A kind of ultrahigh molecular weight polyethylene catalyst and preparation method thereof

An ultra-high molecular weight and catalyst technology, applied in the field of olefin polymerization catalysts, can solve the problem of sacrificing the industrial production efficiency and reprocessability of polyethylene resin, low molecular weight of ultra-high molecular weight polyethylene, poor specific surface area, pore size, and pore volume, etc. problems, to achieve the effect of improving material transfer speed, good shape and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

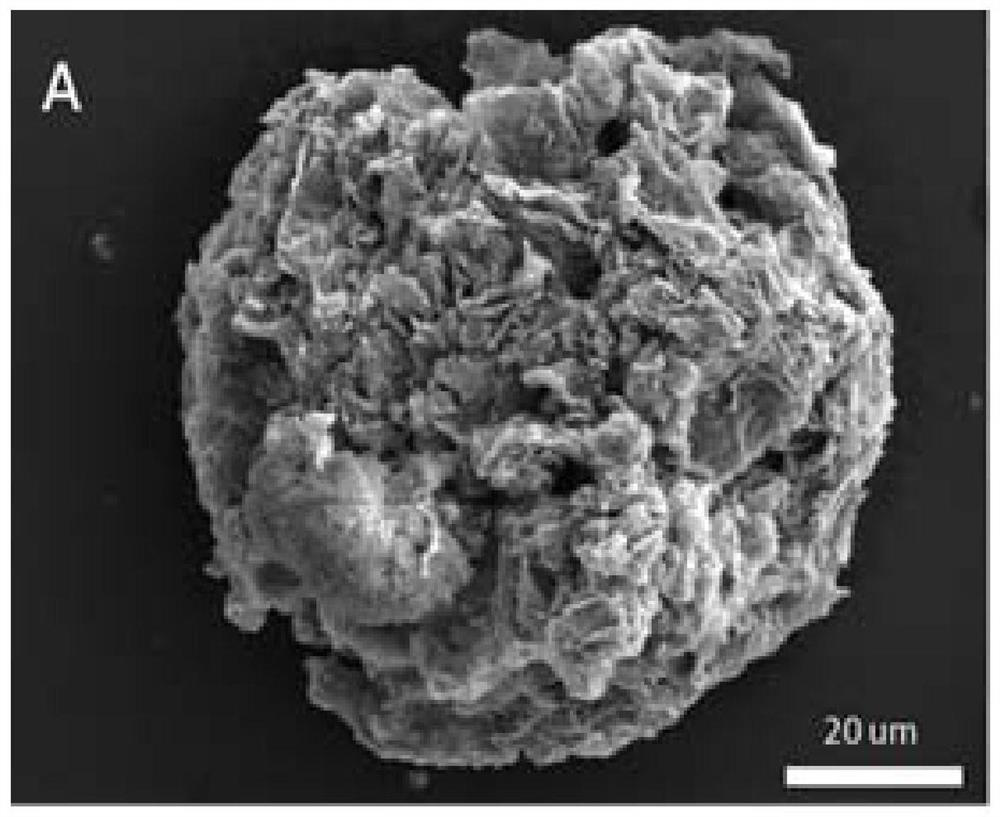

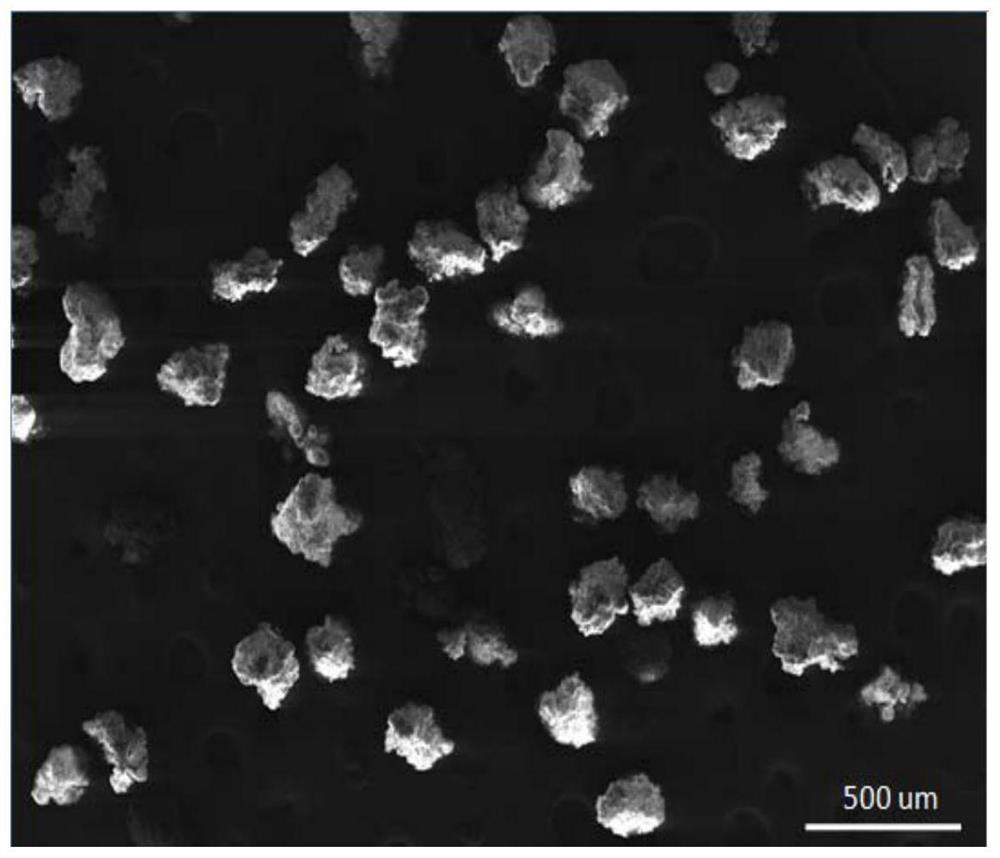

[0026] 1) Preparation of graphene oxide carrier

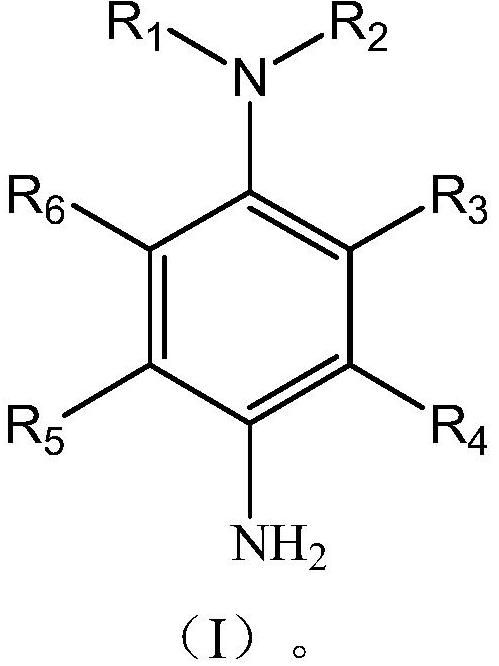

[0027] 10 grams of graphene oxide was prepared into a 10 mg / mL aqueous solution with deionized water, and after ultrasonic treatment for 45 minutes, 4 grams of (Z)-mono-9-octadecenoic acid sorbitan ester and 2 grams of hexadecylsulfonic acid were added sodium. After being stirred by a homogenizer at 3500 R / min for 30 minutes, 5 g of N,N-diethyl-p-phenylenediamine was added, and heated to 80° C. in the reactor for 2 hours to react. After cooling to room temperature, wash with anhydrous hexane, vacuum dry and set aside, the average particle size of the graphene carrier is 25 μm, and the specific surface area is 96m 2 / g.

[0028] 2) Catalyst preparation

[0029] Take 0.5 g of the above-mentioned graphene-like spherical carrier material in a three-necked flask fully replaced with nitrogen, and add 50 mL of n-heptane and 50 mL of titanium tetrachloride successively at -20 ° C. After constant temperature reaction for 2 hours, add...

Embodiment 2

[0033] 10 grams of graphene oxide was prepared into a 12 mg / mL aqueous solution with deionized water, and after ultrasonic treatment for 30 minutes, 5 grams of (Z)-mono-9-octadecenoic acid sorbitan ester and 1.5 grams of hexadecyl sulfonate were added Sodium acid. After being stirred by a homogenizer at 4000 R / min for 30 minutes, 3 g of N,N-dibutyl-p-phenylenediamine was added, and heated to 100° C. in the reactor for 3 hours to react. After cooling to room temperature, wash with anhydrous hexane, dry in vacuum and set aside. The average particle size of the graphene carrier is 18 μm, and the specific surface area is 87 m 2 / g.

[0034] Catalyst preparation and polymerization reaction are the same as embodiment 1.

Embodiment 3

[0036]10 grams of graphene oxide was prepared into an 8 mg / mL aqueous solution with deionized water, and after ultrasonic treatment for 50 minutes, 8 grams of (Z)-mono-9-octadecenoic acid sorbitan ester and 3 grams of hexadecylsulfonic acid were added sodium. After being stirred by a homogenizer at 5000 R / min for 30 minutes, 6 g of N,N-dipropyl-p-phenylenediamine was added, and heated to 120° C. in the reactor for 2.5 hours to react. After cooling to room temperature, wash with anhydrous hexane, dry in vacuum and set aside. The average particle size of the graphene carrier is 15 μm, and the specific surface area is 78 m 2 / g.

[0037] Catalyst preparation and polymerization reaction are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com