Light absorption heating blended yarn

A light-absorbing heat-generating and blended yarn technology, which is applied in the yarn field, can solve the problems affecting the breathable and moisture-permeable performance of fabrics, and achieve good light-absorbing and heat-generating properties, easy production and implementation, and excellent thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

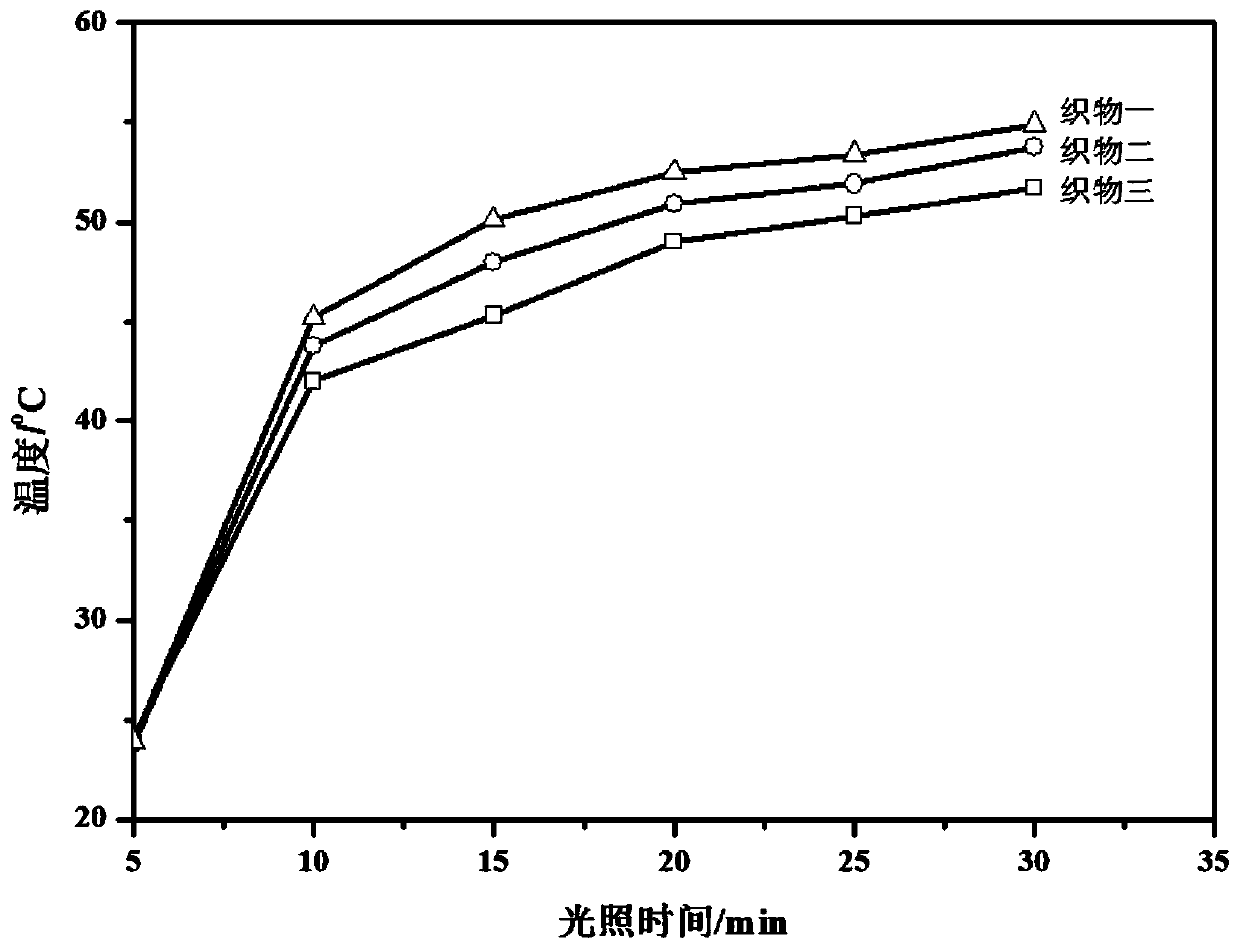

Embodiment 1

[0015] A light-absorbing and heat-emitting blended yarn, prepared from the following fibers in mass percentage: 25% cotton fiber, 35% nano-heating acrylic blended staple fiber, 20% polyester hollow fiber and 20% spandex fiber, wherein the nano-heating acrylic fiber The preparation process of the blended staple fiber is: Step 1, the modified acrylic staple fiber prepared by blending nano-ceramic particles, nano-volcanic rock powder and acrylic fiber spinning solution; Step 2, mixing the modified acrylic staple fiber with cotton fiber , polypropylene fiber is blended, and the blending composition percentage of described modified acrylic fiber staple fiber and cotton fiber, polypropylene fiber is 40%: 30%: 30%, makes nano-ceramic acrylic fiber blended staple fiber; Described light-absorbing and heating blended yarn The preparation method of the yarn is as follows: interweaving and blending the nano-ceramic acrylic fiber blended staple fiber prepared above with cotton fiber, polyes...

Embodiment 2

[0021] A light-absorbing and heat-generating blended yarn prepared from the following fibers in mass percentage: 20% cotton fiber, 30% nano-heating acrylic blended staple fiber, 15% polyester hollow fiber and 35% spandex fiber, wherein the nano-heating acrylic fiber The preparation process of the blended staple fiber is: Step 1, the modified acrylic staple fiber prepared by blending nano-ceramic particles, nano-volcanic rock powder and acrylic fiber spinning solution; Step 2, mixing the modified acrylic staple fiber with cotton fiber , polypropylene fiber is blended, and the blending composition percentage of described modified acrylic fiber staple fiber and cotton fiber, polypropylene fiber is 40%: 30%: 30%, makes nano-ceramic acrylic fiber blended staple fiber; Described light-absorbing and heating blended yarn The preparation method of the yarn is as follows: interweaving and blending the nano-ceramic acrylic fiber blended staple fiber prepared above with cotton fiber, polye...

Embodiment 3

[0027] A light-absorbing and heat-emitting blended yarn, prepared from the following fibers by mass percentage: 30% cotton fiber, 40% nano-heating acrylic blended staple fiber, 25% polyester hollow fiber and 5% spandex fiber, wherein the nano-heating acrylic fiber The preparation process of the blended staple fiber is: Step 1, the modified acrylic staple fiber prepared by blending nano-ceramic particles, nano-volcanic rock powder and acrylic fiber spinning solution; Step 2, mixing the modified acrylic staple fiber with cotton fiber , polypropylene fiber is blended, and the blending composition percentage of described modified acrylic fiber staple fiber and cotton fiber, polypropylene fiber is 40%: 30%: 30%, makes nano-ceramic acrylic fiber blended staple fiber; Described light-absorbing and heating blended yarn The preparation method of the yarn is as follows: interweaving and blending the nano-ceramic acrylic fiber blended staple fiber prepared above with cotton fiber, polyest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com