Core-shell SiC@C catalyst for microwave-assisted catalytic depolymerization of solid waste and preparation method of catalyst

A solid waste and microwave-assisted technology, applied in the field of catalytic conversion of waste resources, can solve the problems that the efficiency of microwave absorption and heat transfer is not as good as that of polar medium materials, and affect the catalytic conversion efficiency of catalysts, etc., and achieve efficient depolymerization of microwave absorption enhanced heat transfer and catalysis , promote high-efficiency and high-value utilization, and improve the effect of targeted regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a core-shell SiC@C catalyst for microwave-assisted catalytic depolymerization of solid waste proposed by the present invention comprises the following steps:

[0032] (1) Put SiC in a reaction vessel, add 0.01mol / L surfactant solution, and treat it at an ultrasonic frequency of 30-50kHz for 20min to form a suspension. The mass ratio of surfactant solution to SiC is (8-12):1. The surfactant is any one of sodium dodecylsulfate (SDS), sodium cetylsulfonate, sodium dodecylbenzenesulfonate, triethanolamine dodecylsulfate.

[0033] (2) Add resorcinol to the suspension in step (1), stir for 30 to 50 minutes to dissolve the resorcinol completely, then add in turn the NaOH solution with a mass fraction of 10% and the formaldehyde with a mass fraction of 37% solution, and then stirred and reacted at 25~30°C for 6~8h. The mass ratio of resorcinol to SiC is (0.2~3):1, the mass ratio of 10% NaOH solution to resorcinol is (1~3):1, and the mass ratio of formal...

Embodiment 1

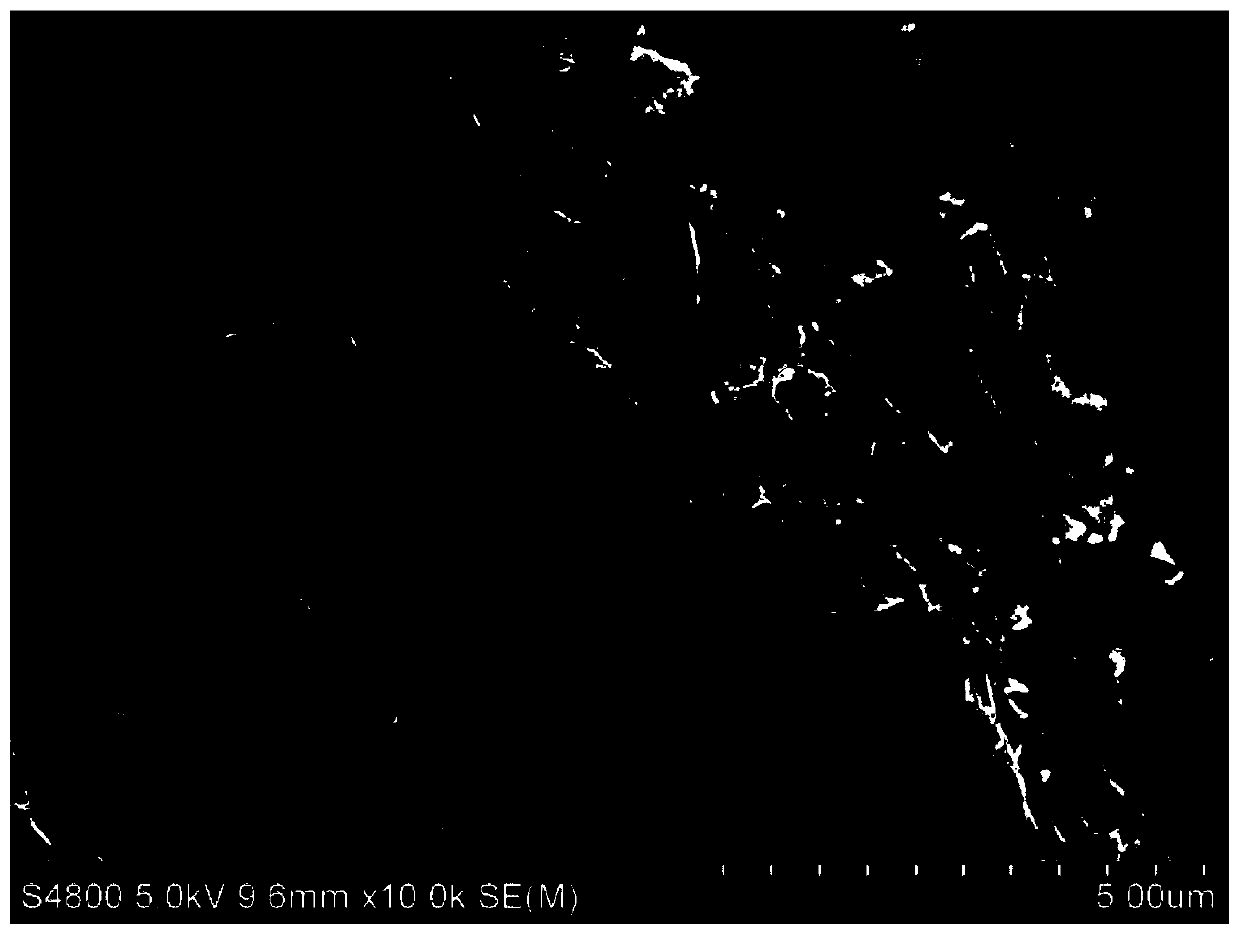

[0040] Put 1 g of SiC in a reaction vessel, add 8 g of sodium dodecyl sulfate solution with a concentration of 0.01 mol / L, and treat it at an ultrasonic frequency of 30 kHz for 20 min to form a suspension. Then add 0.2g resorcinol in the suspension, stir for 30min, make the resorcinol dissolve completely, then add the NaOH solution 0.2g that the mass fraction is 10%, and the formaldehyde solution 0.1g that the mass fraction is 37%, then The reaction was stirred at 25 °C for 8 h. The obtained product was washed once with ethanol and once with deionized water, and then vacuum freeze-dried to obtain the SiC@RF catalyst carrier precursor. Take 1g of the obtained SiC@RF catalyst support precursor, 2 In an atmosphere with a flow rate of 10mL / min and a water vapor flow rate of 0.01mL / min, the temperature was raised to 500°C at a rate of 6°C / min, and then kept for 6h to obtain a SiC@C catalyst support. figure 1 Shown is the SEM image of the SiC@C catalyst carrier. It can be seen tha...

Embodiment 2

[0042] Put 1 g of SiC in a reaction vessel, add 10 g of sodium hexadecylsulfonate solution with a concentration of 0.01 mol / L, and treat it at an ultrasonic frequency of 35 kHz for 20 min to form a suspension. Then add 1g resorcinol in the suspension, stir for 35min, make the resorcinol dissolve completely, then add successively the NaOH solution 1.5g that the mass fraction is 10%, the formaldehyde solution 1g that the mass fraction is 37%, then in 28 The reaction was stirred at ℃ for 7.5h. The obtained product was washed once with ethanol and twice with deionized water, and then spray-dried to obtain the SiC@RF catalyst carrier precursor. Take 1g of the obtained SiC@RF catalyst support precursor, 2 In an atmosphere with a flow rate of 40mL / min and a water vapor flow rate of 0.2mL / min, the temperature was raised to 650°C at a rate of 8°C / min and kept for 5.5h to obtain a SiC@C catalyst support. The SiC@C catalyst support was added to a concentration of 1 wt% CoCl 2 solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com