Preparation method of polysubstituted bromofluoro-substituted phenylbenzimidazole compound

A reaction kettle and body technology, applied in the field of pharmaceutical intermediates, can solve the problems of not easy condensation, device collapse, difficult reaction mixture, etc., and achieve the effects of avoiding reaction removal, stable stirring and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

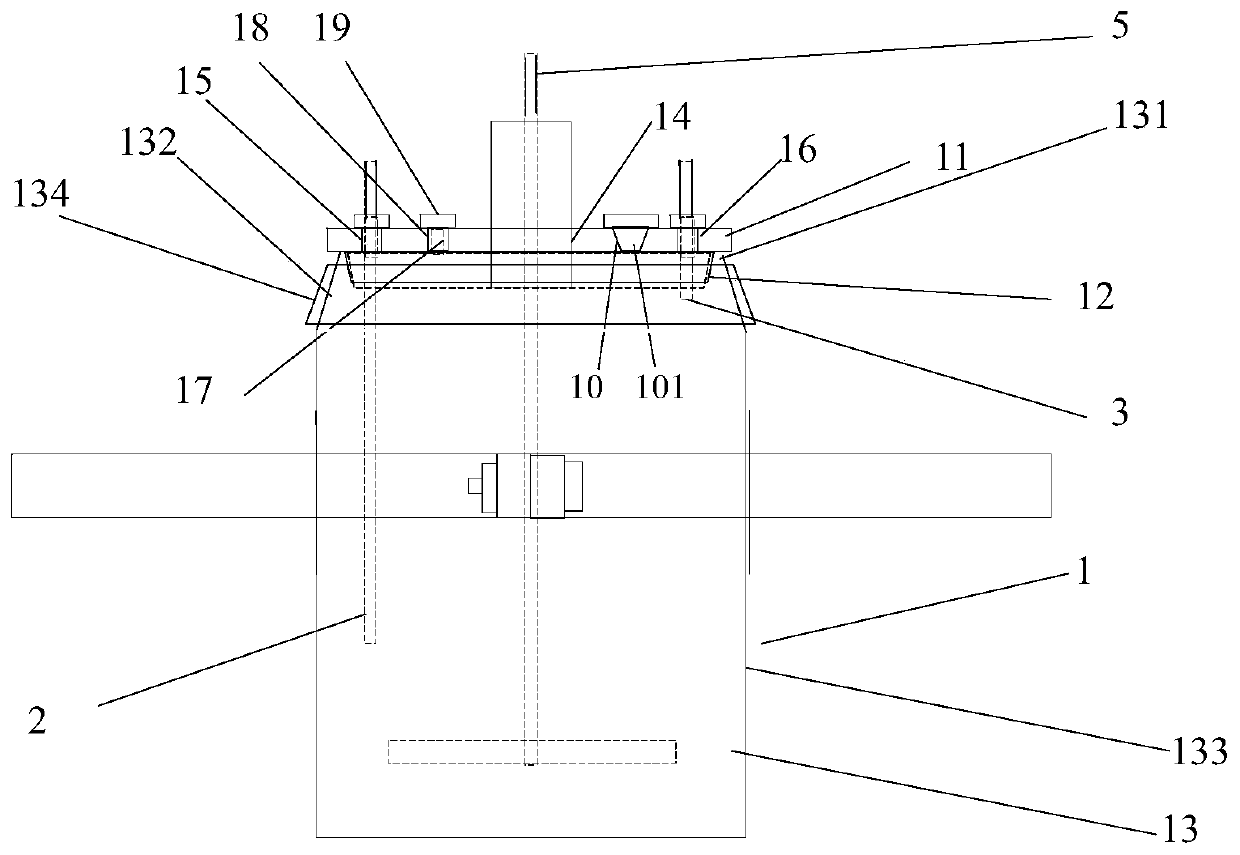

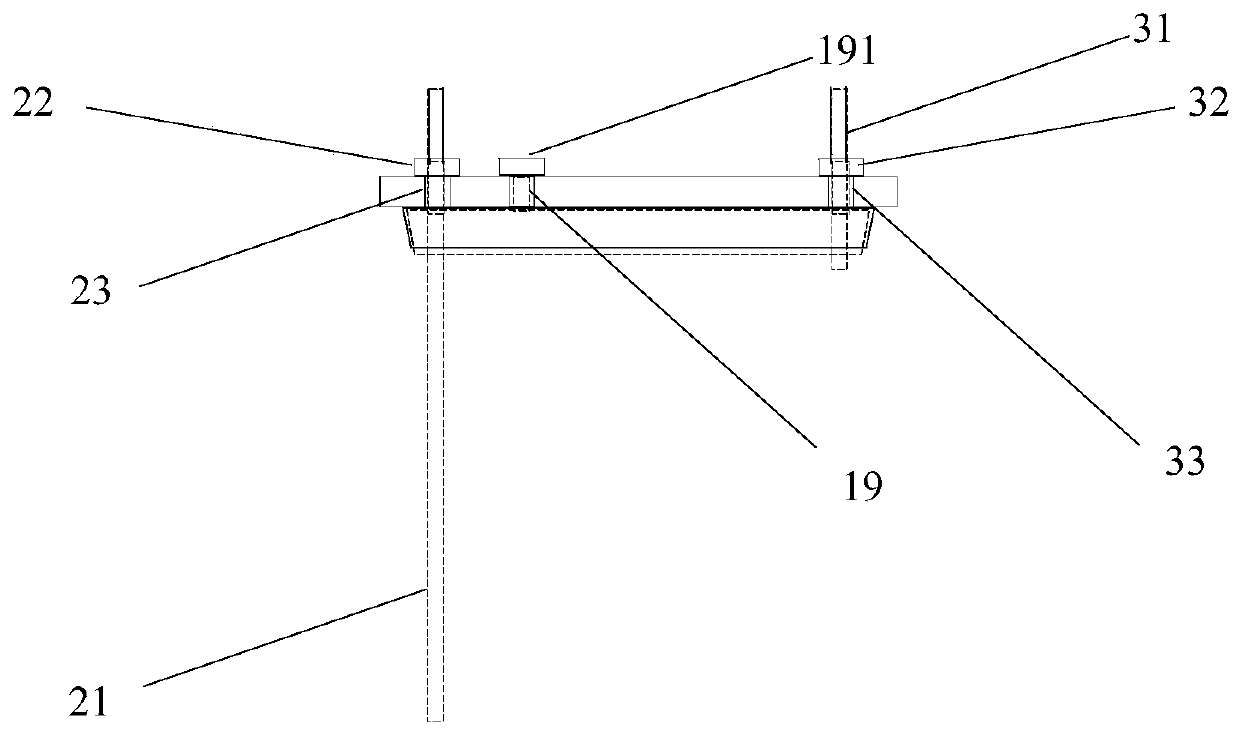

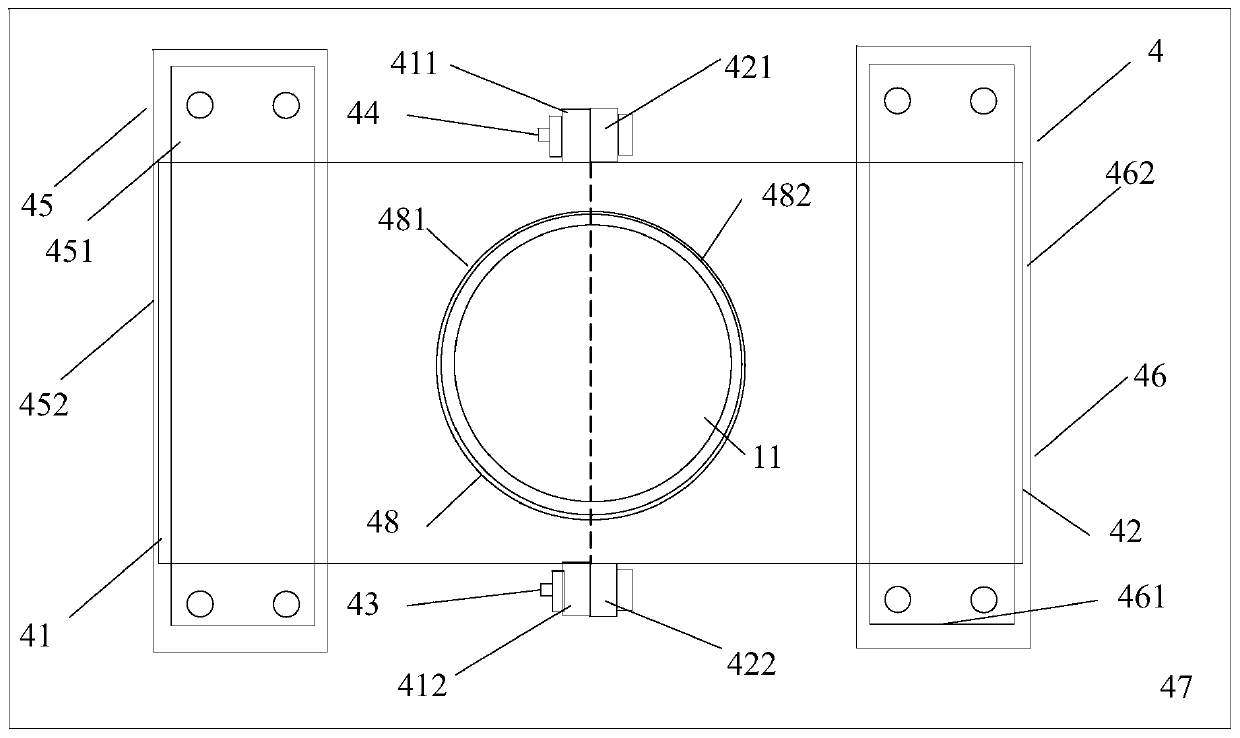

[0037] A reaction kettle, which has a body 1 made of glass, the body is equipped with a kettle cover 11, a lower flange 12, and a cylinder body 13. It is characterized in that: the reaction kettle also includes an air inlet combination 2, an air outlet combination 3, and a fixing device 4. Stirring section 5. The reaction kettle has improved the overall problems of the current four-neck bottle system as a whole: it is not stable enough, the bottom contact area is small, the heating and cooling are slow, the stirring speed cannot be increased, the nitrogen protection effect is not good, and the feeding must be completely opened, and it is very difficult to remove the reaction mixture. Troublesome and difficult to solve the problem.

[0038]The center of kettle lid 11 has middle hole 14, and middle hole 14 is the circular through hole that the center is positioned at kettle lid 11 centers, and its inner side surface is frosted shape, is used for bonding with the peripheral surfa...

Embodiment 2

[0049] 1) Get a reaction kettle as claimed in claim 2, clean and dry, fix the body 1 on the fixture 4, open the kettle cover 11, add 500ml of water first, then add 21g of hydroxylamine hydrochloride, 113g of sodium sulfate, 20g of 2-bromo-5-fluoroaniline, then add 2N HCl of 25ml, close the lid 11, stir at a speed of 680 rev / min for 10min, slow down to 140 rev / min, and slowly Add 18.1g of chloral hydrate at a speed, put the cooling element 134 on the neck 132 and fix it, pass into normal temperature cooling water from the water inlet pipe at a speed of 80ml / min and draw it out from the water outlet pipe, and heat the system to React at 55°C for 16 hours, remove the cooling element 134 and the water bath, and keep stirring to cool the system to room temperature. The solids to be precipitated will not increase, filter with suction, wash with water, and dry in a vacuum oven to obtain the product (E)-N of step 1. -(2-bromo-5-fluorophenyl)-2-(hydroxylamine)acetamide 17.5 g.

[0050...

Embodiment 3

[0055] 1) Get a reaction kettle as claimed in claim 2, clean and dry, fix the body 1 on the fixture 4, open the kettle cover 11, add 500ml of water first, then add 22g of hydroxylamine hydrochloride, 114g of sodium sulfate, The 2-bromo-5-fluoroaniline of 21g, add the HCl of 2N of 27ml again, close kettle lid 11, stir 10min with the rotating speed of 640 revs / min, slow down to 160 revs / min, slowly through feeding hole 18 Add 18.2g of chloral hydrate at a speed, put the cooling element 134 on the neck 132 and fix it, pass into normal temperature cooling water from the water inlet pipe at a speed of 100ml / min and draw it out from the water outlet pipe, and heat the system to React at 58°C for 17 hours, remove the cooling element 134 and the water bath, and keep stirring to cool the system to room temperature. The solids to be precipitated will basically no longer increase, filter with suction, wash with water, and dry in a vacuum oven to obtain the product (E)-N of step 1. -(2-br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com