A kind of preparation method of electrocatalytic oxygen generation film electrode material and its product and application

A thin-film electrode and electrocatalysis technology, which is applied in the direction of electrodes, electrolytic components, and electrolytic processes, can solve the problems of high price and limited practical application of reserves, and achieve the effects of low cost, convenient electron diffusion and transmission, and fast synthesis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

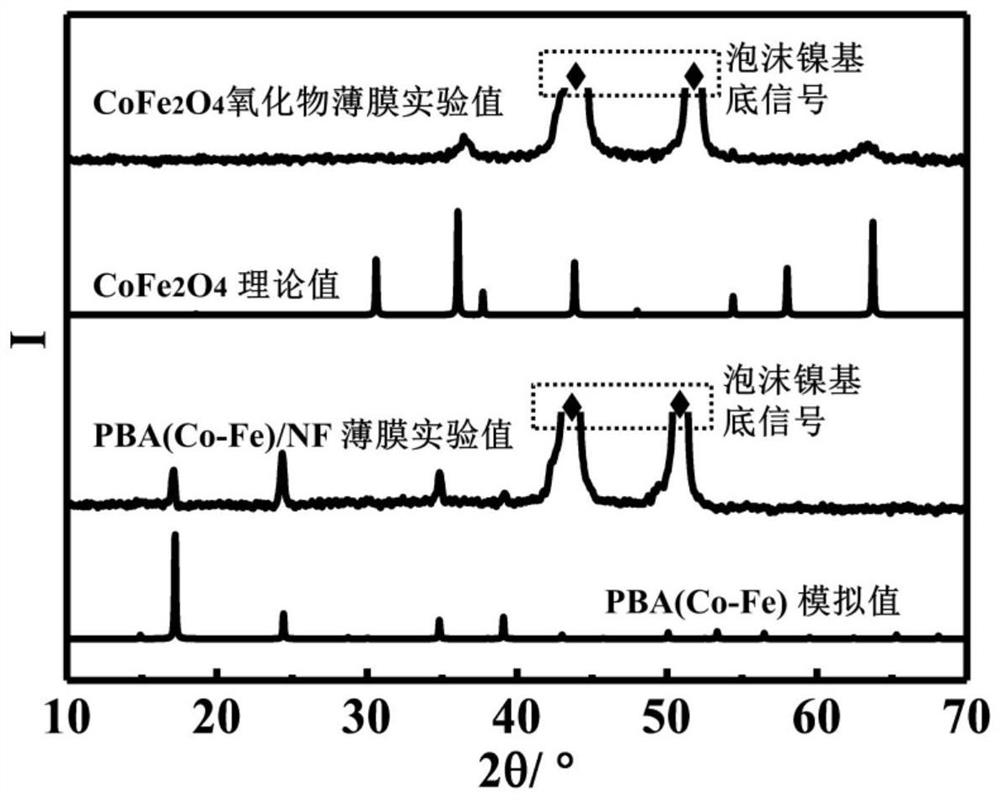

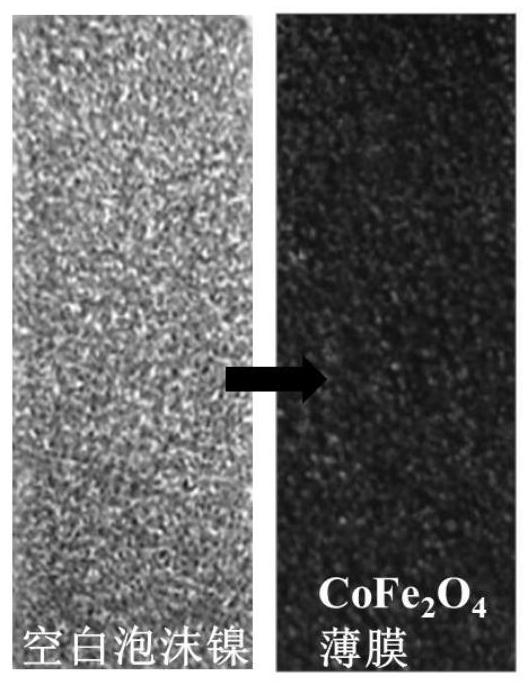

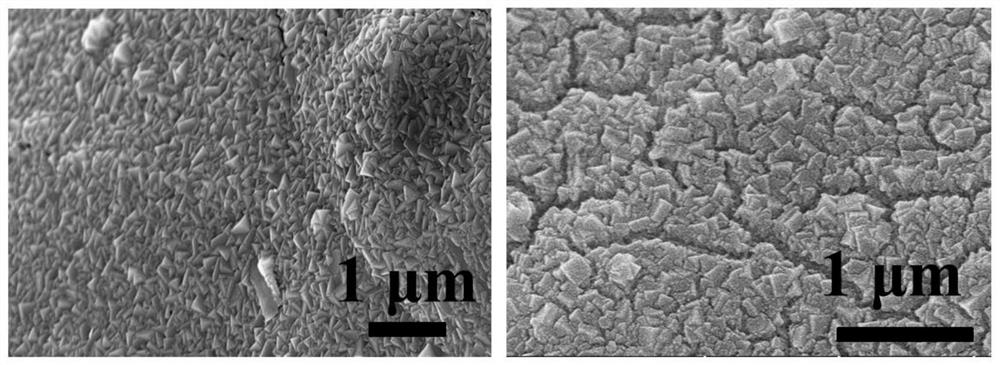

[0077] 1) Preparation of PBA(Co-Fe) / NF Prussian blue analog film

[0078] Weigh cobalt acetate and potassium ferricyanide, dissolve them in distilled water, and prepare 500ml of solutions with concentrations of 3mmol / L and 2mmol / L respectively.

[0079] Take the prepared 3mmol / L cobalt acetate aqueous solution, pour it into a small brown bottle, put the cleaned nickel foam into it, put the small bottle in a 50°C water bath and let it stand for a while, then take out the nickel foam and moisten it with distilled water. Wash, then take the prepared 2mmol / L potassium ferricyanide aqueous solution, pour it into a small brown bottle, put the nickel foam into it, put the small bottle in a 50°C water bath and let it stand for a while, then take out the nickel foam and use distilled water Rinse to complete a full manual soak cycle.

[0080] Wherein, the immersion amount of the cobalt acetate solution is advisable to cover the nickel foam, the immersion time is 20 minutes, the standin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com