High-strength high-toughness freeze-resistant heat-resistant polyacrylamide organic hydrogel and preparation method thereof

A polyacrylamide and hydrogel technology, which is applied in the field of functional polymer materials, achieves wide application prospects, excellent mechanical properties, and broadens the temperature range of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of a high-strength, frost-resistant and heat-resistant polyacrylamide organic hydrogel, comprising the following steps:

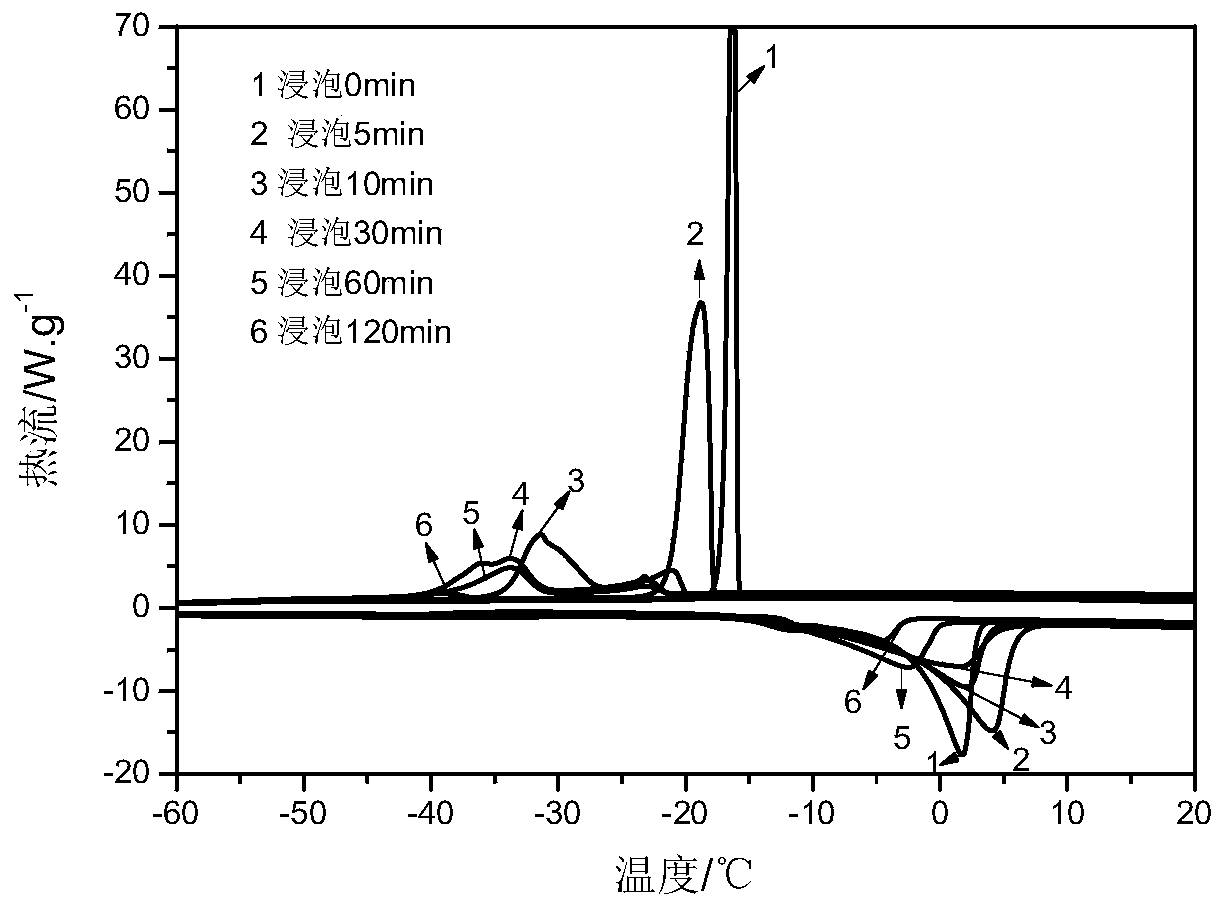

[0042] The polyacrylamide hydrogel is soaked in polypropylene glycol to obtain a high-strength antifreeze and heat-resistant polyacrylamide organic hydrogel.

[0043] Wherein, the polyacrylamide hydrogel is prepared according to the following steps:

[0044] Disperse the acrylamide monomer and crosslinking agent in water first, then add the initiator, then drop the catalyst, and stir to obtain a mixed solution;

[0045] Ultrasonic defoaming is performed on the mixed solution; the reaction temperature of the mixed solution after ultrasonic defoaming is controlled at 25° C. and kept for 4-24 hours to obtain a polyacrylamide hydrogel.

[0046] The preparation method is based on the same inventive concept as the aforementioned high-strength, toughness, freeze-resistant, and heat-resistant polyacry...

Embodiment 1

[0051] A method for preparing a high-strength, frost-resistant and heat-resistant polyacrylamide organic hydrogel, specifically comprising the following steps:

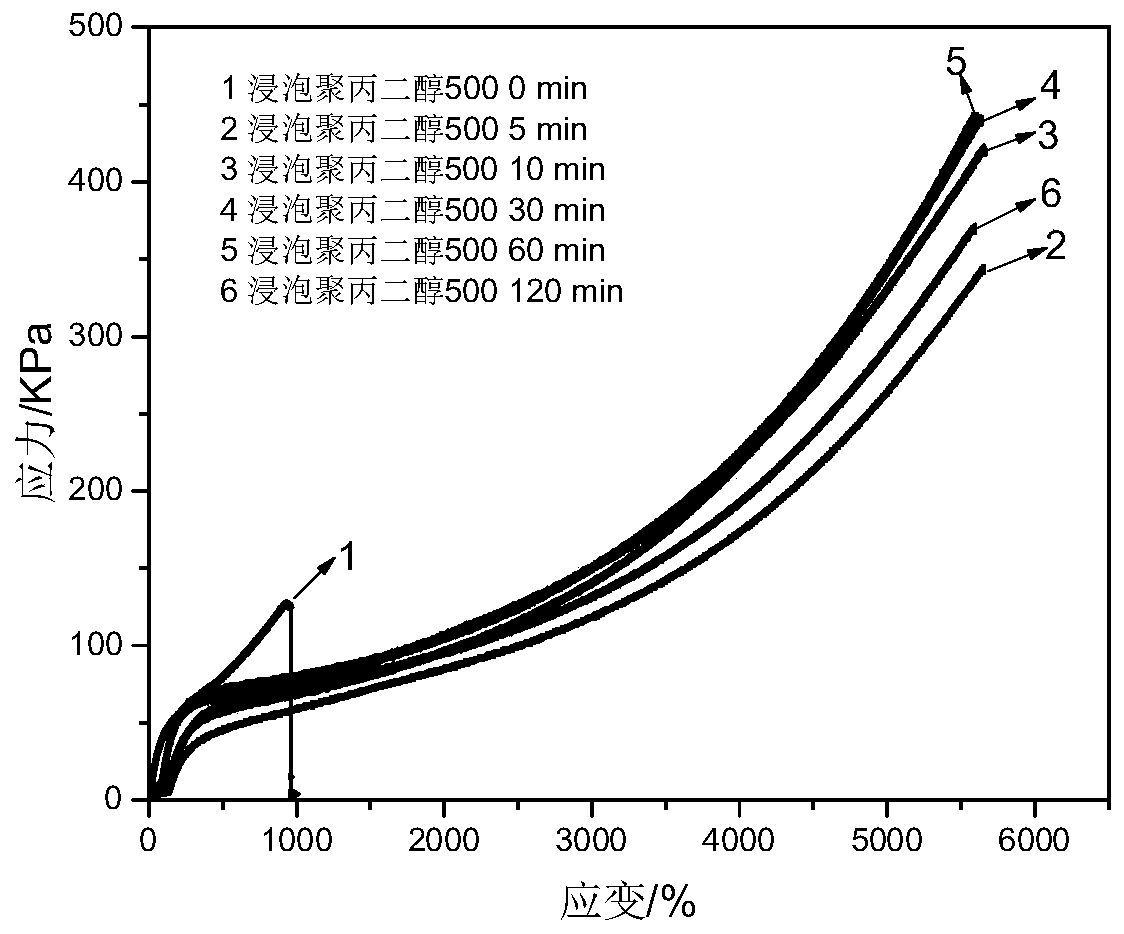

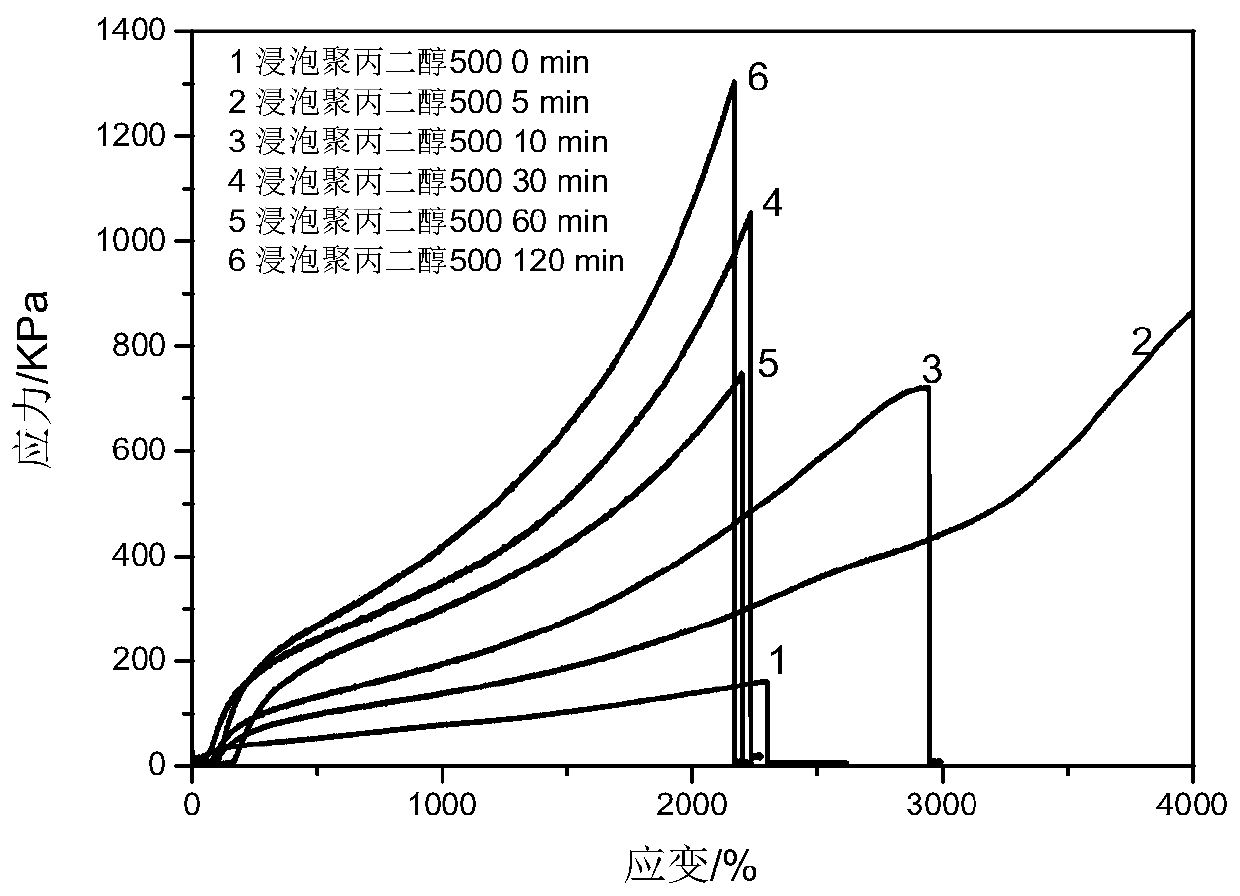

[0052] Weigh 13.8g of acrylamide monomer, dissolve it in 46ml of deionized water, then add 4.0mg of N,N'-methylenebisacrylamide, stir magnetically at room temperature to disperse evenly, then add 32.2mg of ammonium persulfate, and continue stirring Obtain a homogeneous solution, then use a pipette gun to take 22uL tetramethylethylenediamine dropwise into the above mixed solution and keep stirring evenly. After the solution is ultrasonically defoamed, it is introduced into a molding mold and reacted at room temperature for 4 hours to obtain a polyacrylamide hydrogel. Soak the prepared polyacrylamide hydrogel in polypropylene glycol 500 for 30 minutes to obtain a high-strength, freeze-resistant and heat-resistant polyacrylamide organic hydrogel.

[0053] The tensile performance test results are as follows: the tensile ...

Embodiment 2

[0055] The preparation of a high-strength antifreeze and heat-resistant polyacrylamide organic hydrogel specifically comprises the following steps:

[0056] Weigh 13.8g of acrylamide monomer, dissolve it in 46ml of deionized water, then add 8.0mg of N,N'-methylenebisacrylamide, stir it with magnetic force at room temperature to disperse evenly, then add 32.2mg of ammonium persulfate, and continue stirring Obtain a homogeneous solution, then use a pipette gun to take 44uL tetramethylethylenediamine dropwise into the above mixed solution and keep stirring evenly. After the solution is ultrasonically defoamed, it is introduced into a molding mold and reacted at room temperature for 6 hours to obtain a polyacrylamide hydrogel. Soak the prepared polyacrylamide hydrogel in polypropylene glycol 600 for 1 hour to obtain a high-strength, freeze-resistant and heat-resistant polyacrylamide organic hydrogel.

[0057] The tensile performance test results are as follows: the tensile strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com