Tubular g-C3N4/CuS/Cu2S nano composite material and preparation method and application thereof

A nanocomposite material, g-c3n4 technology, applied in the field of materials, can solve the problems of high energy consumption, secondary pollution, incomplete treatment, etc., and achieve the effect of uniform distribution, large specific surface area, and favorable separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

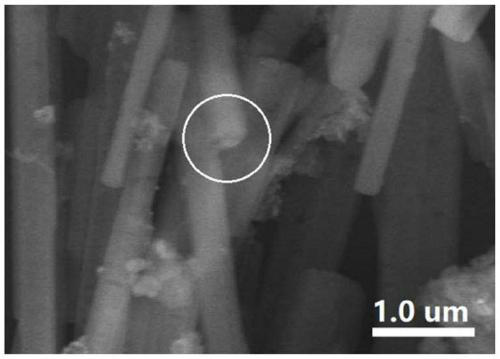

[0036] Tubular g-C of the present invention 3 N 4 / CuS / Cu 2 The preparation method of S nanocomposite material, comprises the following steps:

[0037] (1) will prepare g-C 3 N 4 The raw materials are thermally polycondensed under static atmosphere to obtain g-C 3 N 4 Block shape;

[0038] Among them, the preparation of g-C 3 N 4 The raw material is a mixture of one or more of urea, melamine, dicyandiamide or cyanamide; the conditions for thermal polycondensation are: the temperature is raised to 350-750°C at a heating rate of 1-8°C / min, and the heat preservation 2~5h;

[0039] (2) the g-C obtained in step (1) 3 N 4 Bulk shape is thermally exfoliated under air atmosphere to obtain light yellow g-C 3 N 4 Nanosheets;

[0040] Among them, the conditions for thermal peeling are: heating at a heating rate of 1-15°C / min to a temperature of 400-750°C, and holding for 2-6 hours;

[0041] (3) the g-C obtained in step (2) 3 N 4 The nanosheets were calcined in a tube fur...

Embodiment 1

[0054] (1) Weigh 7g of dicyandiamide and add it to an alumina crucible with a lid. Under air atmosphere conditions, heat up to 350°C through a muffle furnace at a heating rate of 1°C / min, and keep it warm for 1h to obtain a yellow powder sample as g-C 3 N 4 Block shape;

[0055] (2) put g-C 3 N 4 The block is spread on the bottom of the uncovered ceramic ark, and under the condition of air atmosphere, the temperature is raised to 400°C through the muffle furnace at a heating rate of 1°C / min, and kept for 2h, and the obtained light yellow powder sample is g-C 3 N 4 Nanosheets;

[0056] (3) will get g-C 3 N 4 The nanosheets were placed in a tube furnace, fed with nitrogen, heated to 250°C at a heating rate of 5°C / min for calcination, and kept for 5 minutes to obtain a yellow powder;

[0057] (4) Take out the yellow powder and place it in an ice bath for 5 minutes to obtain g-C 3 N 4 nanotube;

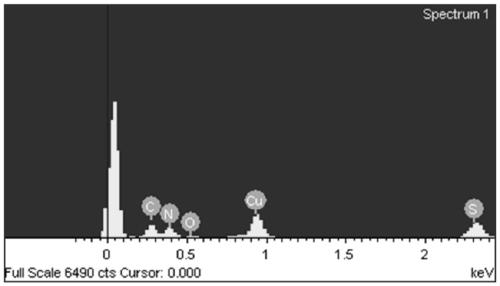

[0058] (5) the resulting g-C 3 N 4 nanotubes and 0.7 g copper sulfate pen...

Embodiment 2

[0062] Steps (1)-(4) of the present embodiment are the same as embodiment 1, and the follow-up steps are as follows:

[0063] 1.0g copper chloride (CuCl 2 ) into 100mL ethanol, then add g-C 3 N 4 The nanotubes were sonicated for 50 min. Take 1.0g sodium sulfide (Na 2 S) Dissolve in ethanol and sonicate for 50 minutes, mix the two dispersions, heat in a water bath at 90°C and stir vigorously for 4 hours; centrifuge at 7000r / min after the reaction, and dry the obtained precipitate at 60°C to obtain a tubular g-C 3 N 4 / CuS / Cu 2 S nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com