Method for preparing humic acid from tail vegetable through treated by wet hydrolysis and application

A technology of humic acid and tail vegetables, which is applied in the field of resource utilization of tail vegetables, can solve the problems of low fertilizer utilization rate of tail vegetables, disadvantages of tail vegetables, and impact on traffic, etc., so as to improve resource utilization and development level, Decomposition time is short and the effect of prolonging the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing humic acid by wet-decomposing tail vegetables, the steps are as follows:

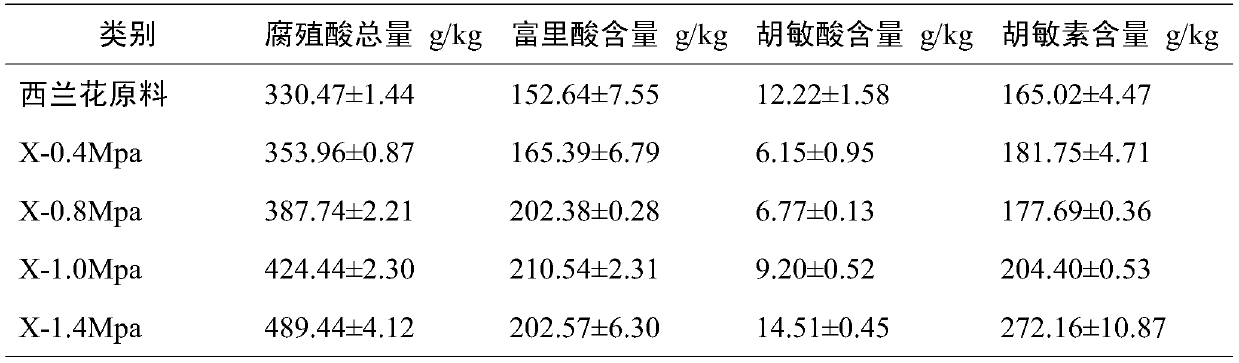

[0036] The old broccoli stems were selected and cut into 1cm×1cm×1cm blocks with an initial moisture content of 89.16%, and 4% of the total mass of the old broccoli stems was added with ammonium chloride for presoaking for 12 hours. The processed tail vegetables were placed in a wet decomposition reactor to carry out the wet decomposition reaction, the reaction temperature was 198° C., and the reaction time was 30 minutes. After the reaction is finished, the pressure in the reactor is quickly released, and the humified broccoli stem material is sprayed into the collection tank. The yield of the total humic acid obtained from the wet decomposition material was 46.72%. Add mass fraction 1% NaOH solution to the wet decomposition material and let it stand for extraction for 24 hours. After vacuum filtration for solid-liquid separation, the obtained solid extraction residue aft...

Embodiment 2

[0041] A method for preparing humic acid by wet-decomposing tail vegetables, the steps are as follows:

[0042] Select bitter gourd vines and cut them to a length of 3-5 cm, adjust the water content to 30%, add 2% sulfuric acid to the total mass of the bitter gourd vines for presoaking for 12 hours. The processed tail vegetables were placed in a wet decomposition reactor to carry out the wet decomposition reaction, the reaction temperature was 160° C., and the reaction time was 1 h. After the reaction is over, the pressure in the reactor is quickly released, and the humified balsam pear vine is sprayed into the collection tank. The total humic acid yield of the obtained wet decomposition material is 42.01%. After the temperature dropped to normal temperature, 1% NaOH solution was added and left to extract for 24 hours. After vacuum filtration for solid-liquid separation, the obtained solid extraction residue was dried with a yield of 3.22%, which was the dry product of humin....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com