Air energy cold storage phase-change material and preparation method thereof

A technology of phase change materials and air energy, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as thermal conductivity and packaging leakage, and achieve high stability, simple preparation process, and easy production and packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

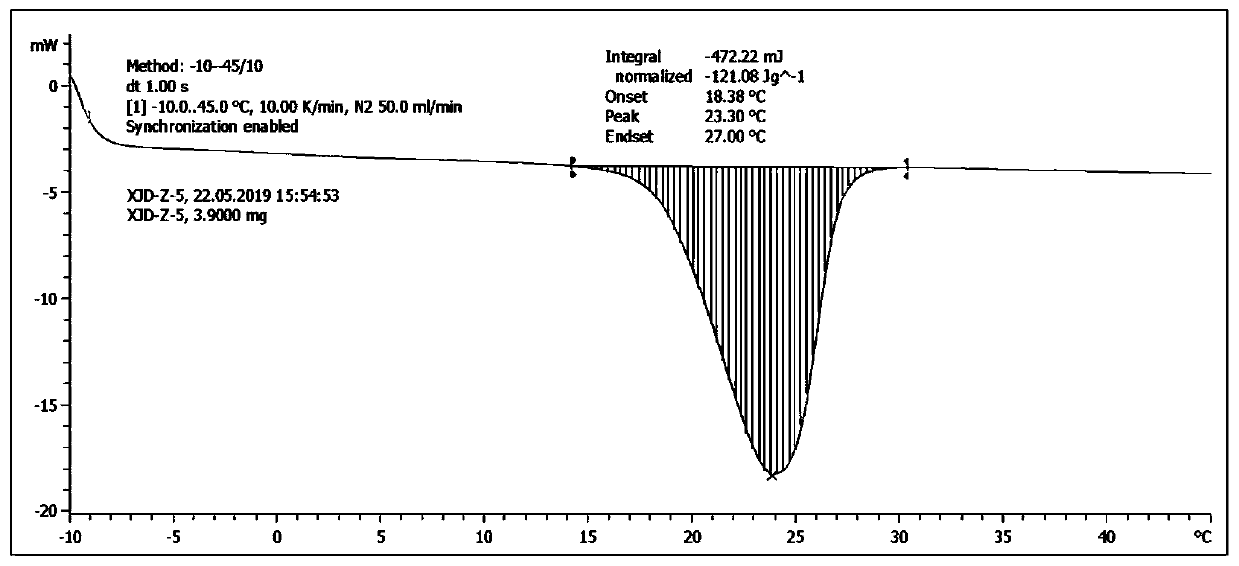

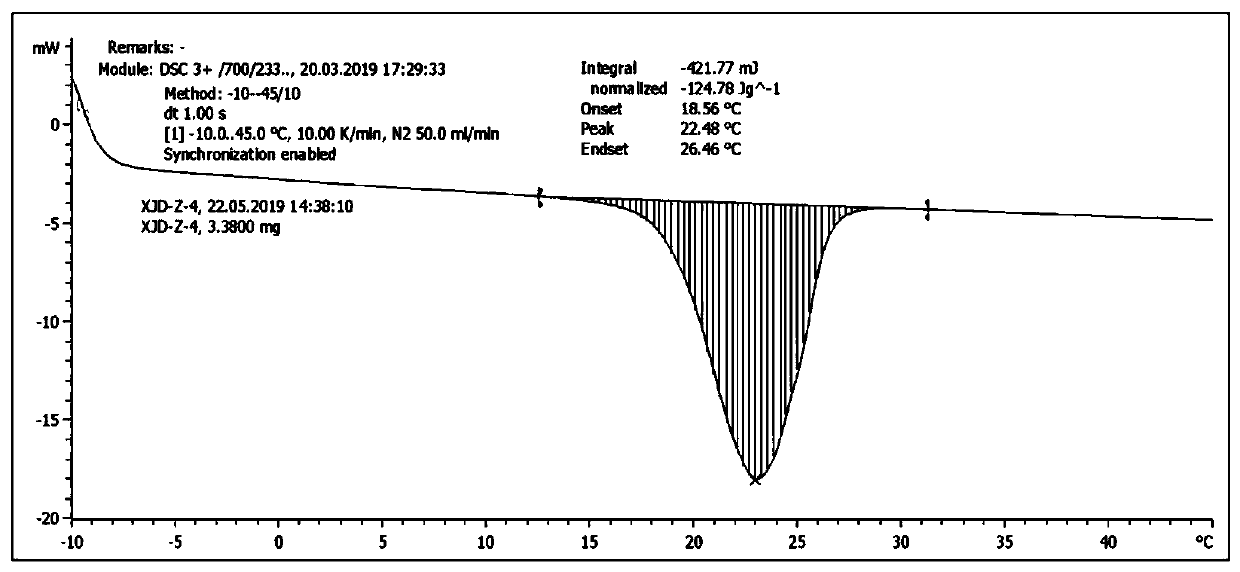

Image

Examples

Embodiment 1

[0026] The steps of this embodiment include:

[0027] (1) Take by weighing capric acid, lauric acid, nano ferric oxide, sodium dodecylbenzenesulfonate and expanded graphite that quality is respectively 60g, 32g, 0.4g, 0.4g, 7.2g;

[0028] (2) Put the weighed capric acid and lauric acid reagents into a beaker, mix well, heat and melt the capric acid and lauric mixed materials with a constant temperature hot water bath at 65°C, and stir evenly with an electric constant temperature stirrer at the same time. for 30 minutes to obtain binary eutectic fatty acids;

[0029] (3) Pour the nanometer iron sesquioxide powder that weighs into the binary eutectic fatty acid that step (2) makes, stir under normal temperature;

[0030] (4) Sodium dodecylbenzenesulfonate (SDBS) is poured into the container of step (3), and stirred evenly at room temperature;

[0031] (5) Put the stirred solution in step (4) together with the container into an ultrasonic oscillator with a water bath temperatur...

Embodiment 2

[0037] The steps of this embodiment include:

[0038] (1) Take by weighing capric acid, lauric acid, nano ferric oxide, sodium dodecylbenzenesulfonate and expanded graphite that are respectively 60.5g, 32.5g, 0.7g, 0.2g, 6.1g;

[0039] (2) Put the weighed capric acid and lauric acid reagents into a beaker, mix well, heat and melt the capric acid and lauric mixed materials with a constant temperature hot water bath at 65°C, and stir evenly with an electric constant temperature stirrer at the same time. for 30 minutes to obtain binary eutectic fatty acids;

[0040] (3) Pour the nanometer iron sesquioxide powder that weighs into the binary eutectic fatty acid that step (2) makes, stir under normal temperature;

[0041] (4) Sodium dodecylbenzenesulfonate (SDBS) is poured into the container of step (3), and stirred evenly at room temperature;

[0042] (5) Put the stirred solution in step (4) together with the container into an ultrasonic oscillator with a water bath temperature o...

Embodiment 3

[0047] (1) Take by weighing capric acid, lauric acid, nano ferric oxide, sodium dodecylbenzenesulfonate and expanded graphite that quality is respectively 61g, 33g, 0.5g, 0.3g, 5.2g;

[0048] (2) Put the weighed capric acid and lauric acid reagents into a beaker, mix well, heat and melt the capric acid and lauric mixed materials with a constant temperature hot water bath at 65°C, and stir evenly with an electric constant temperature stirrer at the same time. for 30 minutes to obtain binary eutectic fatty acids;

[0049] (3) Pour the nanometer iron sesquioxide powder that weighs into the binary eutectic fatty acid that step (2) makes, stir under normal temperature;

[0050] (4) Sodium dodecylbenzenesulfonate (SDBS) is poured into the container of step (3), and stirred evenly at room temperature;

[0051] (5) Put the stirred solution in step (4) together with the container into an ultrasonic oscillator with a water bath temperature of 60°C and a power of 80W for 90 minutes;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition peak temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| phase transition peak temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com