Method for preparing adsorption material for selectively separating palladium ions and product

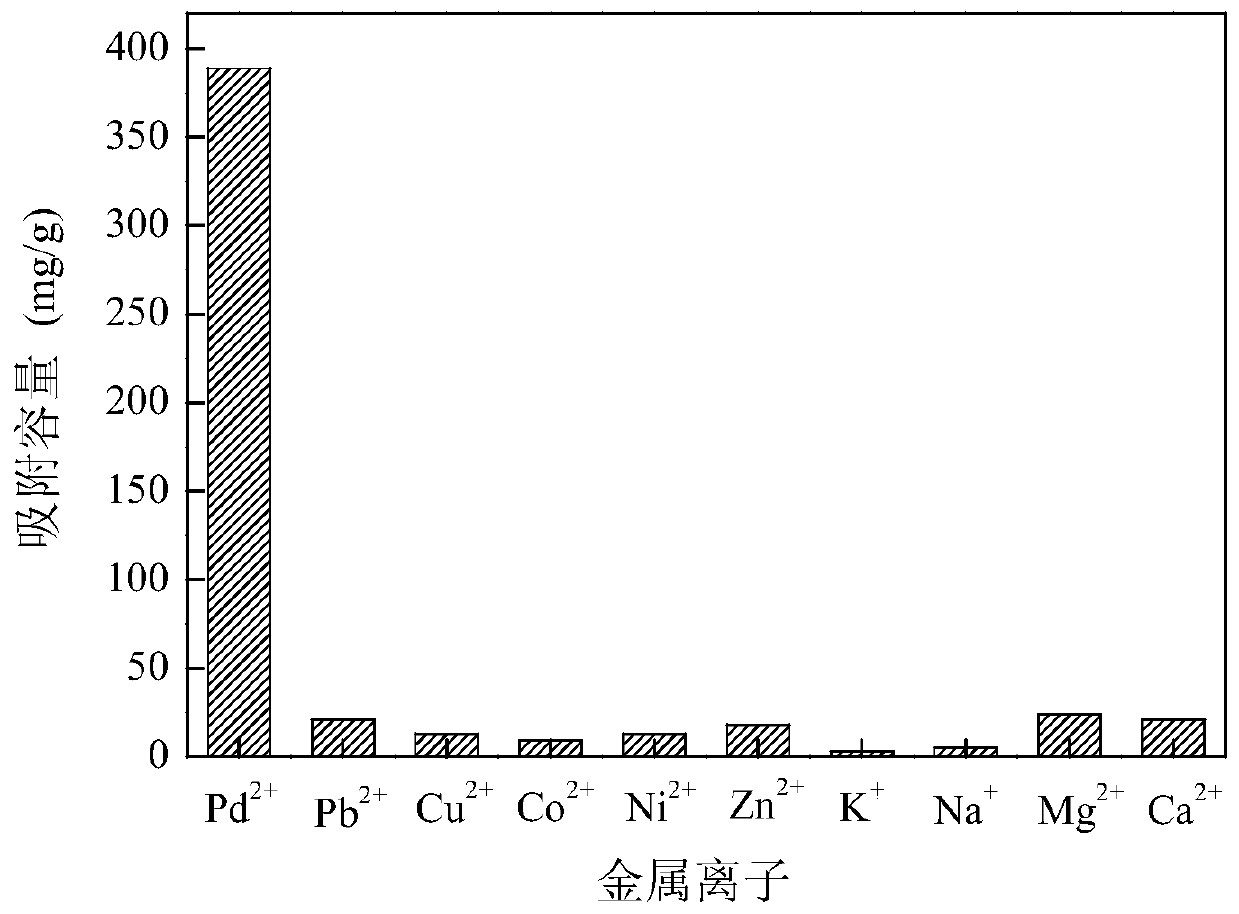

A technology for adsorbing materials and palladium ions, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex process conditions and high cost, and achieve the effect of good selectivity and high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

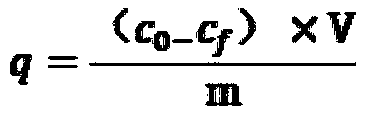

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for selectively separating palladium ion adsorption materials, comprising the steps of:

[0030] 1) Add 60g of chromatographic silica gel and 500mL of 6mol / L hydrochloric acid solution into a 1000mL three-neck flask, heat to 110°C, stir and reflux for 8h, wash it with a large amount of deionized water until neutral after the reaction is completed, and place it at 110°C Dry for 12h to obtain activated silica gel.

[0031] 2) Disperse 25g of activated silica gel in 400mL of toluene solution, add 25mL of γ-aminopropyltriethoxysilane under stirring conditions, and finally add 5mL of aniline, and stir and reflux for 24 hours under the condition of heating to 110°C. After filtration, the solid was dried in a drying oven at 110°C for 12 hours to obtain amino silica gel;

[0032] 3) Disperse 0.85g of graphene oxide in 350mL, N,N dimethylformamide solution, ultrasonically disperse graphene oxide for 30min, then add 25g of amino silica gel and 2.0g of DCC, a...

Embodiment 2

[0038] A preparation method for selectively separating palladium ion adsorption materials, comprising the steps of:

[0039] 1) The preparation of the activated silica gel is the same as described in step 1) of Example 1.

[0040] 2) The preparation of the amino silica gel is the same as described in step 2) of Example 1.

[0041] 3) Disperse 0.85g of graphene oxide in 350mL N,N dimethylformamide solution, ultrasonically disperse graphene oxide for 30min, then add 85g of amino silica gel and 2.0g of DCC, heat in an oil bath at 60°C Stir for 3 days, after the reaction is completed, wash and filter repeatedly with absolute ethanol, and dry in a vacuum oven at 60°C for 12 hours to obtain SiO 2 @GO;

[0042] 4) Add 5gSiO 2 @GO was dispersed in 250mL of toluene solution, and 2.5mL of N-aminoethyl-γ-aminopropyltriethoxysilane and 5mL of γ-mercaptopropyltrimethoxysilane were added to a small beaker to prepare a mixed solution. Slowly add the mixed solution under low temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com