A kind of preparation method of high-purity gliclazide intermediate p-toluenesulfonylurea

A technology of toluenesulfonylurea and crystals, which is applied in the field of pharmaceutical chemical synthesis, can solve the problems of restricting the production and development of toluenesulfonylurea products, the purity is only 98%, and the product quality is low, achieving mild conditions, easy storage, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

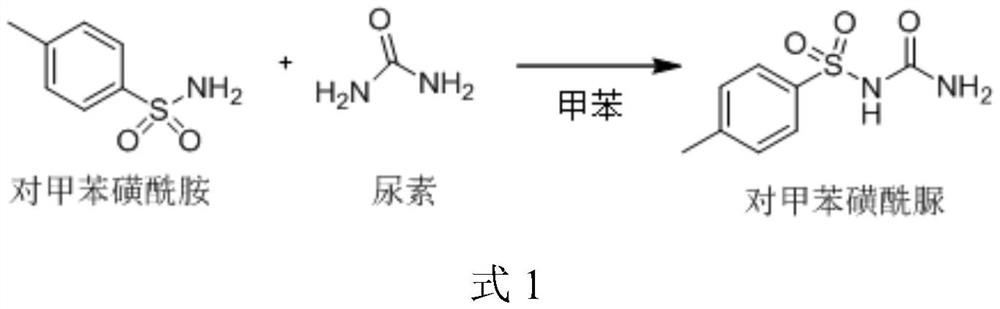

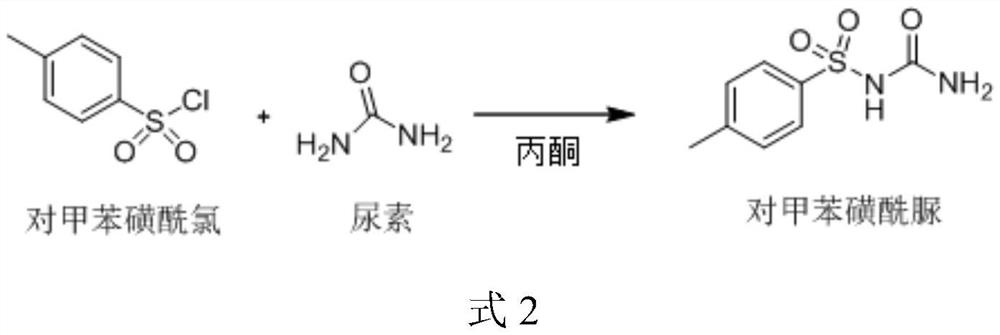

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of simple and convenient preparation method of p-toluenesulfonylurea, comprises the steps:

[0030] First fill the 3000L stainless steel reactor with nitrogen to replace the air in it, then add p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.) (197kg, 1000mol) and toluene (1000L), stir and cool down to -5~5℃ , slowly filled with ammonia gas (136kg, 8000mol, about 0.6MPa), white solid precipitated out after 4 hours of heat preservation reaction, slowly emptied (absorbed with 1% hydrochloric acid solution), replaced with nitrogen, stopped refrigeration, and slowly heated up to 25-30 ℃, keep warm for 4 hours, filter, wash with water until the pH is about 7, and obtain the crude product of p-toluenesulfonylurea.

[0031] Then add the crude product of p-toluenesulfonylurea into a 3000L reaction kettle, then add 2000L of acetonitrile / water (volume ratio: 1:1), heat to 80±5°C, reflux for 1h, program cooling (10°C / h), Lowered to below 20°C, centrifuged...

Embodiment 2

[0037] A kind of simple and convenient preparation method of p-toluenesulfonylurea, comprises the steps:

[0038] First fill the 3000L stainless steel reactor with nitrogen to replace the air in it, then add p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.) (200kg, 1015mol) and toluene (1015L), stir and cool down to -5~5℃ , slowly filled with ammonia gas (86.3kg, 5075mol, about 0.6MPa), white solid precipitated out after 4 hours of heat preservation reaction, slowly emptied (absorbed with 1% hydrochloric acid solution), replaced with nitrogen, stopped refrigeration, and slowly heated up to 25~ Keep warm at 30°C for 4 hours, filter, and wash with water until the pH is about 7 to obtain the crude product of p-toluenesulfonylurea.

[0039] Then add the crude p-toluenesulfonylurea into a 3000L reaction kettle, then add 2030L of acetonitrile / water (volume ratio: 1:1), heat to 80±5°C, reflux for 1h, program cooling (10°C / h), Lowered to below 20°C, centrifuged and ...

Embodiment 3

[0041] A kind of simple and convenient preparation method of p-toluenesulfonylurea, comprises the steps:

[0042] First fill the 3000L stainless steel reactor with nitrogen to replace the air in it, then add p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.) (191kg, 970mol) and toluene (970L), stir and cool down to -5~5℃ , slowly filled with ammonia gas (247kg, 14550mol, about 0.6MPa), white solid precipitated out after 4 hours of heat preservation reaction, slowly emptied (absorbed with 1% hydrochloric acid solution), replaced with nitrogen, stopped refrigeration, and slowly heated up to 25-30 ℃, keep warm for 4 hours, filter, wash with water until the pH is about 7, and obtain the crude product of p-toluenesulfonylurea.

[0043]Then add the crude p-toluenesulfonylurea into a 3000L reaction kettle, then add 1940L of acetonitrile / water (volume ratio: 1:1), heat to 80±5°C, reflux for 1h, program cooling (10°C / h), Lowered to below 20°C, centrifuged and dried to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com