Porous alumina nanofiber and preparation method thereof

A porous alumina and nanofiber technology, applied in nanotechnology, inorganic raw material rayon and other directions, can solve the problems of high cost, unfriendly environment, low alumina pore volume, etc., achieve low cost, reduce production cost, prepare simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing porous alumina nanofibers, comprising the following steps:

[0033] (1) Mix active aluminum hydroxide, modifier and water for hydrothermal crystallization, and obtain alumina precursor and hydrothermal crystallization mother liquor after solid-liquid separation;

[0034] (2) Calcining the alumina precursor to obtain porous alumina nanofibers.

[0035] The invention mixes active aluminum hydroxide, a modifying agent and water for hydrothermal crystallization, and obtains an alumina precursor and a hydrothermal crystallization mother liquor after solid-liquid separation. In the present invention, the activated aluminum hydroxide is obtained by activating aluminum hydroxide through an activation atmosphere; the activation atmosphere preferably includes one or more of hydrogen, oxygen, nitrogen, air, carbon dioxide, argon and helium; The activation temperature is preferably 100-800° C., more preferably 200-400° C., and the acti...

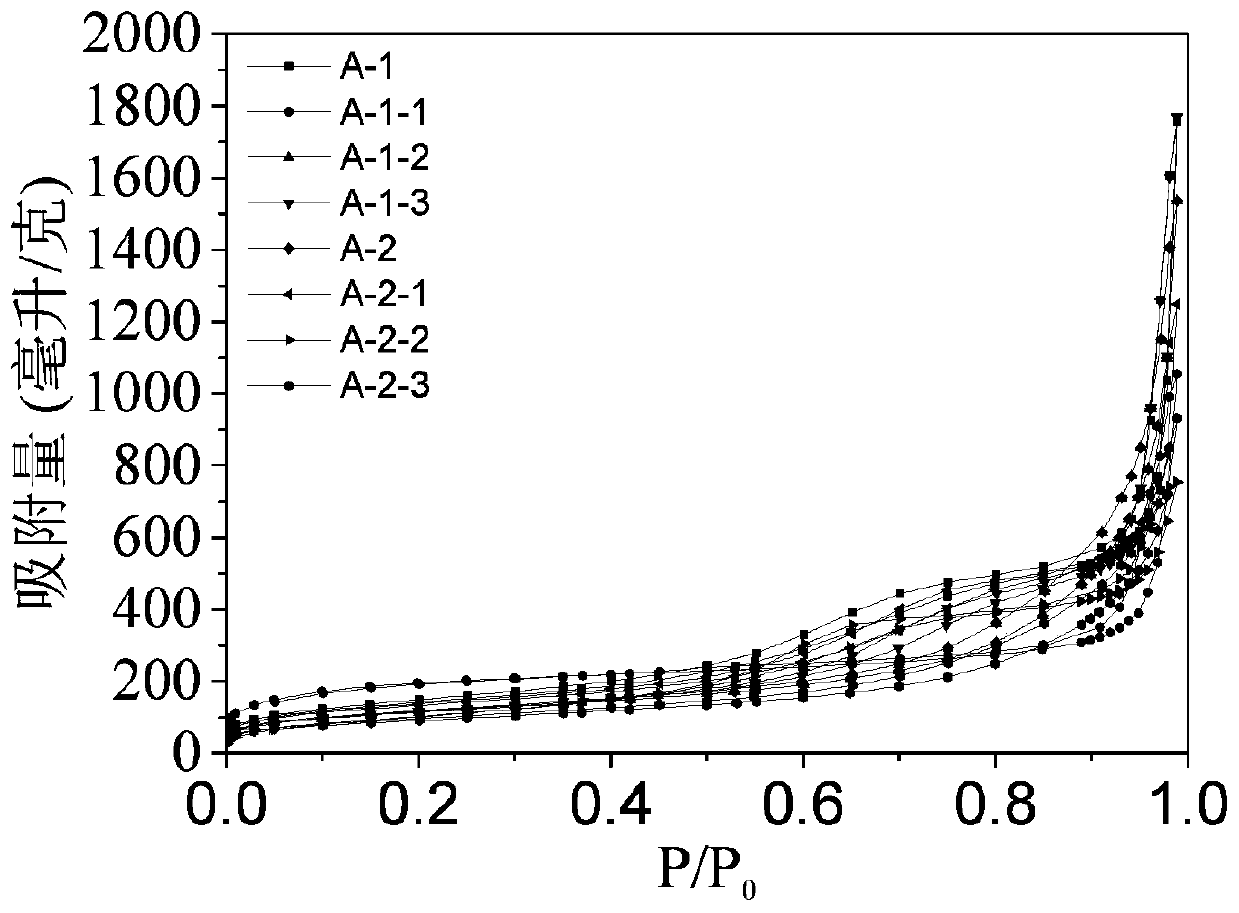

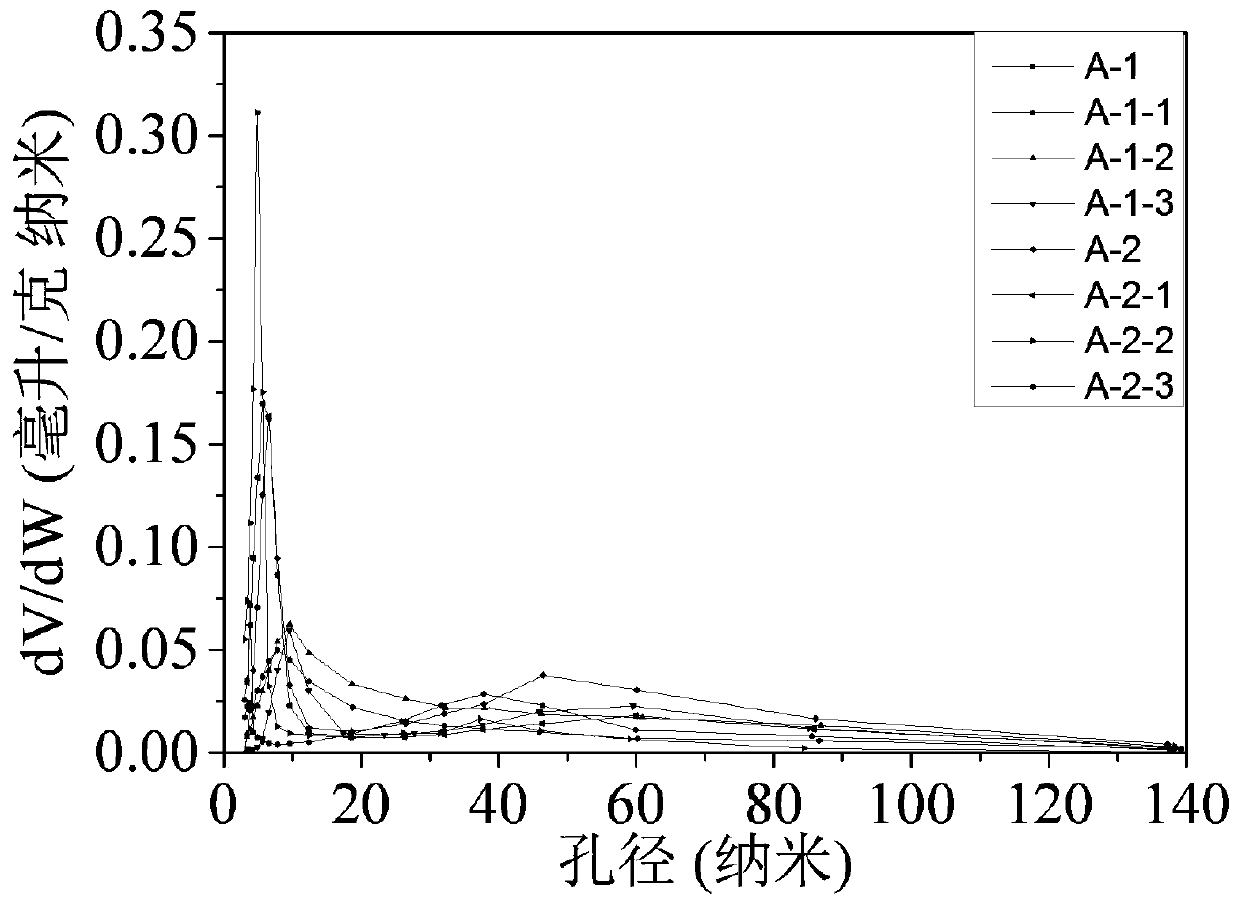

Embodiment 1

[0045] At room temperature, prepare a biuret solution with a mass fraction of 30%, and then add activated aluminum hydroxide powder according to the molar ratio of biuret to Al of 10:1 (activate aluminum hydroxide at 100°C for 5h under a nitrogen atmosphere), Stir evenly, transfer to a crystallization kettle, crystallize at 80°C for 14 hours, suction filter and wash the solid obtained after crystallization, and dry at 80°C for 12 hours to obtain an alumina fiber precursor, which is designated as A-1, The mother liquor obtained after crystallization is recorded as mother liquor (1). The obtained A-1 specific surface area is 505.4m 2 / g, the pore volume is 2.7cm 3 / g.

[0046] The obtained A-1 solid was heated up to 650°C at a heating rate of 2°C / min in an air atmosphere, and then roasted at a constant temperature for 6 hours to obtain porous alumina nanofibers, denoted as Al 2 o 3 -1, the specific surface area is 318.3m 2 / g, the pore volume is 2.10cm 3 / g.

Embodiment 1-1

[0048] Add biuret to the mother liquor (1) obtained in Example 1, then add the same amount of active aluminum hydroxide powder as in Example 1 (aluminum hydroxide is activated at 150° C. for 4 h under a carbon dioxide atmosphere) and water, and stir evenly. Wherein the molar ratio of added biuret to Al in added activated aluminum hydroxide is 4:1, and the molar ratio of added water to added Al in activated aluminum hydroxide is 20~30:1; Crystallize in a crystallization kettle at 130°C for 12 hours, filter and wash the solid after crystallization, and dry at 100°C for 12 hours to obtain a nanofibrous alumina precursor, which is denoted as A-1-1, and the crystallized The mother liquor is recorded as mother liquor (2). The obtained A-1-1 specific surface is 325.9m 2 / g, the pore volume is 1.42cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com