Nitrogen-doped carbon-coated two-phase staggered distribution type nickel-cobalt bimetal selenide electrode material and preparation method thereof

A nitrogen-doped carbon, staggered distribution technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as restricting the energy storage performance of transition metal selenide-based electrode materials, and achieve the effect of improving electrochemical energy storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

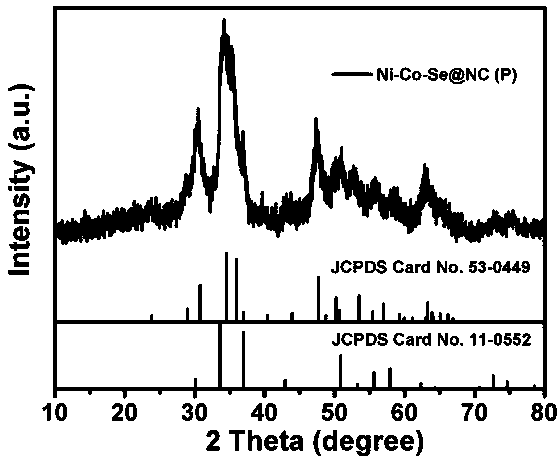

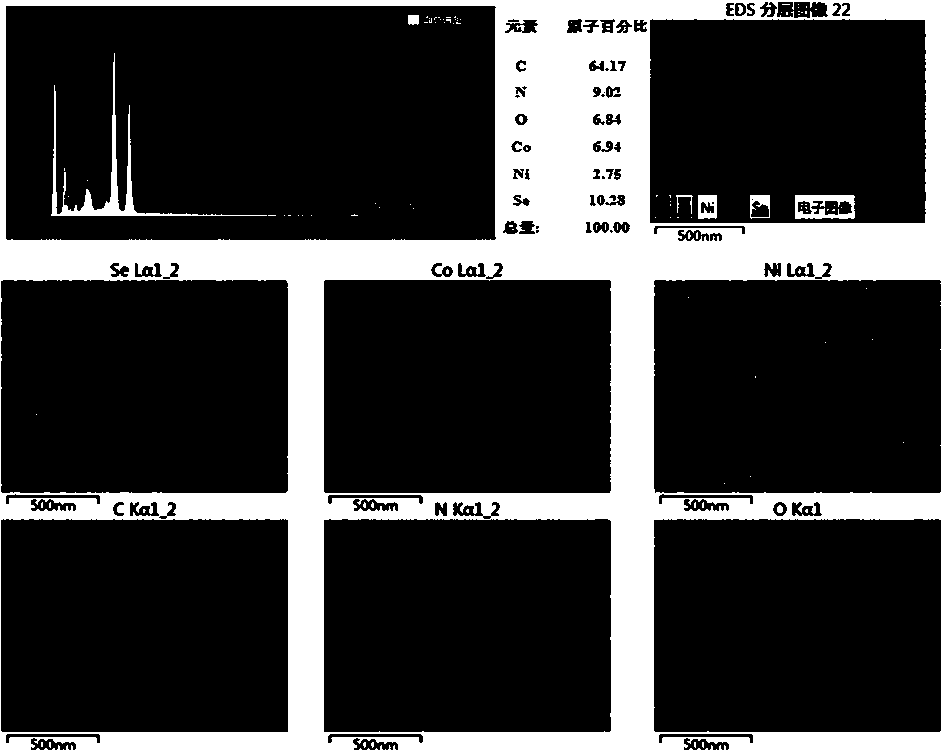

[0025] A method for preparing a nitrogen-doped carbon-coated two-phase staggered distribution type nickel-cobalt double metal selenide electrode material, the specific steps are:

[0026] (1) Weigh 232.4 mg of nickel nitrate, 232.4 mg of cobalt nitrate, 1 g of polyvinylpyrrolidone and 150 mg of trimesic acid into 30 mL of N,N-dimethylformamide, dissolve the above mixture by ultrasonic Transfer to a reaction kettle and place in a blast drying oven at 150 °C for 6 h of solvothermal reaction, then cool it down to room temperature naturally, wash it with absolute ethanol for several times, and finally dry the washed product;

[0027] (2) Weigh 100 mg of the centrifuged-dried product of step (1) and 200 mg of melamine and place them in two porcelain boats, and then place them in an argon-hydrogen protected tube furnace for carbonization and nitrogen doping treatment. The temperature is 450 °C, the treatment time is 2 hours, and finally after it is naturally cooled to room temperatu...

Embodiment 2

[0030] A method for preparing a nitrogen-doped carbon-coated two-phase staggered distribution type nickel-cobalt double metal selenide electrode material, the specific steps are:

[0031] (1) Weigh 155 mg of nickel nitrate, 320 mg of cobalt nitrate, 1 g of polyvinylpyrrolidone and 150 mg of trimesic acid into 30 mL of N,N-dimethylformamide, dissolve the above mixture fully by ultrasonic Transfer it to a reaction kettle and place it in a 150°C blast drying oven for 6 h of solvothermal reaction, then cool it down to room temperature naturally, wash it with absolute ethanol for several times, and finally dry the washed product;

[0032] (2) Weigh 100 mg of the centrifuged-dried product of step (1) and 200 mg of melamine and place them in two porcelain boats, and then place them in an argon-hydrogen protected tube furnace for carbonization and nitrogen doping treatment. The temperature is 450 °C, the treatment time is 2 hours, and finally after it is naturally cooled to room tempe...

Embodiment 3

[0035] A method for preparing a nitrogen-doped carbon-coated single-phase distribution type nickel-cobalt double metal selenide electrode material, the specific steps are:

[0036] (1) Weigh 155 mg of nickel nitrate, 320 mg of cobalt nitrate, 1 g of polyvinylpyrrolidone and 150 mg of trimesic acid into 30 mL of N,N-dimethylformamide, dissolve the above mixture fully by ultrasonic Transfer it to a reaction kettle and place it in a 150°C blast drying oven for 6 h of solvothermal reaction, then cool it down to room temperature naturally, wash it with absolute ethanol for several times, and finally dry the washed product;

[0037] (2) Weigh 100 mg of the centrifuged-dried product of step (1) and 200 mg of melamine and place them in two porcelain boats, and then place them in an argon-hydrogen protected tube furnace for carbonization and nitrogen doping treatment. The temperature is 450 °C, the treatment time is 2 hours, and finally after it is naturally cooled to room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com