Method for producing anti-caking edible sodium chloride

A production method and technology of sodium chloride, applied in the direction of alkali metal chloride, alkali metal halide purification, etc., to achieve the effect of high industrial value, good application prospect and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

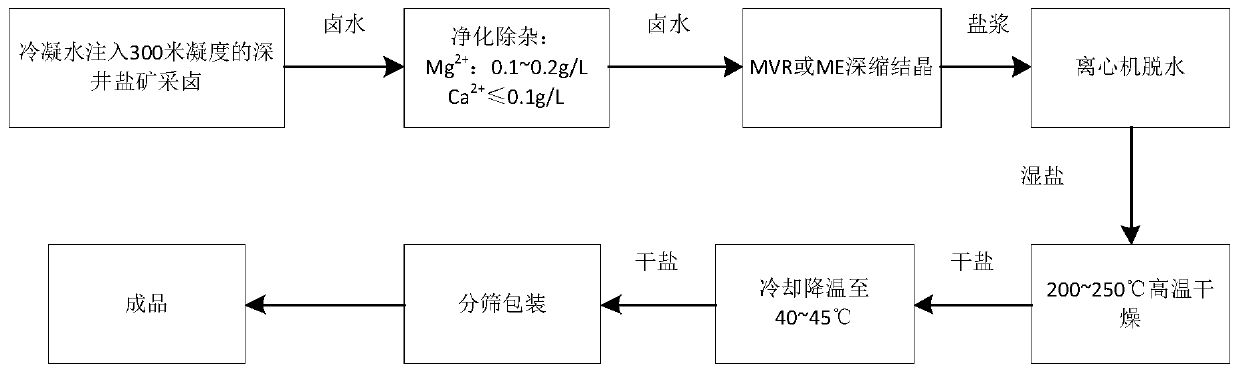

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the present invention provides a kind of production method of anti-caking edible sodium chloride, comprises the steps:

[0036](1) inject the steam condensed water that produces in the evaporation process into the deep well that the depth surpasses 300m, make the brine that sodium chloride concentration is 296g / l, the brine is transferred in the reaction mixing pool; 28% sodium carbonate solution and 28% sodium hydroxide solution by mass percentage fully react to remove calcium ions and some magnesium ions, so that the magnesium ion content in the brine is reduced to 0.16g / l, and the calcium ion content is reduced to 0.1g / l 1 or less, after sedimentation and filtration, the clear liquid enters the original brine pool to obtain refined brine;

[0037] (2) Transport the refined brine to the MVR or ME evaporator for concentration and crystallization, and discharge the system when the solid-liquid volume ratio of the salt slurry reaches 48%. The evaporation ...

Embodiment 2

[0041] Embodiment 2 of the present invention provides a kind of production method of anti-caking edible sodium chloride, comprises the steps:

[0042] (1) inject the steam condensed water produced in the evaporation process into a deep well with a depth of more than 300m to obtain brine with a sodium chloride concentration of 298g / l, and transfer the brine to the reaction mixing tank; 25% sodium carbonate solution and 25% sodium hydroxide solution by mass percentage fully react to remove calcium ions and some magnesium ions, so that the magnesium ion content in the brine is reduced to 0.12g / l, and the calcium ion content is reduced to 0.1g / l 1 or less, after sedimentation and filtration, the clear liquid enters the original brine pool to obtain refined brine;

[0043] (2) Transport the refined brine to the MVR or ME evaporator for concentration and crystallization, and discharge the salt slurry out of the system when the solid-to-liquid volume ratio reaches 42%. The evaporati...

Embodiment 3

[0047] Embodiment 3 of the present invention provides a kind of production method of anti-caking edible sodium chloride, comprises the steps:

[0048] (1) Inject the steam condensed water produced in the evaporation process into a deep well with a depth of more than 300m to obtain brine with a sodium chloride concentration of 300g / l, and transfer the brine to the reaction mixing tank; 25% sodium carbonate solution and 25% sodium hydroxide solution by mass percentage fully react to remove calcium ions and some magnesium ions, so that the content of magnesium ions in the brine is reduced to 0.1g / l, and the content of calcium ions is reduced to 0.1g / l 1 or less, after sedimentation and filtration, the clear liquid enters the original brine pool to obtain refined brine;

[0049] (2) Transfer to MVR or ME evaporator for concentration and crystallization, and discharge the system when the solid-liquid volume ratio of salt slurry reaches 40%. The evaporation crystallization temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com