydroxide and 79 g of deionized water, 6.0 g of fumed white carbon black and 0.34 g of sodium aluminate were added in sequence. The solution was stirred at 50°C for 18h and then mixed with 9.44g CTAB (cetyltrimethylammonium bromide) for hydrothermal reaction. L (96% ethanol) NH 4 NO 3 Perform ion exchange at 80°C for 2h, and then calcinate at 550°C for 10h after drying, with a heating rate of 1°C / min.

[0039] (2) Loading of cerium oxide and manganese oxide: Weigh 1.53g of cerium acetate, 2.37g of manganese acetate, and 0.3g of molecular sieve, add them into 30ml of deionized water, heat and stir until they are completely dissolved. The obtained solution was stirred at 50°C for 12h, then ultrasonically treated for 30min, and finally solid-liquid separation was carried out by autothermal diafiltration, and the obtained solid was dried and calcined at 350°C for 2h with a heating rate of 1°C / m...

Embodiment 2

[0041] (1) Preparation of molecular sieve: After mixing 10.2 g of tetrapropylammonium hydroxide and 79 g of deionized water, 6.0 g of fumed white carbon black and 0.34 g of sodium aluminate were added in sequence. The solution was stirred at 50°C for 18h and then mixed with 9.44g CTAB (cetyltrimethylammonium bromide) for hydrothermal reaction. L (96% ethanol) NH 4 NO 3 Perform ion exchange at 80°C for 2h, and then calcinate at 550°C for 10h after drying, with a heating rate of 1°C / min.

[0042](2) Loading of cerium oxide and manganese oxide: Weigh 1.96g of cerium acetate, 1.52g of manganese acetate, and 0.3g of molecular sieve, add them into 30ml of deionized water, heat and stir until they are completely dissolved. The obtained solution was stirred at 50°C for 12h, then ultrasonically treated for 30min, and finally solid-liquid separation was performed by autothermal diafiltration, and the obtained solid was dried and calcined at 350°C for 2h with a heating rate of 1°C / min....

Embodiment 3

[0044] (1) Preparation of molecular sieve: After mixing 10.2 g of tetrapropylammonium hydroxide and 79 g of deionized water, 6.0 g of fumed white carbon black and 0.34 g of sodium aluminate were added in sequence. After the solution was stirred at 50°C for 18h, it was mixed with 9.44g CTAB (cetyltrimethylammonium bromide) for hydrothermal reaction. L (96% ethanol) NH 4 NO 3 Perform ion exchange at 80°C for 2h, and then calcinate at 550°C for 10h after drying, with a heating rate of 1°C / min.

[0045] (2) Loading of cerium oxide and manganese oxide: Weigh 2.29 g of cerium acetate, 0.88 g of manganese acetate, and 0.3 g of molecular sieve, add them into 30 ml of deionized water, heat and stir until they are completely dissolved. The obtained solution was stirred at 50°C for 12h, then ultrasonically treated for 30min, and finally solid-liquid separation was performed by autothermal diafiltration, and the obtained solid was dried and calcined at 350°C for 2h with a heating rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com