Nanostructured LiNbO3/graphene electrode material and preparation method thereof

A graphene electrode and nanostructure technology, applied in the direction of negative electrodes, structural parts, battery electrodes, etc., to achieve high rate characteristics, improve electrochemical performance, and shorten the effect of ion diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

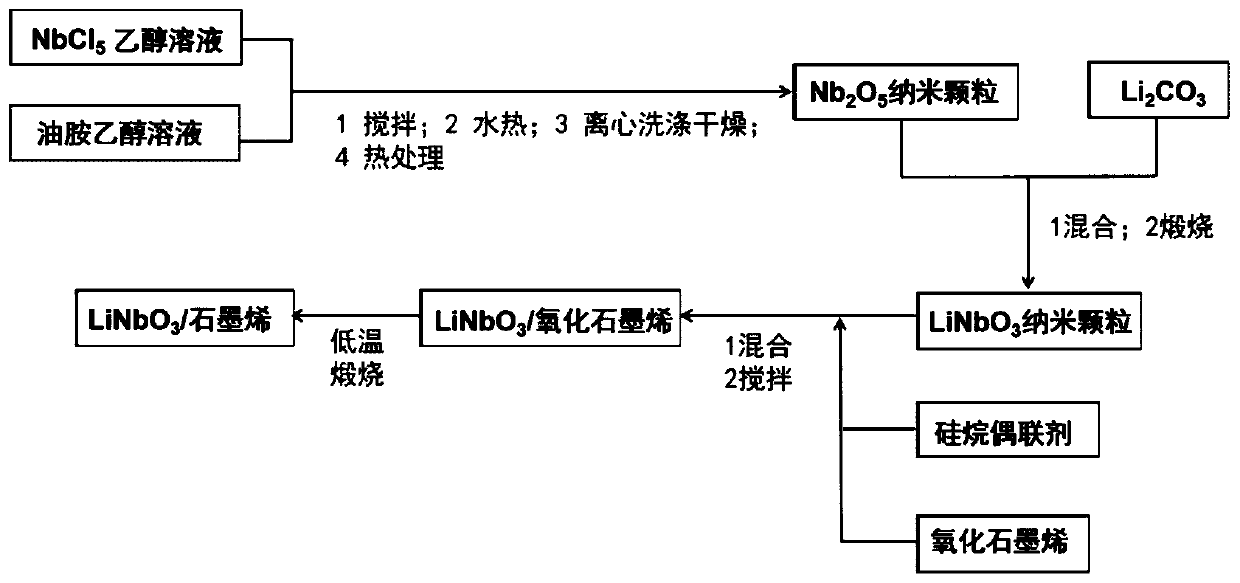

Method used

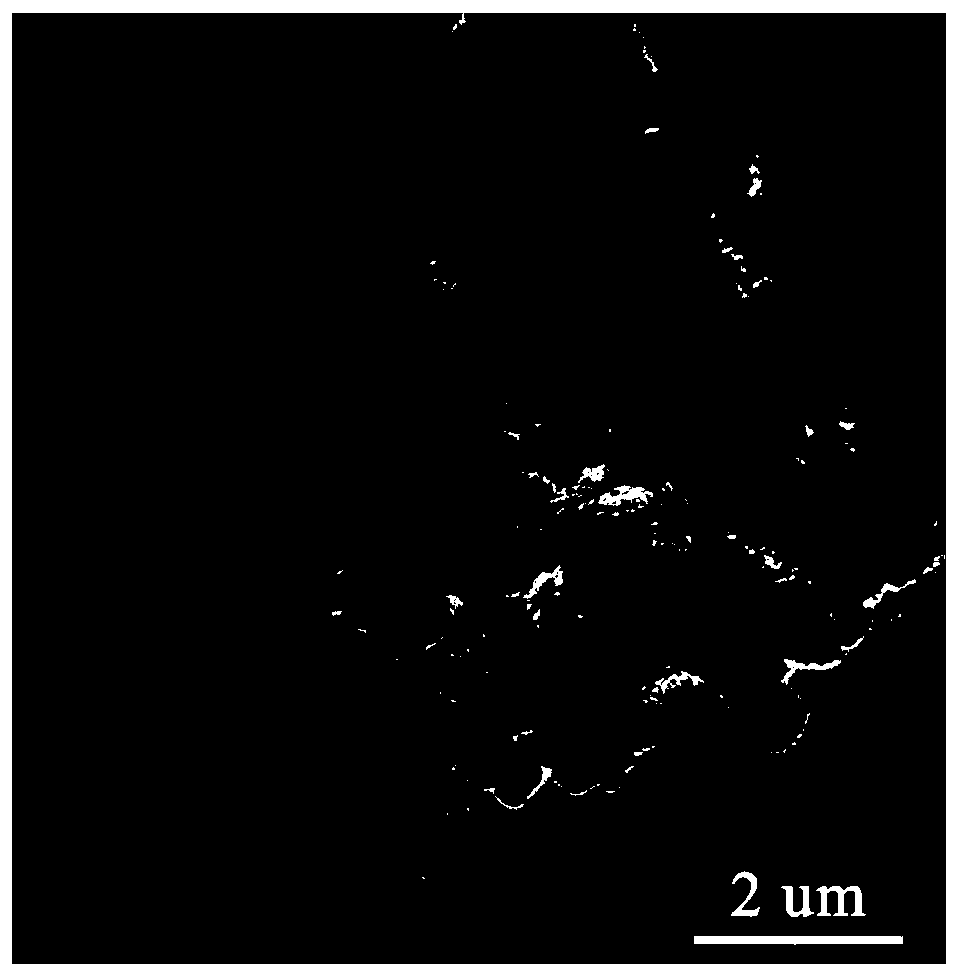

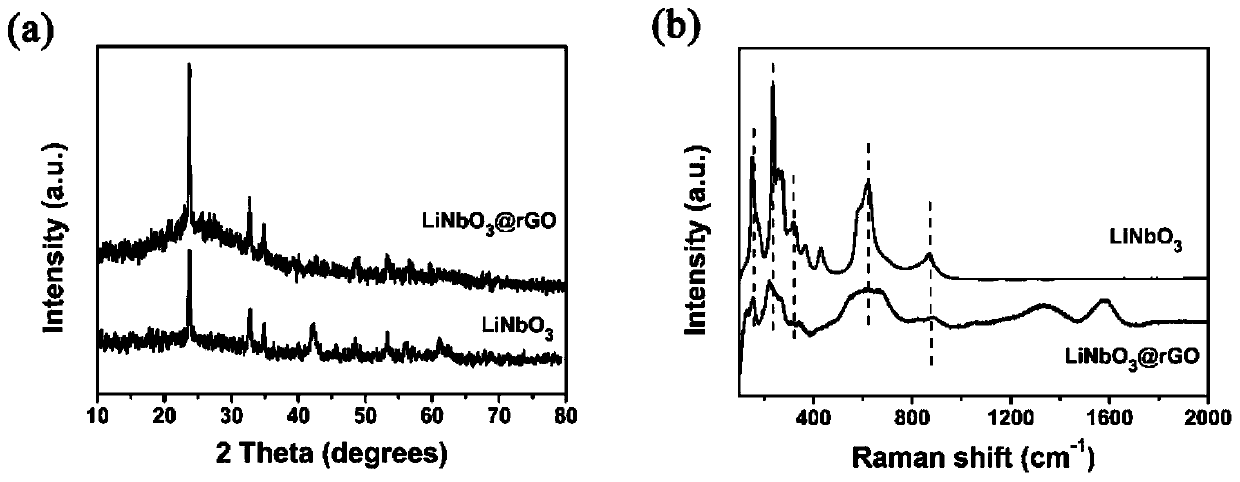

Image

Examples

Embodiment 1

[0032] In the first step, 0.4 mmol of NbCl 5 Dissolve in ethanol, then mix with 5 uL / mL oleylamine ethanol solution, stir thoroughly for 30 min;

[0033] In the second step, the mixed solution of the first step is moved to a hydrothermal kettle, and reacted for 14 h at 180 °C;

[0034] In the third step, the product of the second step is separated, washed, dried, and heat-treated at 600 °C for 2 h under nitrogen to obtain Nb 2 o 5 nanoparticles;

[0035] The fourth step, the third step product Nb 2 o 5 Nanoparticles and Li 2CO 3 Mix and grind, the mass ratio of the two is 1:5, and calcined at 500 °C for 3 h under air to obtain LiNbO 3 nanoparticles;

[0036] The fifth step, the fourth step product LiNbO 3 Disperse 25 mg of nanoparticles into water, add 100 uL of silane coupling agent, and stir thoroughly for 24 h;

[0037] In the sixth step, the above mixed solution was added to a 0.5 mg / mL graphene oxide aqueous dispersion, and after being fully stirred for 2 h, it ...

Embodiment 2

[0041] In the first step, 0.1 mmol of NbCl 5 Dissolve in ethanol, then mix with 1 uL / mL oleylamine ethanol solution, stir thoroughly for 20 min;

[0042] In the second step, the mixed solution of the first step is moved to a hydrothermal kettle, and reacted for 20 h at 150 °C;

[0043] In the third step, the product of the second step is separated, washed, dried, and heat-treated at 600 °C for 1 h under nitrogen to obtain Nb 2 o 5 nanoparticles;

[0044] The fourth step, the third step product Nb 2 o 5 Nanoparticles and Li 2 CO 3 Mix and grind, the mass ratio of the two is 1:4, and calcined at 600 °C for 5 h under air to obtain LiNbO 3 nanoparticles;

[0045] The fifth step, the fourth step product LiNbO 3 Disperse 20 mg of nanoparticles into water, add 50 uL of silane coupling agent, and stir thoroughly for 12 h;

[0046] In the sixth step, the above mixed solution was added to a 0.2 mg / mL graphene oxide aqueous dispersion, stirred thoroughly for 1 h, separated, was...

Embodiment 3

[0050] In the first step, 0.6 mmol of NbCl 5 Dissolve in ethanol, then mix with 10 uL / mL oleylamine ethanol solution, stir thoroughly for 90 min;

[0051] In the second step, the mixed solution of the first step is moved to a hydrothermal kettle, and reacted for 24 h at 120 °C;

[0052] In the third step, the product of the second step is separated, washed, dried, and heat-treated at 600 °C for 3 h under nitrogen to obtain Nb 2 o 5 nanoparticles;

[0053] The fourth step, the third step product Nb 2 o 5 Nanoparticles and Li 2 CO 3 Mix and grind, the mass ratio of the two is 1:2, and calcined at 800 °C for 2 h in the air to obtain LiNbO 3 nanoparticles;

[0054] The fifth step, the fourth step product LiNbO 3 Disperse 100 mg of nanoparticles into water, add 200 uL of silane coupling agent, and stir thoroughly for 28 h;

[0055] In the sixth step, the above mixed solution was added to the 3 mg / mL graphene oxide aqueous dispersion, and after stirring for 5 h, it was sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com