A high-efficiency nitrogen and phosphorus recovery electrochemical reaction system

A technology for chemical reaction and electricity recovery, applied in chemical instruments and methods, electrolysis components, electrolysis process, etc., can solve the problems of slow formation rate of struvite and insufficient crystallization and precipitation of struvite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

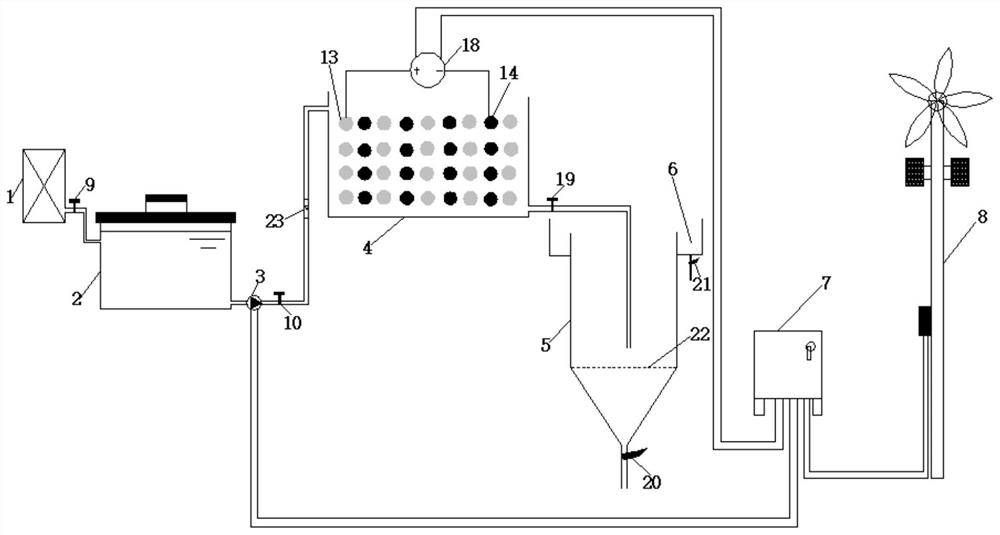

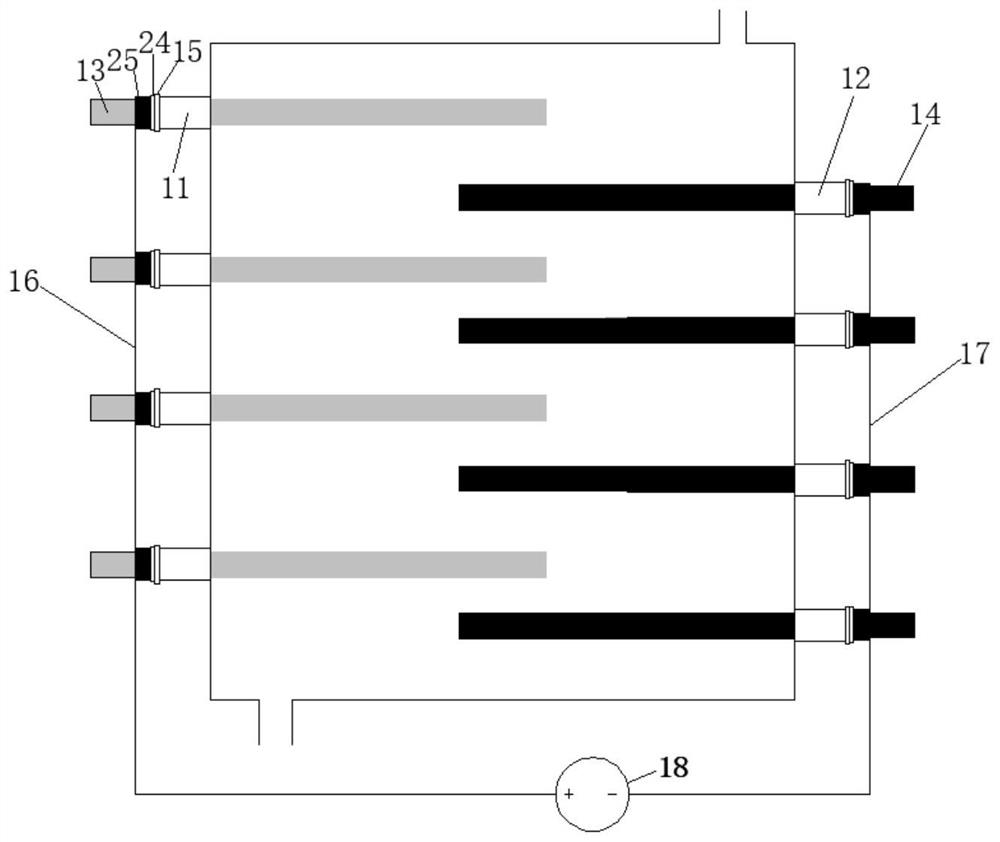

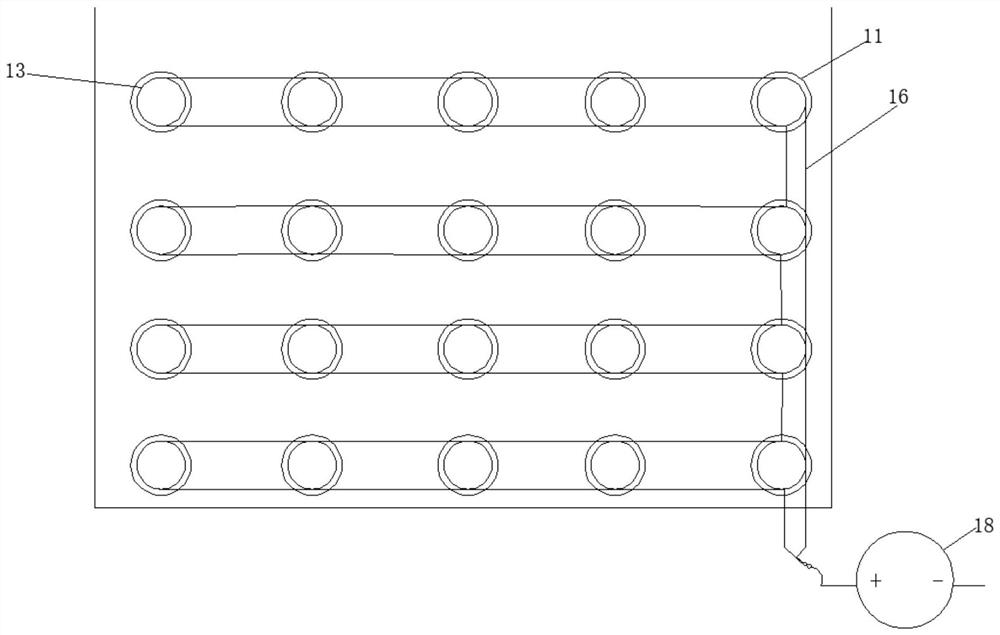

[0045] figure 1 It is a front sectional view of an efficient nitrogen and phosphorus recovery electrochemical reaction system of the present invention. figure 2 It is a top view of the electrolytic reaction cell in the high-efficiency nitrogen and phosphorus recovery electrochemical reaction system of the present invention. A high-efficiency nitrogen and phosphorus recovery electrochemical reaction system of the present invention includes a pretreatment unit 1, a feed box 2, a lift pump 3, an electrolytic reaction tank 4, a struvite sedimentation tank 5 and a liquid storage tank 6;

[0046] The pretreatment unit 1 is connected to the first valve 9 through a pipeline, and the first valve 9 is connected to the feed box 2 through a pipeline, and the pretreatment unit 1 is used to transport the feed liquid to the feed through the first valve 9. In the box 2; the pretreatment unit 1 adopts the microfiltration unit as the main body, and puts fillers and other filter adsorption sub...

Embodiment 2

[0053] A high-efficiency nitrogen and phosphorus recovery electrochemical reaction system of the present invention includes a pretreatment unit 1, a feed box 2, a lift pump 3, an electrolytic reaction tank 4, a struvite sedimentation tank 5, a liquid storage tank 6, a distribution box 7 and Wind-solar hybrid power generation system 8;

[0054] The pretreatment unit 1 is connected to the first valve 9 through a pipeline, and the first valve 9 is connected to the feed box 2 through a pipeline, and the pretreatment unit 1 is used to transport the feed liquid to the feed through the first valve 9. In the box 2; the pretreatment unit 1 adopts the microfiltration unit as the main body, and puts fillers and other filter adsorption substances in the pretreatment unit 1 to pretreat the feed wastewater, and the pretreated stock solution passes through the first valve 9 into feed box 2;

[0055] The lift pump 3 is connected to the second valve 10 through a pipeline, and the second valve...

Embodiment 3

[0064] A high-efficiency nitrogen and phosphorus recovery electrochemical reaction system of the present invention includes a pretreatment unit 1, a feed box 2, a lift pump 3, an electrolytic reaction tank 4, a struvite sedimentation tank 5, a liquid storage tank 6, a distribution box 7 and Wind-solar hybrid power generation system 8;

[0065] The pretreatment unit 1 is connected to the first valve 9 through a pipeline, and the first valve 9 is connected to the feed box 2 through a pipeline, and the pretreatment unit 1 is used to transport the feed liquid to the feed through the first valve 9. In the box 2; the pretreatment unit 1 adopts the microfiltration unit as the main body, and puts fillers and other filter adsorption substances in the pretreatment unit 1 to pretreat the feed wastewater, and the pretreated stock solution passes through the first valve 9 into feed box 2;

[0066] The lift pump 3 is connected to the second valve 10 through a pipeline, and the second valve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com