Composition for forming coating film for foreign matter removal use

A technology of composition and film coating, which is applied in the preparation of detergent mixture composition, detergent composition, non-surface active detergent composition, etc., can solve the problems of incomplete removal, etc., and achieve the reduction of defects and the improvement of yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

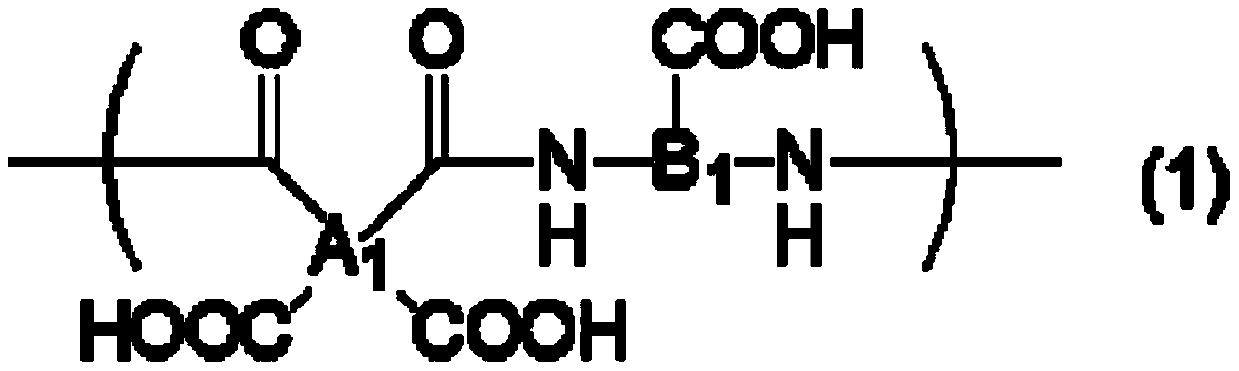

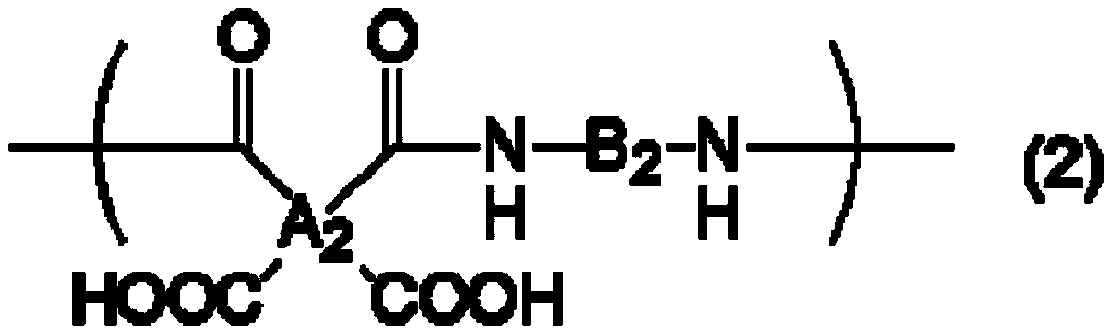

Method used

Image

Examples

Embodiment 1

[0147] (Synthesis of polyamic acid)

[0148] By mixing 4.36g of pyromellitic dianhydride, 1.19g of diaminobenzoic acid, and 4.26g of 2,2-bis(3-amino-4-toluoyl)hexafluoropropane in 55.6g of propylene glycol monomethyl ether at 60 The reaction was carried out at °C for 25 hours to obtain a solution [A] containing a polyamic acid.

[0149] (Synthesis of light-absorbing compounds)

[0150] By making 19.0g of 3,7-dihydroxy-2-naphthoic acid, 10g of tris(2,3-epoxypropyl)isocyanurate, and 0.552g of benzyltriethylammonium chloride in 118g of cyclohexanone The reaction was carried out at 130° C. for 24 hours to obtain a solution [a] containing a light-absorbing compound.

[0151] (Preparation of coating film-forming composition for foreign matter removal)

[0152] Add 4.38 g of solution [a] containing a light-absorbing compound, 0.630 g of tris(2,3-epoxypropyl)isocyanurate, and propylene glycol monomethyl ether to 14.0 g of solution [A] containing polyamic acid 52.3 g and 67.5 g of ...

Embodiment 2

[0160] (Preparation of coating film-forming composition for foreign matter removal)

[0161] To 14.0 g of the polyamic acid solution [A] used in Example 1, 4.38 g of the solution [a] containing a light-absorbing compound used in Example 1 and tris(2,3-epoxypropyl)isocyanurate were added Ester 0.630g, 2,4,6-tris(4-hydroxyphenylmethyl)-1,3-benzenediol 0.0450g, propylene glycol monomethyl ether 52.8g, propylene glycol monomethyl ether acetate 67.5g It stirred at room temperature for 30 minutes, and prepared the solution [2] of the composition for coating film formations used for foreign material removal.

[0162] (Evaluation of Coating Film Forming Composition for Foreign Matter Removal)

[0163] The solution [2] of the coating film-forming composition for foreign matter removal was coated on a silicon wafer substrate using a spinner, and fired at 200° C. for 60 seconds on a hot plate to form a film with a film thickness of 40 nm. Coating film for foreign matter removal. The o...

Embodiment 3

[0169] (Synthesis of polyamic acid)

[0170] By mixing 4.36g of pyromellitic dianhydride, 0.89g of diaminobenzoic acid, and 4.97g of 2,2-bis(3-amino-4-toluoyl)hexafluoropropane in 55.6g of propylene glycol monomethyl ether at 60 The reaction was carried out at °C for 25 hours to obtain a solution [B] containing a polyamic acid.

[0171] (Preparation of coating film-forming composition for foreign matter removal)

[0172] 4.38 g of the solution [a] containing the light-absorbing compound used in Example 1 and 0.630 g of tris(2,3-epoxypropyl)isocyanurate were added to 14.0 g of the solution [B] containing polyamic acid , 52.4 g of propylene glycol monomethyl ether, and 67.5 g of propylene glycol monomethyl ether acetate were stirred at room temperature for 30 minutes to prepare a solution [3] of a coating film-forming composition for foreign matter removal.

[0173] (Evaluation of Coating Film Forming Composition for Foreign Matter Removal)

[0174] The solution [3] of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com