Stress and luminescence enhanced force-induced luminescence composite film and preparation method

A luminescence enhancement and induced luminescence technology, applied in the field of force-induced luminescence complexes and preparation, can solve the problems of low luminescence intensity and low blue light detection sensitivity, and achieve the effects of improving luminescence intensity, improving mechanical intensity and changing luminescence color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation of TPE-CMP and TPA-CMP can be found in literature: Y.Wei, W.Chen, X.Zhao, S.Ding, S.Han, L.Chen, Polym.Chem.2016, 7, 3983-3988

[0030] The synthesis of linear polymethyl acrylate

[0031] Its main steps are as follows:

[0032] (1) Synthesis of active polymerization initiator: under inert gas protection conditions, ethylene glycol (1.24g, 0.02mol) was dissolved in 100mL of dry dichloromethane, triethylamine (5.8mL, 0.04mol) was added, and ice-water bath conditions Slowly add 2-bromopropionyl bromide (9.8mL, 0.08mol) at room temperature and react overnight at room temperature. The reaction solution is washed with 1M dilute hydrochloric acid solution, saturated aqueous sodium bicarbonate solution and water successively, dried with anhydrous magnesium sulfate, spin-dried, and silica gel The active polymerization initiator (2.78 g, yield 42%) was obtained as a colorless oily liquid by chromatography column separation.

[0033] (2) Single electron transfer...

Embodiment 1

[0044] A method for preparing a force-induced luminescence composite thin film with stress and luminescence enhancement, comprising the following steps:

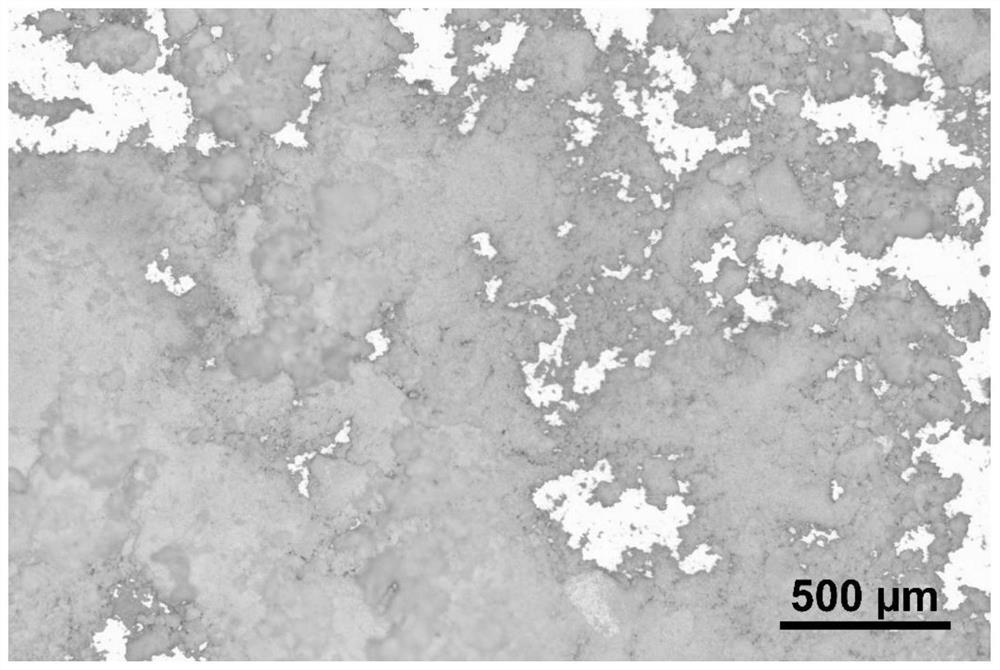

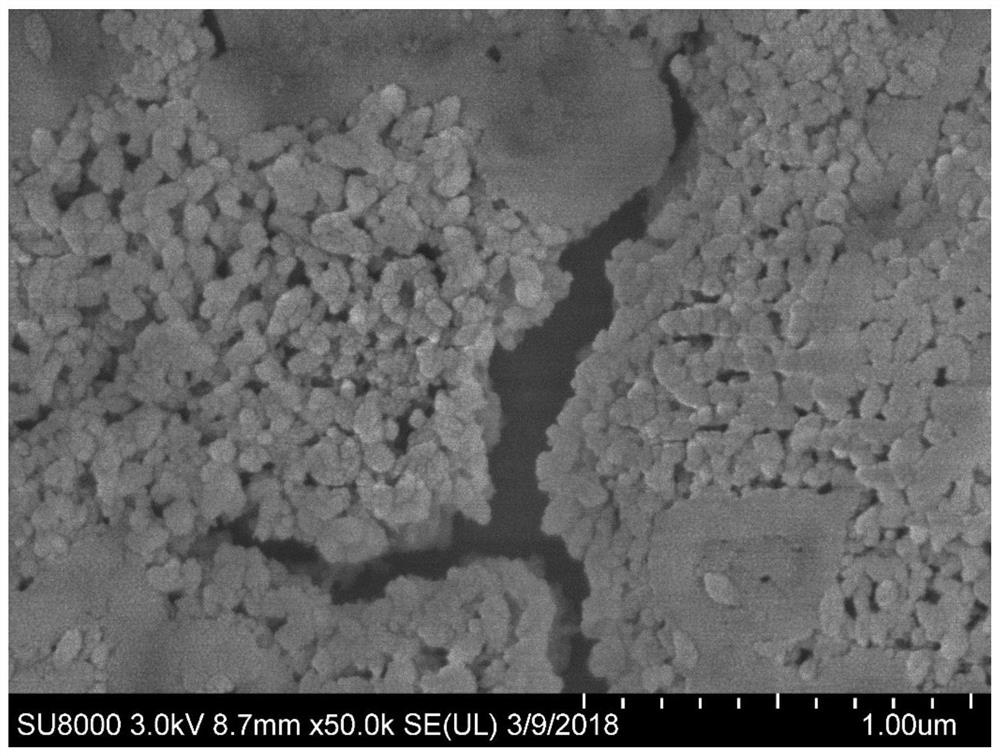

[0045] (1) Add 2mL of N,N'-dimethylformamide to 120mg of conjugated microporous polymer TPE-CMP, use a ball mill, at a speed of 200rpm, ball mill in forward and reverse mode, stop for 3min every 25min, the total The working time is 20h; dilute to 25mL with tetrahydrofuran, and ultrasonicate for 60min under the condition of ultrasonic frequency of 20kHz and amplitude of 25%, to obtain conjugated microporous polymer TPE-CMP dispersion;

[0046] (2) Take 200mg of linear polymethyl acrylate, add the conjugated microporous polymer TPE-CMP dispersion obtained in step (1), heat and stir at 50°C for 12h, the linear polymethyl acrylate and conjugated microporous polymer TPE - The mass ratio of CMP is 100:1;

[0047] (3) Put all the products obtained in step (2) into the mold, add 8 mg of bis-adamantane-substituted 1,2-dioxetane, 16 ...

Embodiment 2

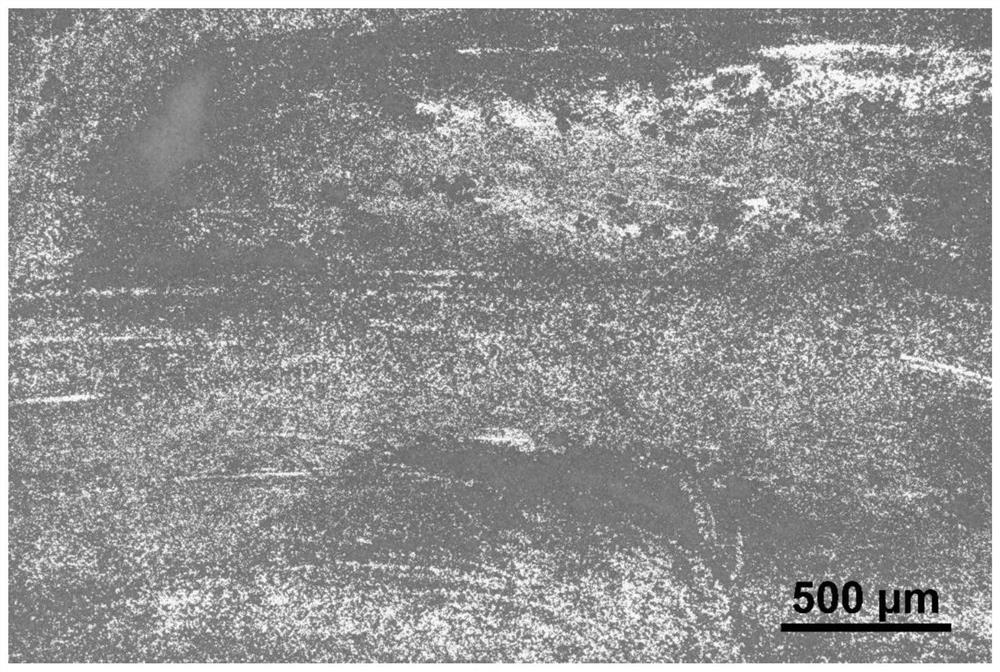

[0058] A method for preparing a force-induced luminescence composite thin film with stress and luminescence enhancement, comprising the following steps:

[0059] (1) Add 3mL of N,N'-dimethylformamide to 120mg of conjugated microporous polymer TPE-CMP, use a ball mill, at a speed of 300rpm, ball mill in forward and reverse mode alternately, stop for 5min every 40min, the total The working time is 24h; dilute to 40mL with tetrahydrofuran, and ultrasonicate for 30min under the conditions of ultrasonic frequency of 20kHz and amplitude of 30%, to obtain conjugated microporous polymer TPE-CMP dispersion;

[0060] (2) Take 200mg of linear polymethyl acrylate, add the conjugated microporous polymer TPE-CMP dispersion obtained in step (1), heat and stir at 56°C for 6h, the linear polymethyl acrylate and conjugated microporous polymer TPE - The mass ratio of CMP is 100:3;

[0061] (3) Put all the products obtained in step (2) into a mold, add 12 mg of bis-adamantane substituted 1,2-dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com