Lithium iron phosphate modified composite material and preparation method thereof

A composite material, lithium iron phosphate technology, applied in the direction of electrode manufacturing, active material electrode, electrode heat treatment, etc., can solve the problems of low ion diffusivity, narrow electronic conductivity, etc., to increase specific surface area, improve electronic conductivity, good The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

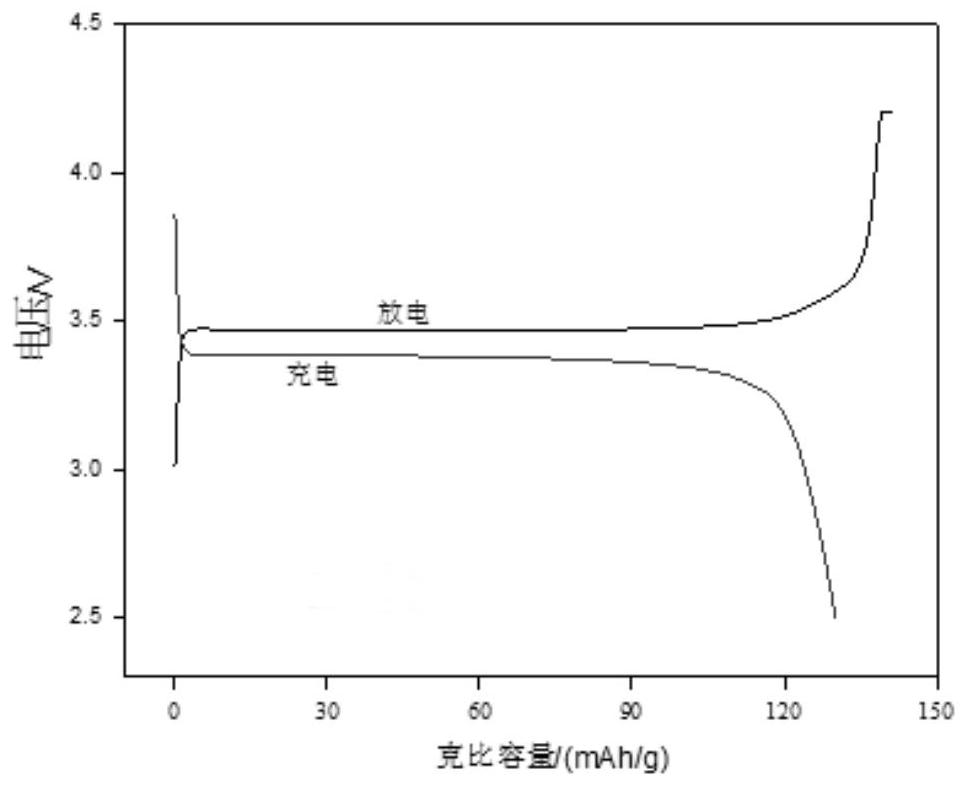

[0029] Embodiment 1: A lithium iron phosphate modified composite material, the lithium iron phosphate modified composite material includes: LiCo x mn y Fe (1-x-y) PO 4 / Metal elemental Ni / graphene, wherein, x=0.1, y=0.1.

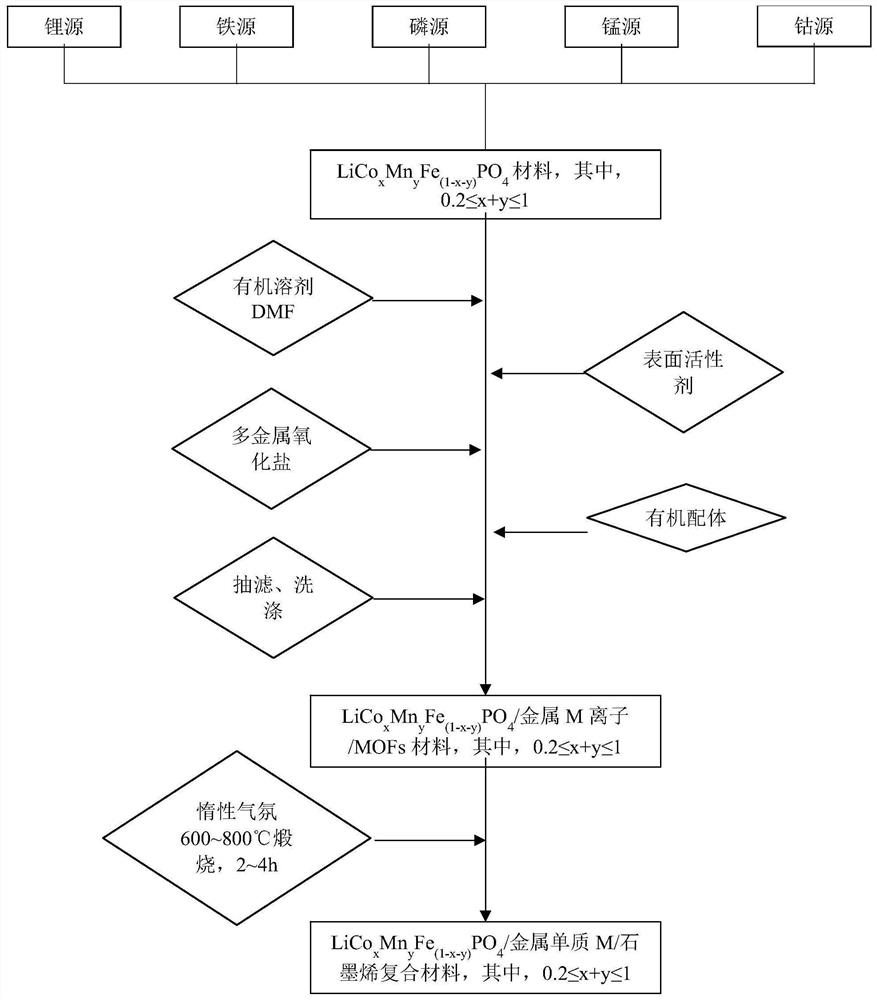

[0030] For the above-mentioned lithium iron phosphate modified composite material, its preparation method comprises the following steps:

[0031] Step 1. Disperse the lithium source, iron source, manganese source, cobalt source, and phosphorus source in absolute ethanol, and ball mill in a ball mill for 5 hours at a speed of 300r / min; pre-sinter at 500°C for 2 hours, and then cool down to At room temperature, the material LiCo 0.1 mn 0.1 Fe 0.8 PO 4 , the particle size is 0.5 μm;

[0032] In this scheme, the lithium source is lithium hydroxide, the iron source is ferric phosphate, the manganese source is manganese acetate, the cobalt source is cobalt acetate, and the phosphorus source is phosphoric acid;

[0033] Step 2, the LiCo prepared in step 10...

Embodiment 2

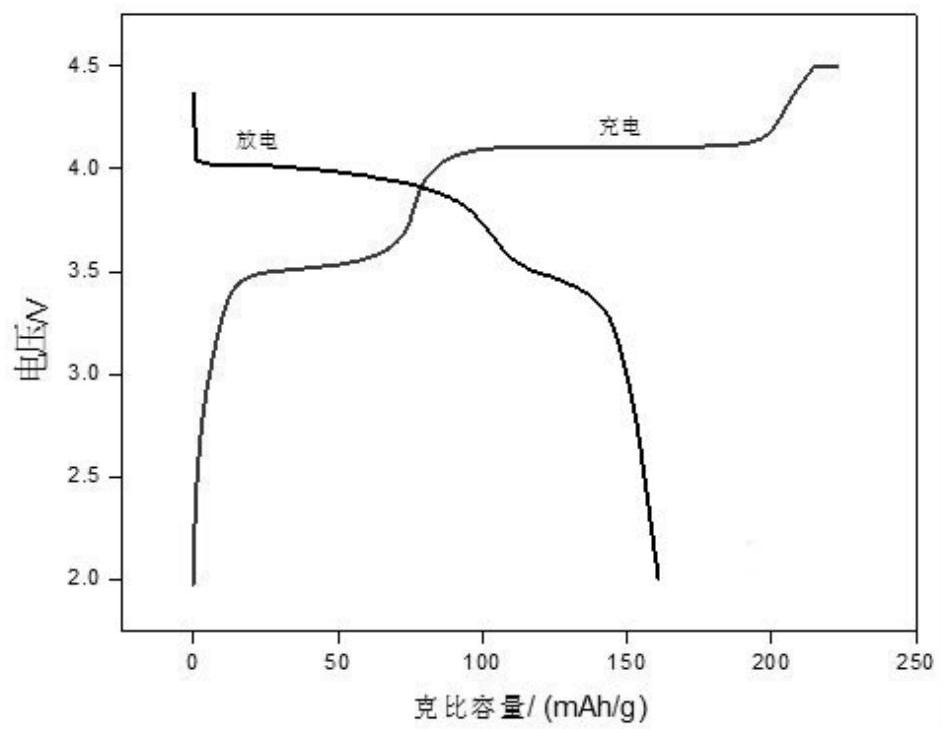

[0037] Embodiment 2: a kind of lithium iron phosphate modified composite material, described lithium iron phosphate modified composite material comprises: LiCo x mn y Fe (1-x-y) PO 4 / Metal simple substance Ag / graphene, wherein, x=0.1, y=0.9.

[0038] For the above-mentioned lithium iron phosphate modified composite material, its preparation method comprises the following steps:

[0039] Step 1. Disperse the lithium source, iron source, manganese source, cobalt source, and phosphorus source in absolute ethanol, and ball mill in a ball mill for 5 hours at a speed of 700r / min; pre-sinter at 700°C for 2 hours, and then cool in the furnace to At room temperature, the material LiCo 0.1 mn 0.9 PO 4 , the particle size is 100nm;

[0040] In this scheme, lithium source selects lithium carbonate, iron source selects ferrous oxalate, manganese source selects manganese nitrate, cobalt source selects cobalt nitrate, phosphorus source selects diammonium phosphate;

[0041] Step 2, ...

Embodiment 3

[0045] Embodiment 3: a kind of lithium iron phosphate modified composite material, described lithium iron phosphate modified composite material comprises: LiCo x mn y Fe (1-x-y) PO 4 / Metal elemental Cu / graphene, wherein, x=0.4, y=0.5.

[0046] For the above-mentioned lithium iron phosphate modified composite material, its preparation method comprises the following steps:

[0047] Step 1. Disperse the lithium source, iron source, manganese source, cobalt source, and phosphorus source in absolute ethanol, and ball mill in a ball mill for 10 hours at a speed of 500r / min; pre-sinter at 600°C for 2.5 hours, and then cool in the furnace to room temperature, the material LiCo 0.4 mn 0.5 Fe 0.1 PO 4 ;

[0048] The lithium source is lithium carbonate, the iron source is ferrous acetate, the manganese source is manganese acetate, the cobalt source is cobalt oxalate, and the phosphorus source is diammonium phosphate;

[0049] Step 2, the LiCo prepared in step 1 0.4 mn 0.5 Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com