Oxygen-deficient tungsten oxide/polypyrrole core-shell nanowire array electrochromic film and preparation method thereof

A tungsten oxide nanowire, pyrrole core-shell nanotechnology, applied in chemical instruments and methods, color-changing fluorescent materials, coatings, etc., can solve problems such as limiting practical applications, achieve large-scale industrial production, and enhance long-term cycle stability. the effect of increased velocities and rates of ion diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

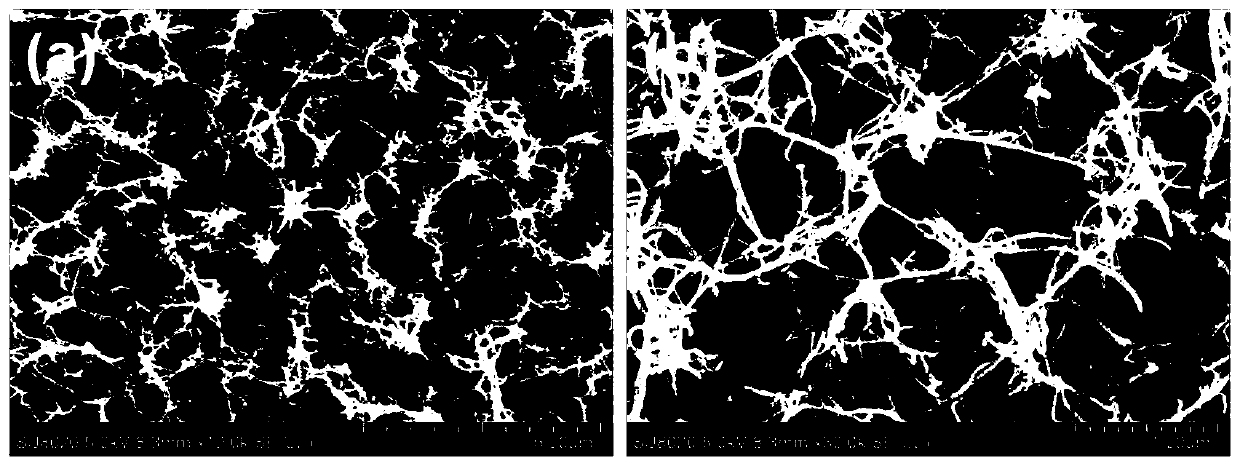

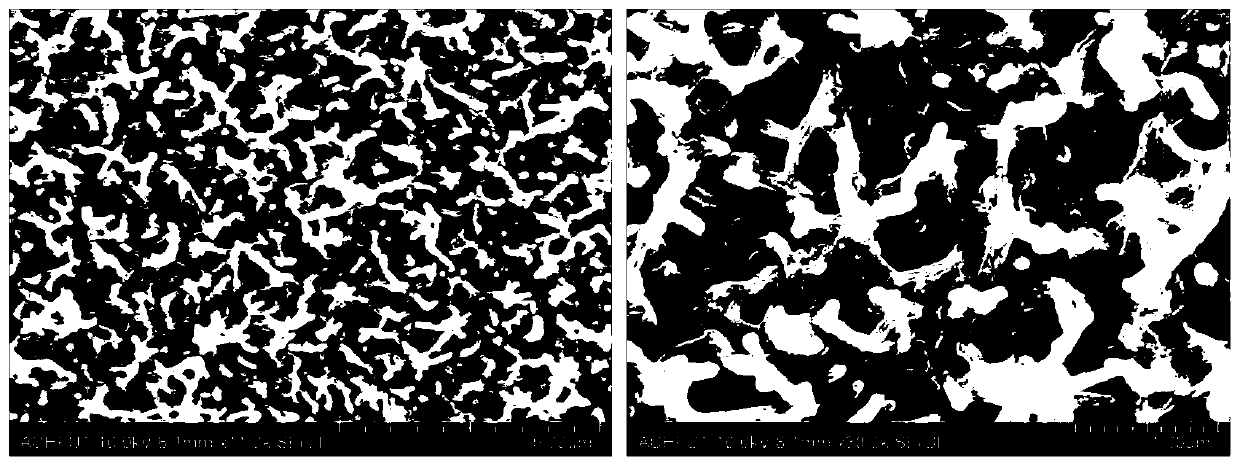

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing an oxygen-deficient tungsten oxide / polypyrrole core-shell nanowire array electrochromic film described in the above technical solution, comprising the following steps:

[0036] The FTO conductive glass is placed in acetone, ethanol and water in sequence and then ultrasonically cleaned and dried to obtain a pretreated FTO conductive glass;

[0037] Mixing citric acid powder, methanol and cyclohexanol and then adding tungsten hexachloride powder to obtain a precursor solution;

[0038] The pretreated FTO conductive glass is soaked in the precursor solution and then subjected to hydrothermal reaction, and then the FTO conductive glass is taken out, washed with alcohol, washed with water and freeze-dried in sequence to obtain an oxygen-deficient tungsten oxide nanometer containing a large number of oxygen vacancies. FTO conductive glass with line array film;

[0039] The FTO conductive glass of the oxygen-deficient...

Embodiment 1

[0055] A preparation method of a tungsten oxide / polypyrrole core-shell nanowire array electrochromic material, the specific steps are as follows:

[0056] (1) The FTO conductive glass was placed in acetone, ethanol, and deionized water in sequence for ultrasonic cleaning for 15 minutes, and then dried under an infrared lamp.

[0057] (2) Preparation of precursor solution: Add 0.6g of citric acid powder to 50mL of methanol and 10mL of cyclohexanol and stir until completely dissolved, then pour 0.16g of tungsten hexachloride powder into the above solution and stir until Yellow and transparent, made into a precursor solution;

[0058] (3) Add the precursor solution prepared in step (2) into the autoclave, soak and fix the FTO conductive glass vertically in the precursor solution, and heat the autoclave to 180°C (heating rate 8°C / min) , kept for 9h; after the hydrothermal reaction, the FTO conductive glass was taken out, the surface was washed several times with alcohol and deion...

Embodiment 2

[0074] Same as Example 1, the only difference is that the freeze-drying temperature in the freeze-drying oven is -80°C, and the scanning electron photo of the electrochromic material obtained is similar to Example 1, at 0.6V, 0V, -0.2V, -0.5V , -0.8V under light gray, reddish-brown, blue-gray, yellow-green and blue-green, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com