Three-dimensional porous black phosphorene/graphene for magnesium ion battery as well as preparation method and applicationgrapheme thereof

A technology for dimensionally porous black phosphorene and magnesium ion batteries, which can be applied to battery electrodes, secondary batteries, circuits, etc., and can solve the problems of cumbersome process and easy influence on the stability of nano black phosphorene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Weigh 500mg of red phosphorus, 80mg of tin powder and 40mg and mix them evenly, put them into a quartz ampoule with a length of 12cm and an inner diameter of 1cm, pass high-purity argon to remove the air, seal it with an oxygen-hydrogen flame, place it in a muffle furnace, and heat it at 1°C / min to 650°C, keep warm for 5h and then cool down to 500°C at 0.3°C / min, keep warm at this temperature for 2h and then cool down to room temperature naturally, break open the quartz ampoule with a tool, take out the black phosphorus crystal and wash it with hot toluene for several times , vacuum-dried to obtain black phosphorus crystals;

[0090] Take 7.75g (0.02mol) of tetrabutylammonium hexafluorophosphate cationic intercalation agent and dissolve it in 40mL N,N-dimethylformamide as the electrolyte, and clamp black phosphorus crystals with a size of 5*5*10mm on the electrode holder As a working electrode, a 10*10*0.5mm platinum plate electrode is used as a counter electrode, and ...

Embodiment 2

[0103] The three-dimensional porous black phosphorene / graphene composite was prepared by the same steps as in Example 1, except that the mass ratio of black phosphorene to graphene in the nano black phosphorene dispersion was 1:0.6.

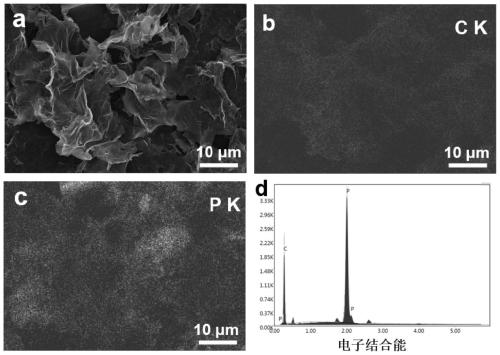

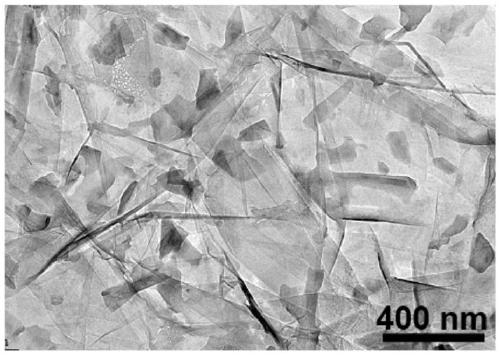

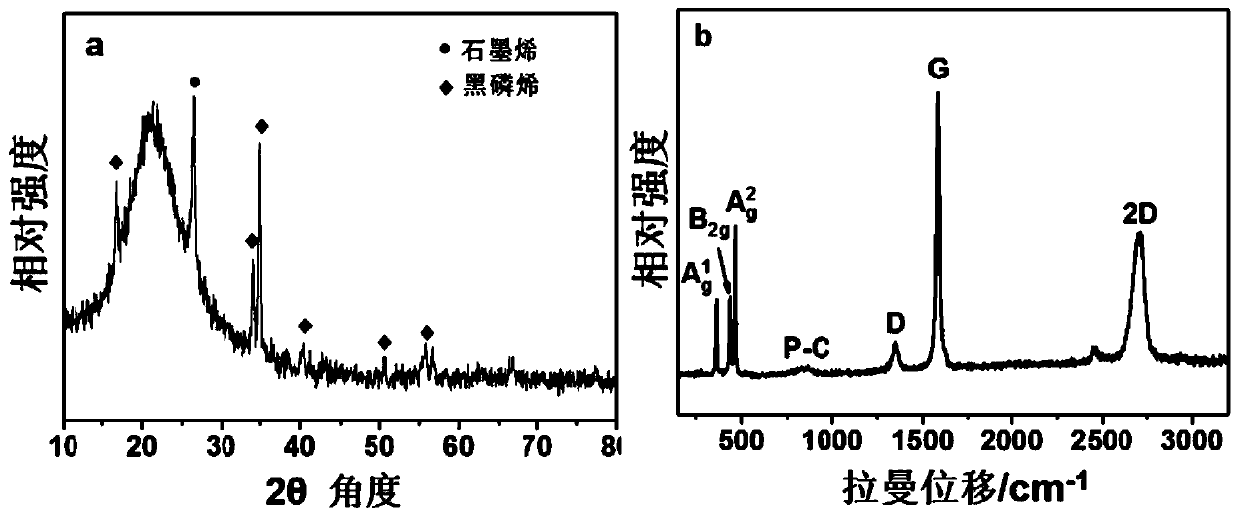

[0104] After testing, the SEM image of the product prepared in this embodiment is as follows Image 6 As shown, the composite material has a three-dimensional porous structure, and black phosphorene is uniformly dispersed on the graphene skeleton.

[0105] The same steps as in Example 1 were used to prepare and assemble a battery, and further performance tests showed that the battery had better electrochemical performance.

Embodiment 3

[0107] The three-dimensional porous black phosphorene / graphene composite was prepared by the same steps as in Example 1, except that the mass ratio of black phosphorene to graphene in the nano black phosphorene dispersion was 1:4.

[0108] After testing, the SEM image of the product prepared in this embodiment is as follows Figure 7 As shown, the composite material has a three-dimensional porous structure, and black phosphorene is uniformly dispersed on the graphene skeleton.

[0109] The same steps as in Example 1 were used to prepare and assemble a battery, and further performance tests showed that the battery had better electrochemical performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet thickness | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com