A kind of biopolymer superfine fiber prepared based on centrifugal spinning and its preparation method

A biopolymer and ultra-fine fiber technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc. The effect of improving hydrophilic properties, improving mechanical properties, and promoting tissue healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of biopolymer superfine fiber prepared based on centrifugal spinning, said superfine fiber is made by centrifugal spinning method, and the spinning precursor solution of preparing this superfine fiber is made of chitosan (CS), polyoxyethylene (PEO) Composed of water and water, the fiber diameter of the superfine fiber is 2-5 μm.

[0043] A method for preparing biopolymer ultrafine fibers based on centrifugal spinning, comprising the steps of:

[0044] S1, prepare spinning precursor solution: dissolve 1g chitosan (CS) and 5g polyoxyethylene (PEO) in 44g water, stir until forming homogeneous spinning precursor solution;

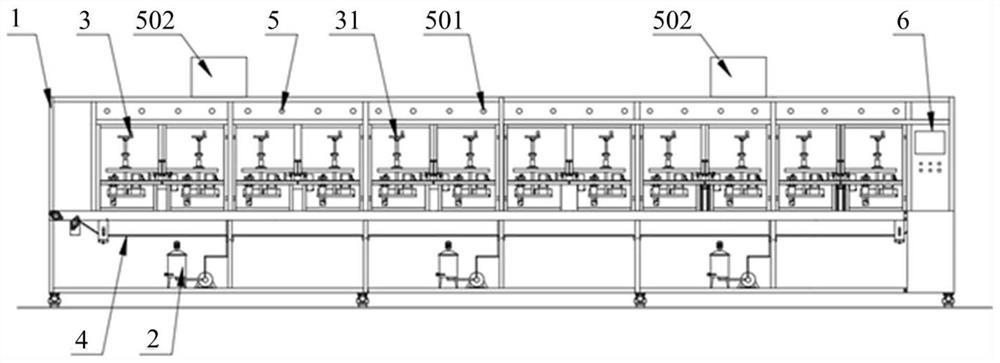

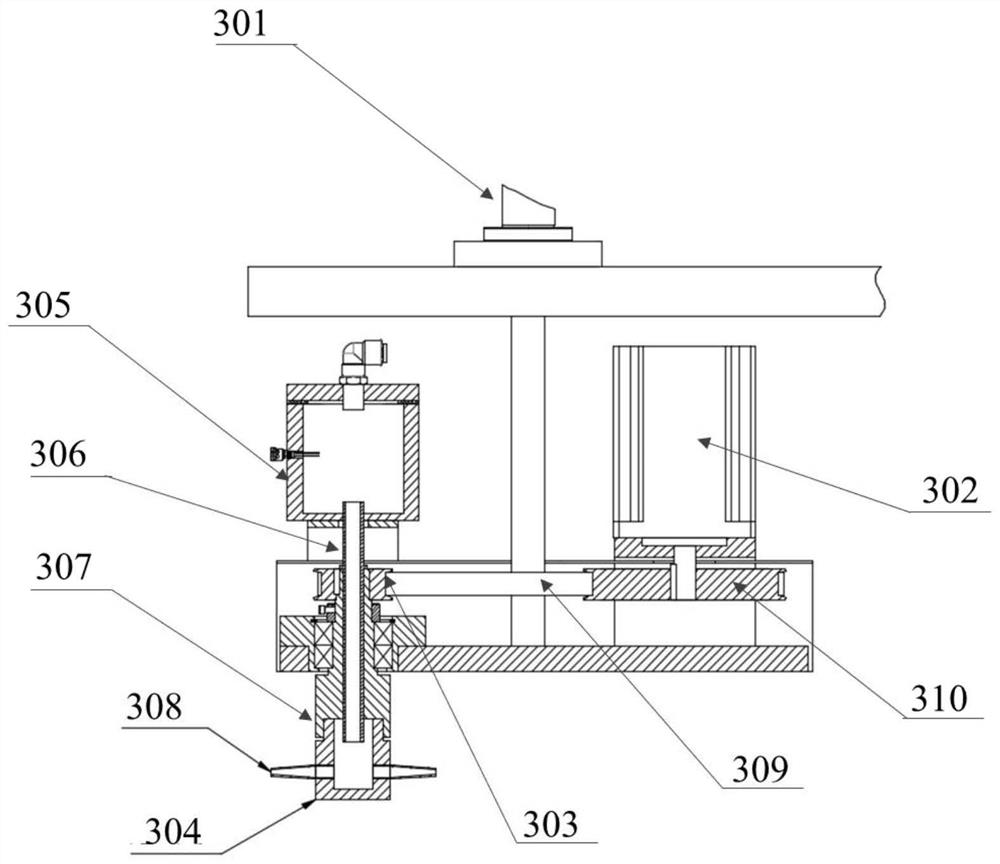

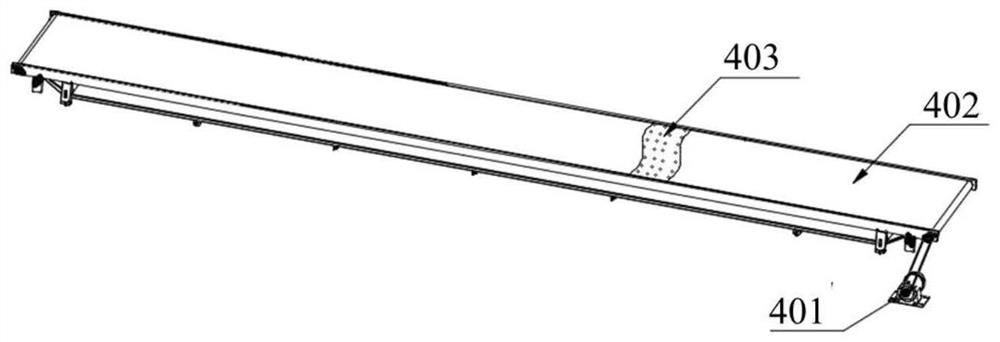

[0045] S2. Centrifugal spinning: inject the above-mentioned spinning precursor solution into a plane-receiving centrifugal spinning device and perform centrifugal spinning at 70°C. The spinneret aperture is 0.16mm, the spinning collection distance is 10cm, and the spinning speed is 8000r / min. , to obtain ultrafine fibers, and then vacuum-dried at...

Embodiment 2-4

[0047] Embodiment 2-4 provides a kind of biopolymer microfiber prepared based on centrifugal spinning, compared with embodiment 1, the difference is that in the ultrafine fiber preparation method step S1 of changing, chitosan (CS) and poly The mass ratio of ethylene oxide (PEO), except for the above differences, other operations are the same, so it will not be repeated here; the specific condition parameters are shown in the table below.

[0048]

[0049]

[0050] Adopt scanning electron microscope to carry out characterizing to the superfine fiber that embodiment 1~4 makes, the result is as follows respectively Figure 4 As shown in (a), (b), (c) and (d), the results in the figure show that with the increase of chitosan mass percentage, the fiber diameter and uniformity first decrease and then increase. When the mass percent of polysaccharide is 6% ( Figure 4 In (c)), the fiber continuity uniformity is the best, the diameter distribution is concentrated, the average f...

Embodiment 5-14

[0052] Embodiments 5-14 provide a kind of biopolymer microfiber prepared based on centrifugal spinning. Compared with Example 3, the difference is that in step S2 of the superfine fiber preparation method, the collection distance of centrifugal spinning, spinning Except for the above differences, other operations are the same for filament temperature, spinneret aperture, and spinning speed, and will not be repeated here; the specific condition parameters are shown in the table below.

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com