Refined plant polysaccharide, preparing method and application to preparing cosmetics

A technology of plant polysaccharides and total polysaccharides, which is applied in the field of preparation of cosmetics and refined plant polysaccharides, can solve the problems of resource waste and low utilization, and achieve the effect of promoting skin repair, proliferation and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

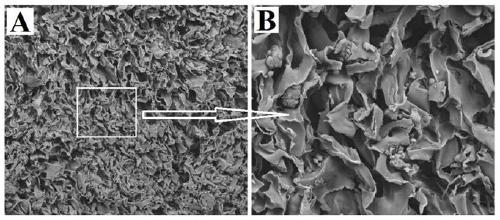

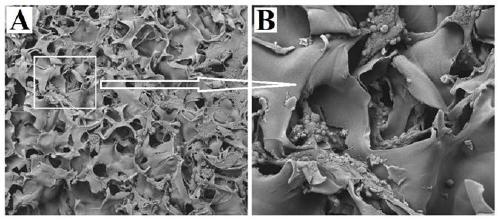

Image

Examples

Embodiment Construction

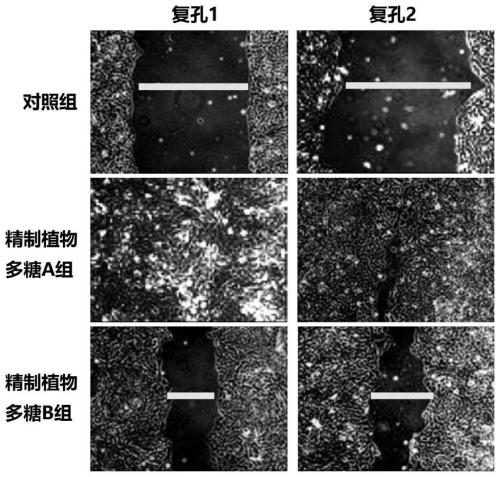

[0025] 1. Experimental method

[0026] 1. Preparation of refined plant polysaccharides A and B

[0027] (1) Preparation of total polysaccharide: Grind the dried whole plant of Butterbur, add absolute ethanol and heat reflux for 3 hours to degrease according to the material-to-liquid ratio of 1:5 (kg:L), repeat the degreasing once, filter, and filter the residue according to the material liquid Add distilled water at a ratio of 1:10 (kg:L), heat and extract at 85°C for 12 hours, filter, collect the filtrate, concentrate the filtrate under reduced pressure to an extract, add distilled water according to the ratio of material to liquid 1:5 (kg:L), and stir to fully Dissolve, filter with suction, add 4 times the volume of absolute ethanol to the filtrate, stir evenly, precipitate with alcohol for 12 hours, centrifuge, discard the supernatant, wash with acetone and absolute ethanol in turn, dissolve with an appropriate amount of distilled water, and freeze-dry to obtain total butte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com