Gallium arsenide single crystal growth device and growth method

A growth device and growth method technology, applied in the field of crystal growth, can solve the problems of inability to grow single crystals, long growth cycle, high cost, reduce material loss, impurity pollution, good single crystal performance and quality, and reduce processing and cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

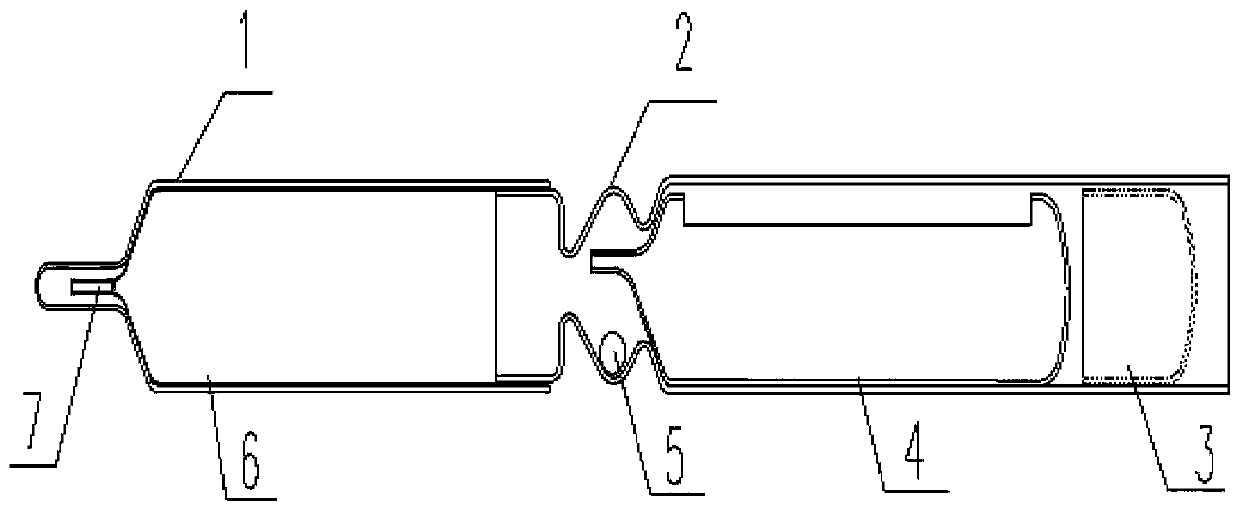

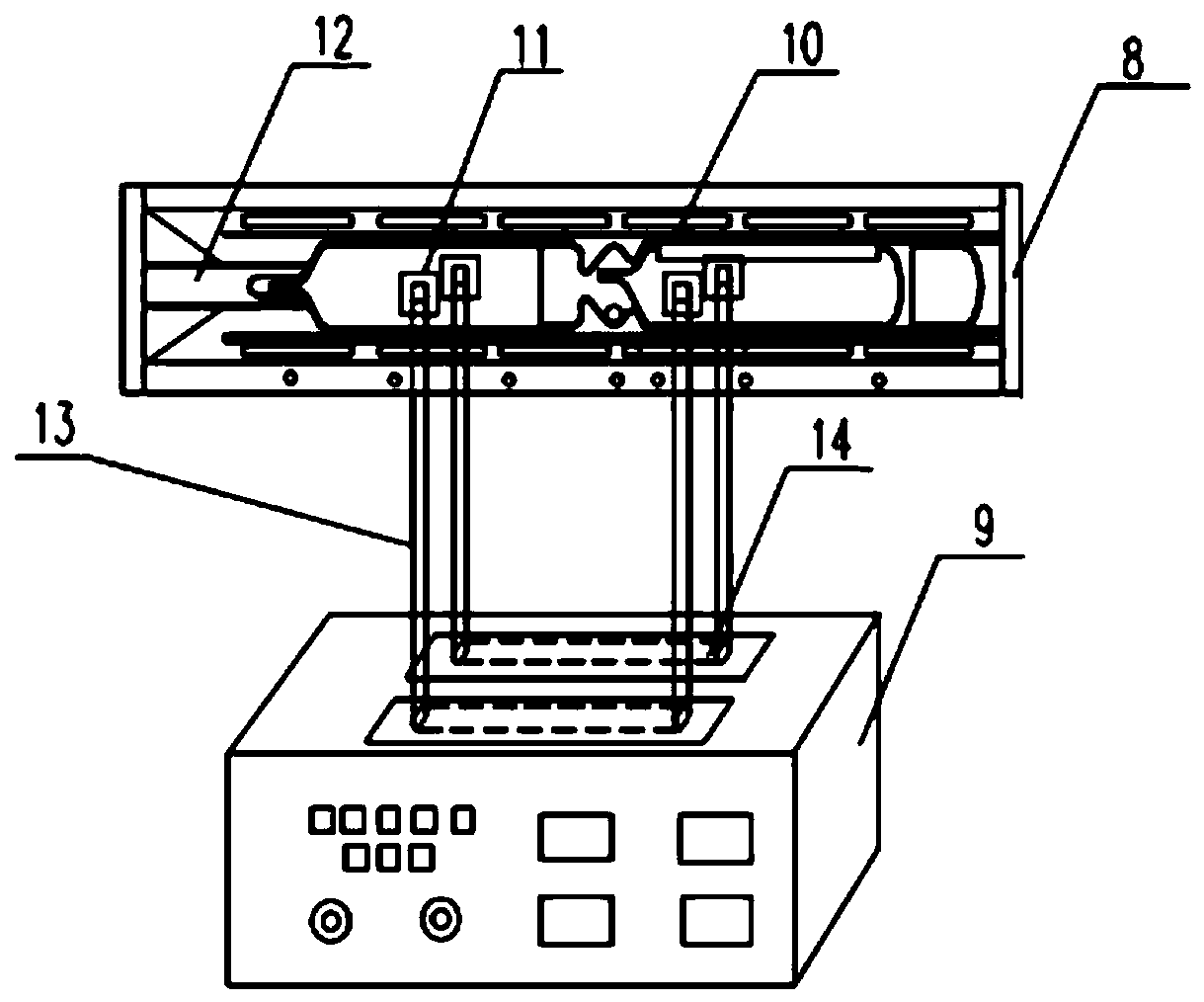

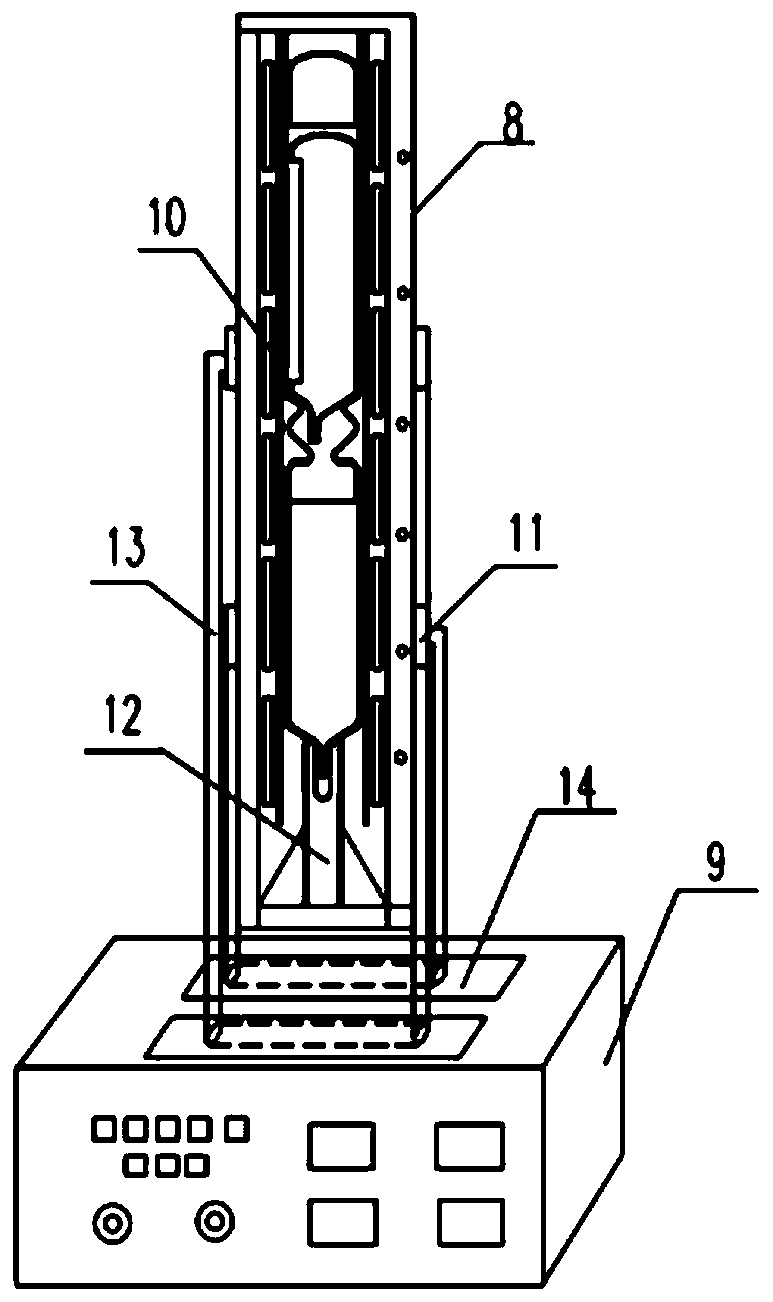

[0042] An embodiment of the gallium arsenide single crystal growth method of the present invention uses the gallium arsenide single crystal growth device of the present invention for single crystal growth.

[0043] The specific structure of the gallium arsenide single crystal growth device of the present invention is: including quartz tube parts, single crystal furnace body, single crystal furnace frame, controller, heating wire, quartz support tube, furnace lifting rod, lifting rod slideway , the quartz tube part is set in the body of the single crystal furnace, the body of the single crystal furnace is placed on the frame of the single crystal furnace, the slideway of the lifting rod is set on the upper part of the controller, and the controller slides through the lifting rod The road is connected with the furnace body lifting rod, and the furnace body lifting rod is connected with the single crystal furnace body through the single crystal furnace frame, and the single crysta...

Embodiment 2

[0060] An embodiment of the gallium arsenide single crystal growth method of the present invention uses the same gallium arsenide single crystal growth device as in embodiment 1.

[0061] The method for growing a gallium arsenide single crystal in this embodiment includes the following steps:

[0062] (1) Place the gallium arsenide seed crystal in the PBN crucible seed crystal cavity, and then put the PBN crucible into the single crystal quartz tube;

[0063] (2) Butt the head of the W-shaped polycrystalline quartz tube with the tail of the single crystal quartz tube, and then weld the two together with a hydrogen-oxygen flame;

[0064] (3) load 6N arsenic into the welded monocrystalline quartz tube PBN crucible, weight is 5.75Kg, put 40g boron oxide and doped Si sheet into the W-shaped position of W-shaped polycrystalline quartz tube;

[0065] (4) 6N gallium with a weight of 5.3Kg is packed in a quartz boat, then put into a W-shaped polycrystalline quartz tube, and then put ...

Embodiment 3

[0076] An embodiment of the gallium arsenide single crystal growth method of the present invention uses the same gallium arsenide single crystal growth device as in embodiment 1.

[0077] The method for growing a gallium arsenide single crystal in this embodiment includes the following steps:

[0078] (1) Place the gallium arsenide seed crystal in the PBN crucible seed crystal cavity, and then put the PBN crucible into the single crystal quartz tube;

[0079] (2) Butt the head of the W-shaped polycrystalline quartz tube with the tail of the single crystal quartz tube, and then weld the two together with a hydrogen-oxygen flame;

[0080] (3) load 6N arsenic into the welded single crystal quartz tube PBN crucible, weight is 6.25Kg, put 40g boron oxide and doped Si sheet into the W-shaped position of W-shaped polycrystalline quartz tube;

[0081] (4) 6N gallium with a weight of 5.8Kg is packed in a quartz boat, then put into a W-shaped polycrystalline quartz tube, and then put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com