Manufacturing process of sun-proof gold stamping film

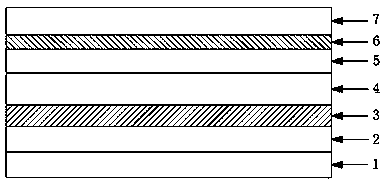

A production process and technology of bronzing film, applied in the field of bronzing film, can solve problems such as poor sun protection effect, accelerated aging of electroplating layer, decolorization of information layer, etc., and achieve the effect of improving heat insulation effect, reducing oxidation speed and improving shielding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the waterproof and heat-insulating layer 3 is composed of the following raw materials in mass percentage: 15% of modified potassium hexatitanate whisker, 25% of POAA-carbonized rice tube-ATO hybrid material, 35% of water-based epoxy resin, hydrophobic Polymer 25%; UV absorbing layer 5 is composed of the following raw materials in mass percentage: UV absorber 35%, polyethylene 30%, polyvinyl chloride 20%, polytrimethylene terephthalate 5%, nano-alumina solution 5 %, nano-indium tin oxide paste 5%.

[0035] In this embodiment, preferably, the POAA-carbonized rice tube-ATO hybrid material is composed of the following mass percentage raw materials: 50% cage-type silsesquioxane POSS, 5% activated carbon nanotubes, 5% nano antimony-doped carbon dioxide Tin ATO.

[0036] In this embodiment, preferably, the hydrophobic polymer is composed of the following raw materials in mass percentage: polyolefin 45%, polycarbonate 20%, polyamide 45%.

Embodiment 2

[0038] In this embodiment, the structure is the same as that of Embodiment 1, wherein the waterproof and heat-insulating layer 3 is composed of the following raw materials in mass percentage: 30% of modified potassium hexatitanate whiskers, 10% of POAA-carbonized rice tube-ATO hybrid material, 35% water-based epoxy resin, 25% hydrophobic polymer; the ultraviolet absorbing layer 5 is composed of the following raw materials in mass percentage: 20% ultraviolet absorber, 25% polyethylene, 10% polyvinyl chloride, polytrimethylene terephthalate 20%, nano-alumina solution 15%, nano-indium tin oxide paste 10%.

[0039] In this embodiment, preferably, the POAA-carbonized rice tube-ATO hybrid material is composed of the following mass percentage raw materials: 30% cage-type silsesquioxane POSS, 5% activated carbon nanotubes, 5% nano antimony-doped carbon dioxide Tin ATO.

[0040] In this embodiment, preferably, the hydrophobic polymer is composed of the following raw materials in mass ...

Embodiment 3

[0042] In this embodiment, the structure is the same as the above two embodiments, wherein the waterproof and heat-insulating layer 3 is composed of the following raw materials in mass percentage: 25% of modified potassium hexatitanate whiskers, 20% of POAA-carbonized rice tube-ATO hybrid material %, water-based epoxy resin 25%, hydrophobic polymer 30%; the ultraviolet absorbing layer 5 is composed of the following raw materials in mass percentage: ultraviolet absorber 30%, polyethylene 25%, polyvinyl chloride 20%, poly(propylene terephthalate) 10% diester, 10% nano-alumina solution, 5% nano-indium tin oxide paste.

[0043] In this embodiment, preferably, the POAA-carbonized rice tube-ATO hybrid material is composed of the following mass percentage raw materials: 10% cage-type silsesquioxane POSS, 5% activated carbon nanotubes, 5% nano antimony-doped dioxide Tin ATO.

[0044] In this embodiment, preferably, the hydrophobic polymer is composed of the following raw materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com