System and process for recycling and zero emission of ammonium sulfate-containing wastewater

An ammonium sulfate, recycling technology, applied in the field of hazardous waste recycling, can solve the problems of secondary pollution, high operating costs, large consumption of medicines, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

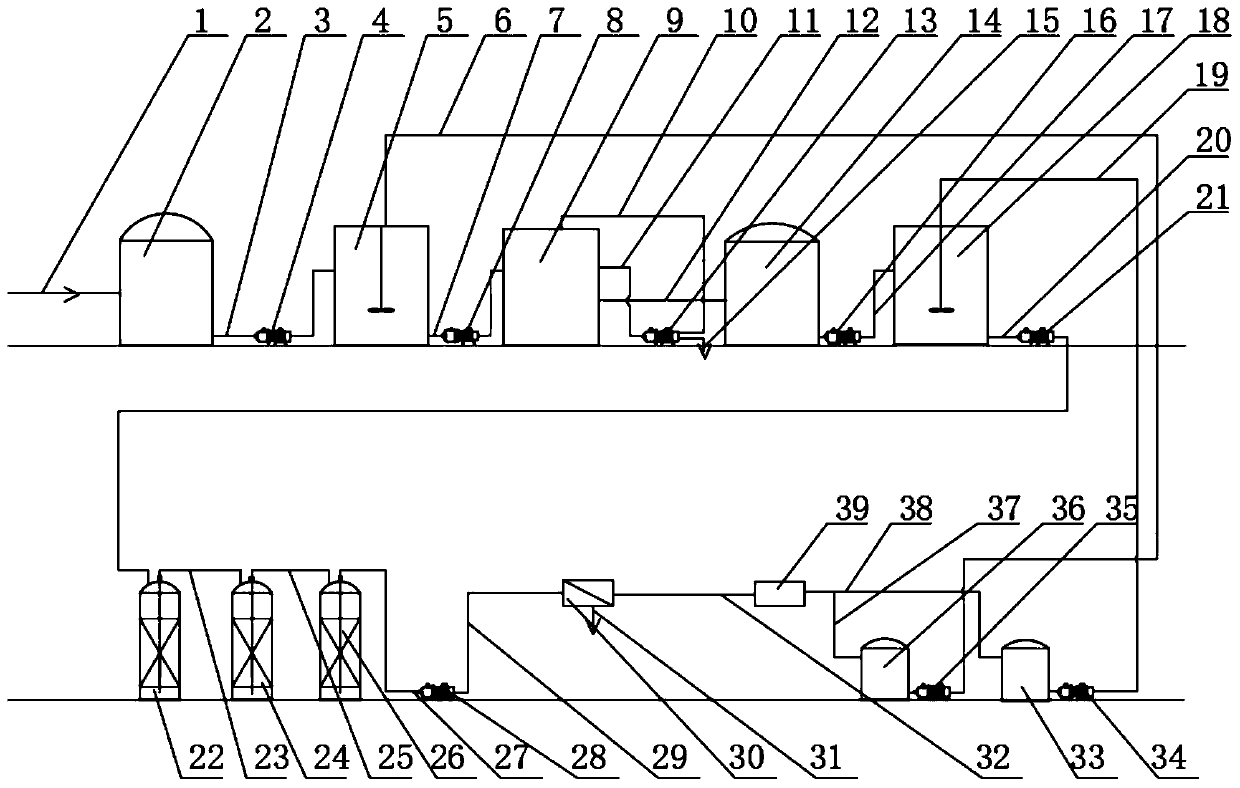

Image

Examples

Embodiment

[0036] There is a stream of wastewater, the main pollutant is ammonia nitrogen, other pollutants (such as organic matter) are less, and the water quality is relatively "clean"; its composition is pH=2.5, (NH 4 ) 2 SO 4 =25% (mass concentration), this wastewater needs to be treated to reach the "clear sewage" discharge standard, and needs to be processed as follows:

[0037] Step 1: After the ammonium sulfate wastewater is adjusted to pH by the evaporation pretreatment system 5, it is then subjected to evaporation treatment. The evaporated concentrated water is lifted to the centrifuge for crystallization treatment through the discharge pump to obtain ammonium sulfate crystallization products, and the mother liquor produced by centrifugation is re-entered. Evaporation and concentration are carried out in the evaporator 9, and the steam generated by the evaporator 9 is cooled by the steam storage tank 14. The water quality concentration of step 1 effluent is pH=5.1, (NH 4 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com